Aero-engine blades withstand enormous aerodynamic loads and centrifugal forces under high-speed rotating conditions. Their strain distribution and dynamic response are directly related to the performance and safety of the engine. Finite element simulation can provide blade simulation data, but the lack of full-field dynamic response data under real operating conditions restricts blade design and verification. The R&D team of a new type of blade introduced high-speed imaging technology and digital image correlation (DIC) technology from HF Agile Device Co.,Ltd to conduct non-contact strain measurement, aiming to obtain the strain distribution and vibration characteristics of the blades under actual working conditions.

2.1 Obtain the full-field strain distribution of blades at different rotational speeds using DIC technology to verify the accuracy of the simulation model.

2.2 Analyze the strain gradient from the blade root to the blade tip and evaluate the rationality of structural stress.

2.3 Evaluate the applicability of the DIC measurement scheme under vacuum environment and high-speed rotating conditions.

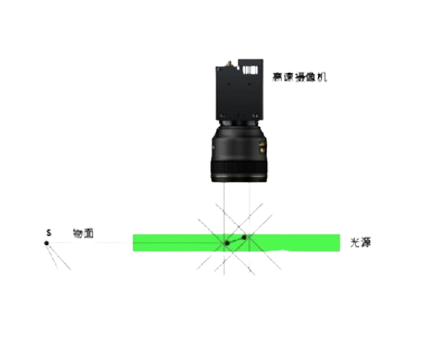

The experiment adopted high-speed digital image correlation (DIC) equipment from HF Agile Device Co.,Ltd, including 2 Revealer NEO 25 high-speed cameras. These cameras feature a acquisition frame rate of 25,000 frames per second at a resolution of 1280×1024. They were installed directly below the vacuum chamber, with the blades placed inside the chamber. The two high-speed cameras formed an appropriate angle, and were equipped with 100mm telephoto lenses and polarizers to capture local dynamic images of the blades and eliminate reflection. The surface of the blades was marked with 2mm speckles using a matte pen to provide the random texture features required for DIC software analysis and calculation. A phase-locking device was activated during the entire shooting process of the high-speed cameras to ensure the stability of the shooting area without being affected by blade rotation.

4.1 Strain Characteristics Predicted by FEA Simulation Model:

Spatial distribution: The blade root has the maximum strain due to strong constraints, and the strain decreases from the blade root to the tip along the spanwise direction, forming a smooth transition.

Load response: The strain increases with the square of the rotational speed, showing an overall stepped upward trend.

Magnitude range: The peak axial strain is approximately 1000 με, which meets the requirements of the material's elastic limit.

4.2 Analysis Results Based on DIC Instrument Measured Data:

The single-frame strain cloud map shows that the strain field from the blade root to the tip generally presents a gradient transition characteristic: the strain is large at the blade root and gradually decreases towards the tip. The overall trend is consistent with the simulation expectation.

In the steady-state phase of each rotational speed, the average value of the full-field average radial strain increases with the rotational speed, showing a stepped upward trend. This is basically consistent with the simulation expectation, indicating that the DIC instrument successfully captures the macro-deformation response caused by centrifugal loads.

The peak strain level ranges from 800 to 1100 με, which is consistent with the simulated expected magnitude, verifying the quantitative accuracy of DIC measurement.

For a detailed analysis of the experiment on measuring blade vibration modes using high-speed imaging technology and digital image correlation technology, please see https://mp.weixin.qq.com/s/Bll4k1CndfXvpFd1i3U33Q