With the in-depth promotion of the "Occupational Disease Prevention and Control Law" and the "14th Five-Year Plan" occupational disease prevention and control plans of various provinces and cities, workplace dust hazard monitoring and prevention and control have become the core tasks of disease control departments. Taking mining, building materials, metallurgy, chemical industry and other industries as examples, accurate measurement of dust concentration, distribution and propagation characteristics is the key to assessing occupational disease risks.

Traditional dust monitoring methods have many limitations in terms of accuracy, real-time and comprehensiveness, while the PIV measurement system based on particle image velocimetry technology provides a new solution for dust monitoring.

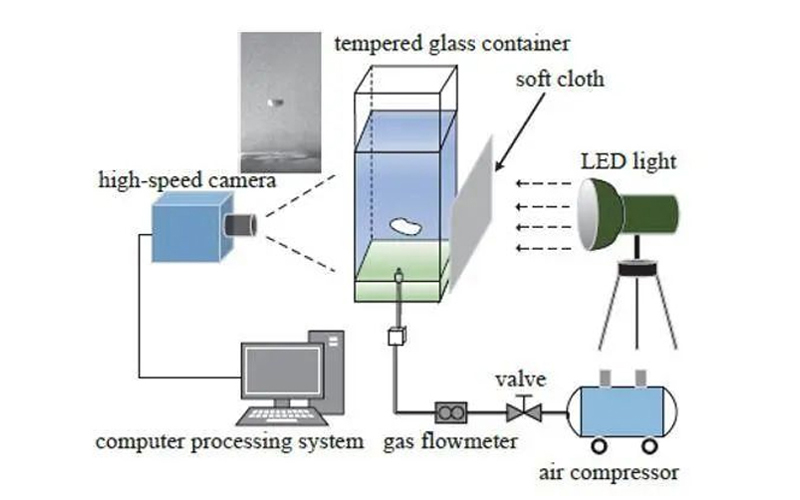

PIV technology is an advanced non-contact flow field measurement method. By spreading tracer particles in the dust flow field, a high-speed camera is used to continuously capture images of particle displacement changes in a short period of time, and then through image processing and related algorithm calculations, the velocity vector field, vortex field and other parameters of the dust are obtained.

The differentiated value points of Revealer PIV measurement system in dust monitoring:

1) Non-contact measurement: avoid the interference of traditional contact measurement methods on the flow field, ensure data accuracy and improve the safety and convenience of operation.

2) Real-time dynamic measurement: high-speed cameras can capture the dynamic change process of dust in real time with microsecond time resolution, so as to facilitate the timely detection of excessive dust concentration or abnormal diffusion.

3) Visual measurement: support visual measurement of parameters such as dust concentration, velocity, turbulence intensity, vortex cloud map, etc.

4) High-precision measurement: It supports capturing tiny displacements of dust particles, with measurement accuracy up to sub-pixel level, and accurately assesses dust concentration and diffusion patterns.

1) Build a PIV system, select Revealer high-speed cameras at key locations such as near the dust source and ventilation diffusion path, and ensure that the shooting angle covers the monitoring area.

2) According to the experimental environment, experimental type, and experimental range, add tracer particles or directly use the dust in the environment as the analysis object, and match the appropriate PIV high-speed camera, exposure time, laser light source and other parameters.

3) After starting the system, the PIV measurement system collects sequential images of dust particles in the flow field, and uses RFLOW flow field analysis software for cross-correlation calculation to obtain the velocity vector field, further solve the curl of the velocity vector field to obtain the vorticity field, and obtain the dust concentration distribution cloud map and other results through the analysis of the image gray value.

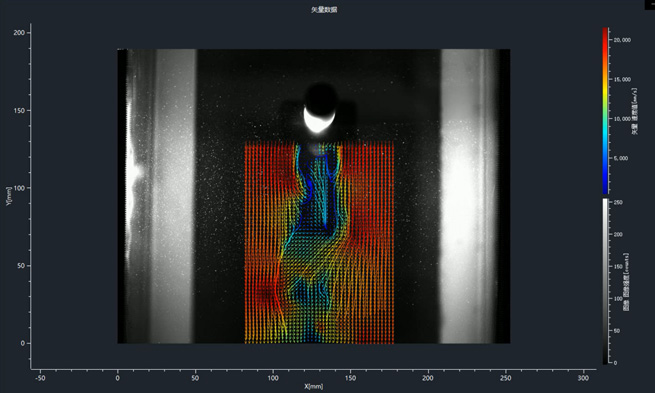

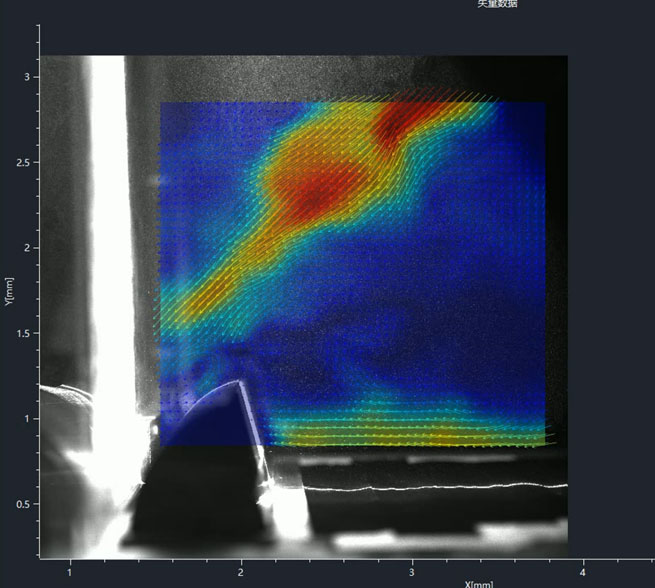

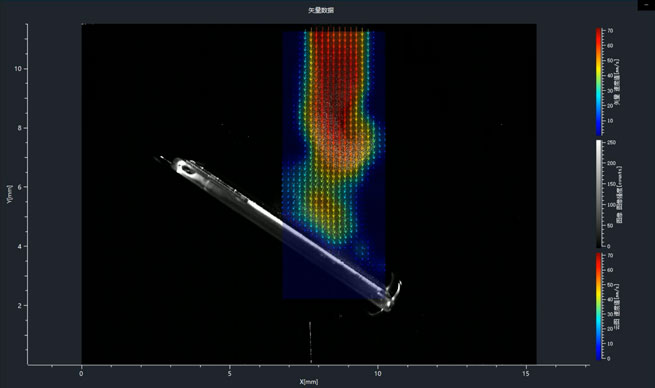

4) In data application, the velocity vector field visualizes the movement direction and speed of dust in the workplace, helps identify the main diffusion path and high-speed movement area of dust, and provides a reference for setting up dust barriers and ventilation facilities. The vortex field reveals the vortex structure in the dust flow field. The vortex may cause local accumulation or secondary diffusion of dust. By analyzing the vortex distribution, the equipment layout and ventilation system design can be optimized to reduce the dust residence time. The dust concentration cloud map visualizes the distribution of dust concentration at different locations in the workplace, making it easier to identify high-concentration risk areas and take targeted measures such as local ventilation and spray dust reduction.

Case 1: The study of flow fields in tunnels (such as mine tunnels, ventilation ducts, traffic tunnels, underground facilities, etc.) plays an important role in engineering, safety and environmental fields. Revealer high-frequency PIV flow field measurement system analyzed the flow field in a mine tunnel and provided intuitive and visual guidance data for optimizing ventilation design, ensuring that fresh air is effectively delivered to the working surface, while dust and other harmful gases (such as gas, carbon monoxide) are discharged in time to avoid explosion, suffocation or occupational disease risks.

Case 2: There are various forms of air supply and return in the fresh air system. In this experiment, we used the Revealer PIV flow field measurement system to measure the flow field near the return air outlet in the top supply, floor supply, and floor return rooms under a slightly positive pressure environment. Through the visual measurement of the return air outlet flow field, it helps to optimize the "directional exhaust" system to ensure that the polluted air in the factory is captured by the return air outlet first to avoid spreading to the corridor or other areas. At the same time, the visualization advantage of the PIV flow field measurement system is conducive to discovering the possible formation of local "air flow short circuits", which makes it impossible for pollutants (such as toxic and harmful gases, CO₂, PM2.5, and viral aerosols) to be effectively discharged from the room.

Case 3: Studying the flow field (airflow and droplet motion distribution) of aerosol spray dust removal systems is of great significance for improving dust removal efficiency, reducing energy consumption, optimizing equipment design, and ensuring operational safety in high-dust environments. Revealer's high-frequency PIV flow field measurement system visualizes the flow field of aerosol spray dust removal equipment and studies the interaction between droplets and dust particles (such as inertial collision, interception, and diffusion capture), which is conducive to optimizing droplet size (usually 20~200 μm is the most efficient) and spray density, and improving capture rate; secondly, in high temperature or high wind speed environments, droplets may evaporate and fail before contacting dust. Revealer's PIV measurement system optimizes the initial velocity and particle size of droplets, and provides objective data support for balancing sedimentation time and evaporation rate.

Revealer PIV measurement system breaks through the limitations of traditional monitoring methods and provides high-precision, real-time, and comprehensive dust monitoring data, which can be used as one of the standard tools for occupational disease hazard monitoring.

Based on the dust monitoring data collected and analyzed by the PIV system, the disease control departments of local governments can accurately grasp the laws of dust hazards in key industries and workplaces of different enterprises, and provide objective data support for the formulation of scientific and reasonable prevention and control measures, standards, and guidelines.