Laser welding, as a high-precision and high-efficiency connection technology, is widely used in the fields of new energy vehicles, semiconductor packaging, and aerospace component processing. The formation of dynamic pitting in the molten pool during laser welding will affect the strength and sealing of the welded joint. The dynamic stability of the pitting also determines the quality of the weld and the probability of defects such as pores and cracks.

Traditional detection methods such as metallographic sections are difficult to capture the pitting formation process and characteristics in real time and intuitively. High-speed camera technology, with microsecond resolution, accurately captures the dynamic behavior and evolution of pitting, providing real-time data support for welding process optimization.

Recently, Qianyanlang technical engineers and researchers from a key welding laboratory of a university jointly carried out a laser welding pitting observation experiment based on high-speed camera technology.

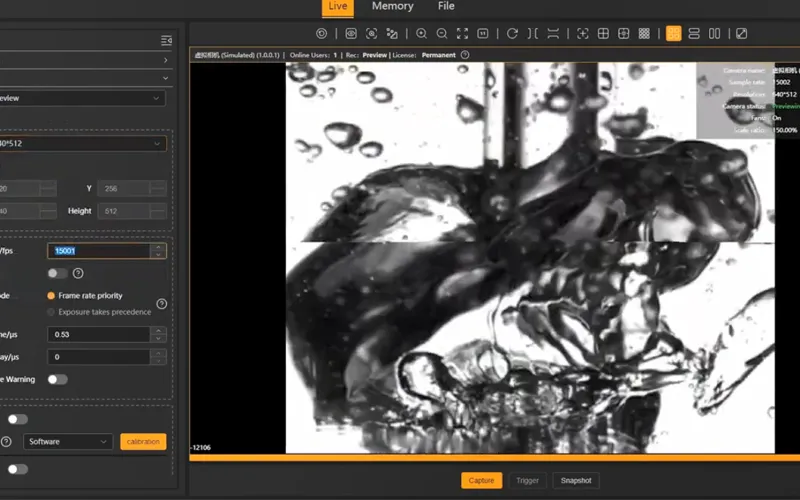

Figure 1 Etching pit

1) Real-time observation of the formation and development of pitting during laser welding, and acquisition of dynamic image information of pitting.

2) Analyze the changing rules of characteristic parameters such as pitting shape, size, and position under different welding conditions.

3) Explore the causes and influencing factors of pitting, and establish a relationship model between pitting and welding process parameters.

1) High-speed camera: Revealer M230M, sampling frequency 3000 frames/second, resolution 1920×1080,

equipped with narrow-band filter to suppress plasma interference.

2) Laser welding system: wavelength 1064nm, power 1.5kW, equipped with a six-axis robot to accurately control the welding path.

3) Synchronous controller: time accuracy 1μs, used for triggering synchronization between laser and high-speed camera.

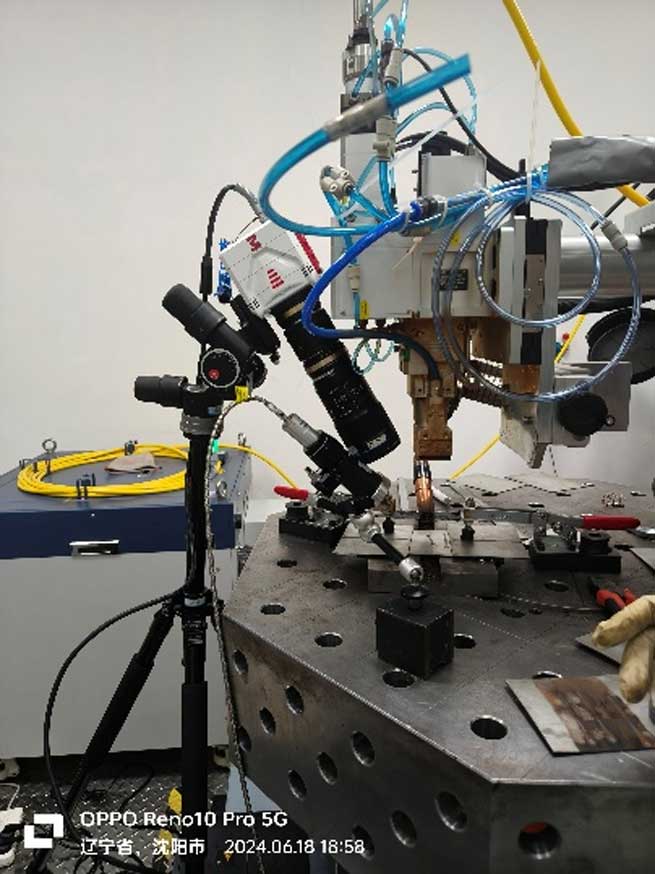

Figure 2

1) Install the high-speed camera and the laser head coaxially and forwardly, with the viewing angle perpendicular to the welding direction, and use an 808nm laser as the fill light source to fill light from the front.

2) Set the acquisition frame rate of the high-speed camera to 3000fps, the exposure time to 5μs, and adjust the position and angle of the high-speed camera (see Figure 2 for details) to clearly capture the welding field area of 3×2cm.

3) Set the laser welding process parameters, use 1.5kW continuous wave mode, and the welding speed is 50~80mm/s.

4) Start the laser welding equipment and the high-speed camera to shoot synchronously in real time, record the entire welding process (see the video for details, video is required, not GIF, Jiaxin will adjust it, the video can be viewed after clicking), observe the dynamic characteristics of the pitting, the stable pitting is "spindle-shaped", the depth fluctuation range is ±0.1mm, the frequency is about 200Hz, and splash particles are generated.

5) The image analysis software supporting the high-speed camera can be used to process and analyze the sequence images. The dynamic characteristic parameters such as the appearance time, duration, growth rate, shape change of the pits can be extracted, and the correlation analysis can be carried out with the welding process parameters.

This experimental study provides a high-precision, high-speed, dynamic observation method for the formation and development of pits for laser welding process development, which is suitable for application scenarios such as new energy vehicle battery sealing welding, semiconductor packaging, and aerospace component connection. In the future, high-speed camera sequence image data combined with AI numerical simulation methods can more accurately predict the pitting phenomenon in the laser welding process and realize real-time closed-loop control of welding quality.

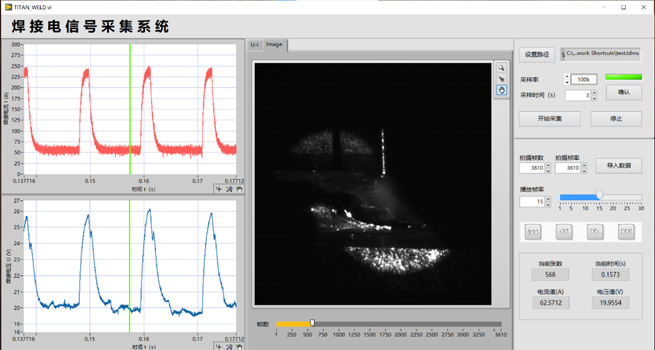

Qianyanlang welding current and voltage analysis module records arc voltage and welding current during arc welding, synchronously triggers high-speed cameras, realizes digital recording of welding electrical signals and online image monitoring, and can be applied to welding process research, welding material evaluation and improvement, welding power supply characteristic detection and adjustment, welding quality analysis and other fields.

Revealer welding current and voltage module parameter table↓↓↓

Module | Welding current and voltage analysis module |

Application scenarios | arc welding, gas metal arc welding, submerged arc welding, plasma arc welding, TIG welding, etc. |

Current detection range | ±1000A |

Voltage detection range | ±100V |

Electrical signal sampling frequency | 50kHz |

High-speed camera frame rate | 3000 |

Image resolution | 1920×1080 |

Synchronization mode | Electrical signal and camera synchronous trigger |

Analysis and measurement | Electrical signal storage, electrical signal display, image playback, data export |

| Synchronous acquisition and display | Supports synchronous acquisition, storage, and display of welding current and voltage signals |