Large, load-bearing aluminum alloy components in the aerospace industry are developing toward lightweight, high-strength, and integrated manufacturing. While traditional MIG/MAG arc additive manufacturing technologies offer high deposition rates and excellent material adaptability, they suffer from issues such as high heat input, large spatter, porosity, and thermal cracking, which restrict both forming quality and mechanical property stability.

CMT (Cold Metal Transfer) technology, with its low heat input and precise droplet control, offers a new solution for high-quality additive manufacturing of aluminum alloys.

To gain a deeper understanding of the transient behavior of droplet transfer during CMT arc additive manufacturing and provide a process basis for near-net-net-net forming of large, complex components, an additive manufacturing laboratory utilized a Revealer S1315M 10,000-fps High Speed Camera to visualize and analyze the underlying mechanisms of droplet dynamics and forming quality.

2.1 Experimental Objectives

Capture the transient processes of droplet short-circuiting, retraction, bridge necking, and separation;

Analyze the timing characteristics, deformation, and dynamic behavior of droplet transfer;

Verify the advantages of CMT technology in reducing heat input, suppressing spatter, and stabilizing transfer.

2.2 Experimental Equipment

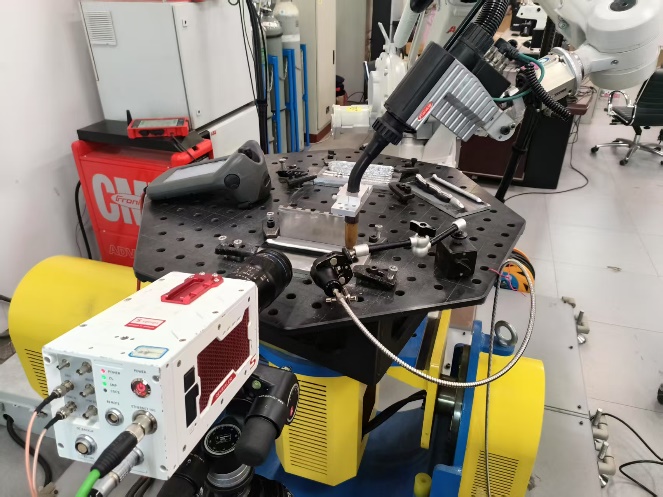

High Speed Camera: Revealer S1315M, 1280 × 1024, capable of high-speed acquisition at 15,000 fps for full-frame resolution.

Optical lens: 100 mm f/2.8 macro lens, enabling micron-level imaging of droplet locations.

Light source: 850 nm laser light source, used to eliminate arc interference and enhance the droplet profile. 2.3 Experimental Setup

2.3 Experimental setup

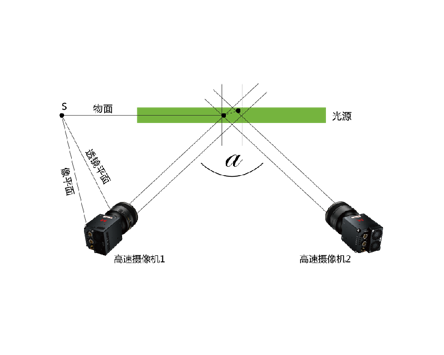

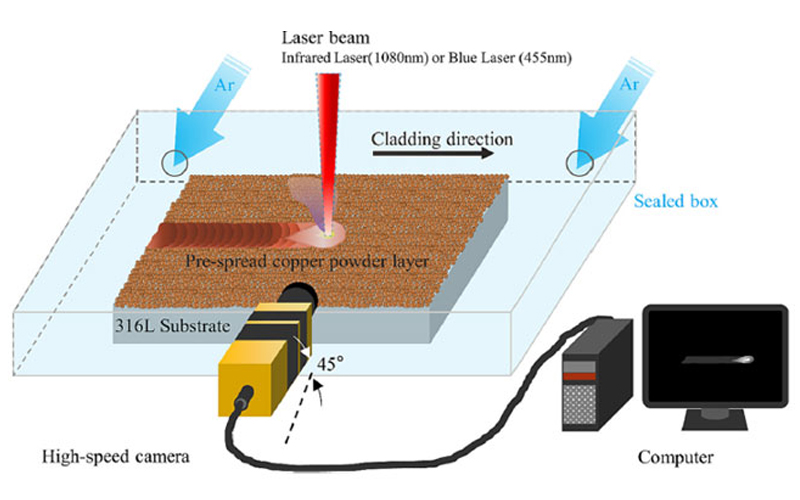

A Revealer High Speed Camera S1305M was positioned 15 cm above the object. A laser light source was positioned on the same side at a 45° angle. The macro lens was adjusted to focus on the welding torch wire. The resolution, frame rate, and exposure time parameters were set according to the experimental requirements.

Figure1

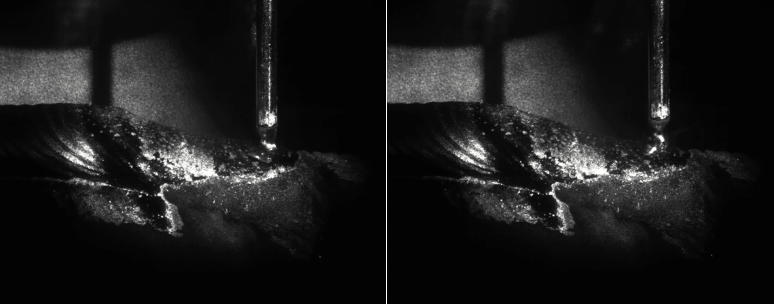

Frame-by-frame analysis of video images captured by a Revealer High Speed Camera S1315M reveals that the CMT droplet transfer cycle can be divided into three phases: droplet retraction, bridge necking, and droplet separation.

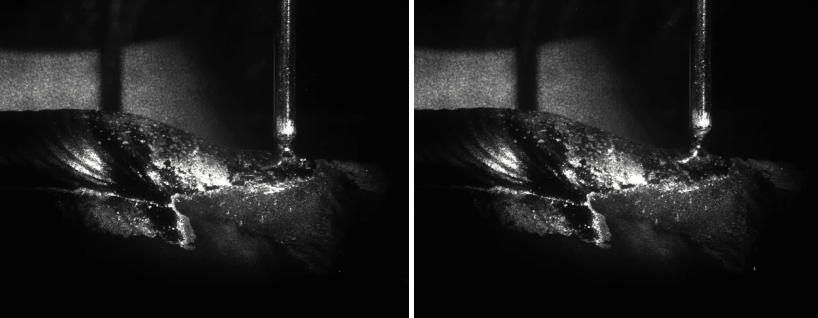

Droplet short-circuiting and wire retraction phase: When the droplet contacts the weld pool, the current rises rapidly. The system detects a short-circuit signal and actively triggers the torch retraction. The high-speed images clearly show the wire's "reverse motion" at the moment of contact, as shown in Figure 2.

Figure2

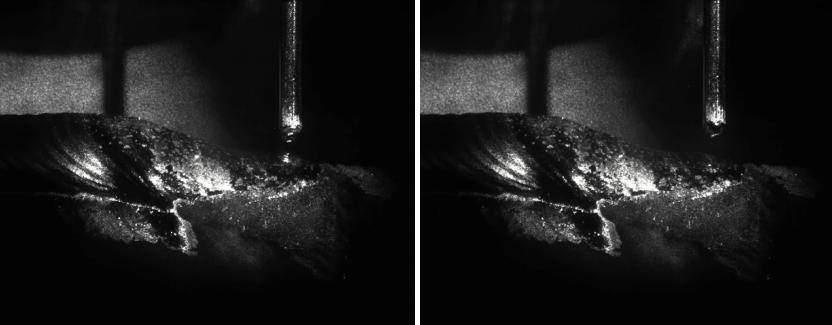

Liquid bridge necking stage: Under the action of the retraction force, a liquid metal bridge forms between the molten droplet and the welding wire. Due to surface tension and electromagnetic contraction forces, the liquid metal on the liquid bridge surface contracts inward, and the middle part of the liquid bridge is squeezed and gradually becomes thinner, with the diameter shrinking from an initial 0.8mm to 0.1mm. The shrinkage shape captured by the High Speed Camera shows a distinct waist-like shape (Figure 3).

Figure3

Droplet separation stage: When the liquid bridge shrinks to the point where it can no longer withstand its own tension and external forces, it breaks and the droplet separates from the molten pool. This moment of breakage is captured by a High Speed Camera, and no obvious metal particles are splashed (Figure 4).

Figure4

The experiment used a Revealer S1315M 10,000-fps Camera to clearly record the transient behavior of droplet retraction, liquid bridge necking, and droplet separation during the CMT additive manufacturing process, providing visual evidence for research into the CMT process mechanism:

CMT achieves a "cold transition" through mechanical retraction and surface tension-driven separation, minimizing spatter throughout the process and addressing forming defects caused by the high thermal conductivity and strong oxidizing properties of aluminum alloys.

CMT parameters such as droplet cycle, droplet size, and droplet separation speed can be quantitatively analyzed using sequential images captured by the high-speed camera. This allows for precise matching of wire feed speed, retraction amplitude, and arc energy parameters, addressing the challenges of additive manufacturing accuracy and performance consistency.