Background

In the field of water treatment, electrocoagulation technology has become a hot topic in the fields of water treatment and river dredging due to its simple operation, no secondary pollution, high efficiency and low cost. However, there is still a lack of systematic research on the mechanism of the influence of bubble movement and flow field disturbance on flocculation effect.

Recently, a joint research team from Qinghai University and Tsinghua University conducted an experimental study based on a particle image velocimetry system (PIV system), revealing the coupling law between bubble dynamics and flow field evolution during electrocoagulation.

For details, please see the paper "Characteristics and Controlling Factors of Electrocoagulation Flow Field and Sediment Settling Effect".

Experimental Platform

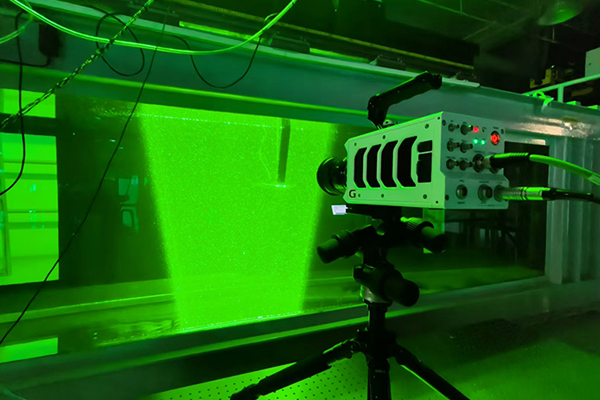

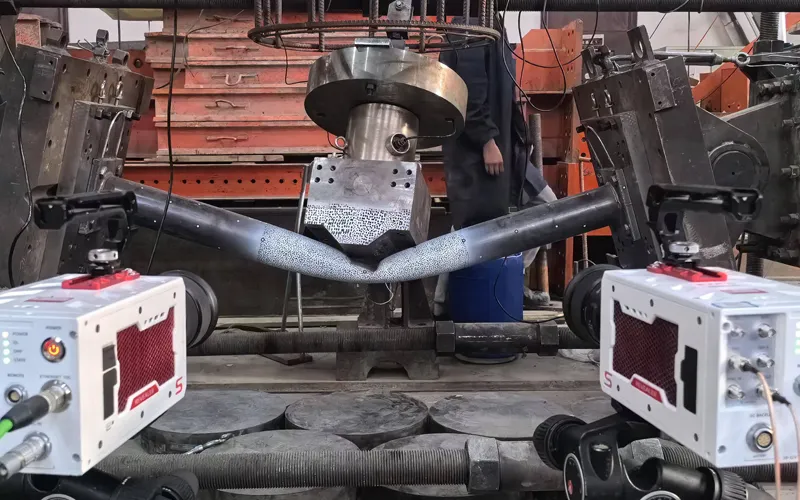

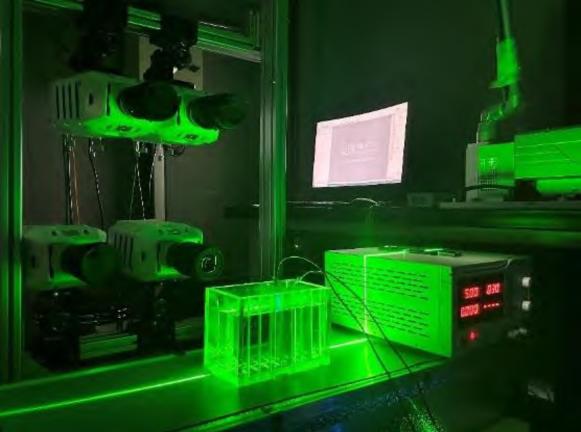

It consists of the Revealer PIV system and the flocculation system.

1. PIV system: 4 Revealer PIV high-speed cameras with a resolution of 2560×1920, a frame rate of 2000 fps, and a PIV cross-frame time of 300 ns, used to capture the transient motion of bubbles. Pulsed laser with an energy of 30 mJ and a frequency of 1 kHz is used to vertically illuminate the experimental observation area and clearly image the tracer particles. Synchronous controller is used to coordinate the timing of the high-speed camera and the laser, as shown in Figure 1.

Figure 1: Revealer PIV system

2. Electrocoagulation system: flocculation tank, size 180 mm × 110 mm × 130 mm, aluminum electrode plates, spacing 40 mm, adjustable DC power supply 0~30 A, resolution 0.01.

Experimental procedures

1. Experimental Preparation and Design

1.1 The experimental solution was prepared by 1.3 L of pure water and 1.3 g of NaCl , and the solution temperature was ambient temperature (20°C). In the experiment, the sediment samples were taken from the upper reaches of the Yellow River. After cleaning and drying, 2.6 g of sediment particles were added to the experimental solution. The sediment concentration of the solution was 2 g/L. After stirring evenly, it was left for 60 s before the experiment began.

1.2 Set 9 groups of current density (10~50 A/m², step size 5 A/m²) to simulate the electrocoagulation process under different working conditions.

2. Data Collection

2.1 Set the laser pulse frequency to 200 Hz, the intensity of lasers A and B to 10 A, adjust the light guide arm so that the laser irradiation surface is parallel to the camera observation surface , and adjust the focal length so that the camera image is focused on the laser irradiation surface.

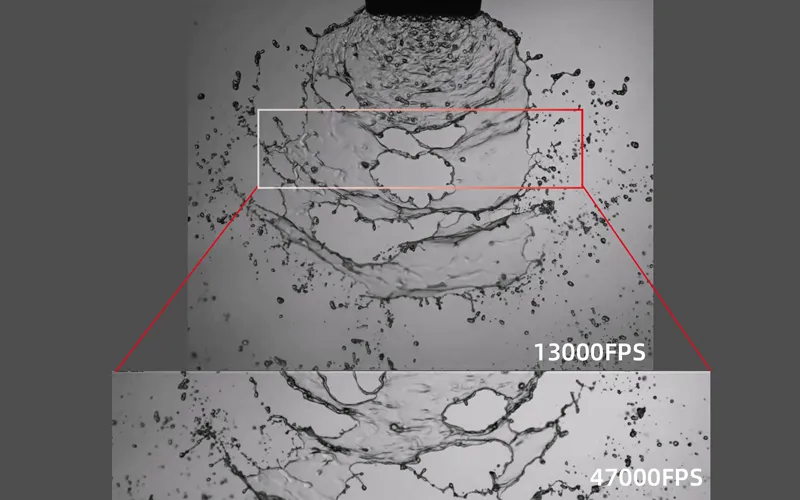

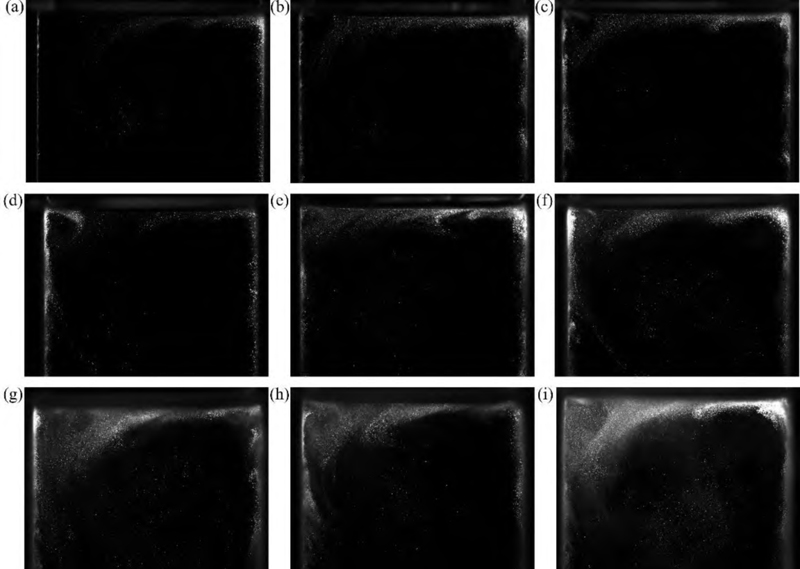

2.2 The PIV system was used to continuously observe the bubble movement under 9 different current densities, and a total of 5500 frames of image data were collected. The results showed that with the increase of current density, the bubble generation rate on the electrode surface increased, and the bubble distribution expanded from the surface layer of the solution to the deep layer, as shown in Figure 2 for details.

Figure 2 Bubble images at 9 current densities during electrolysis for 15 s

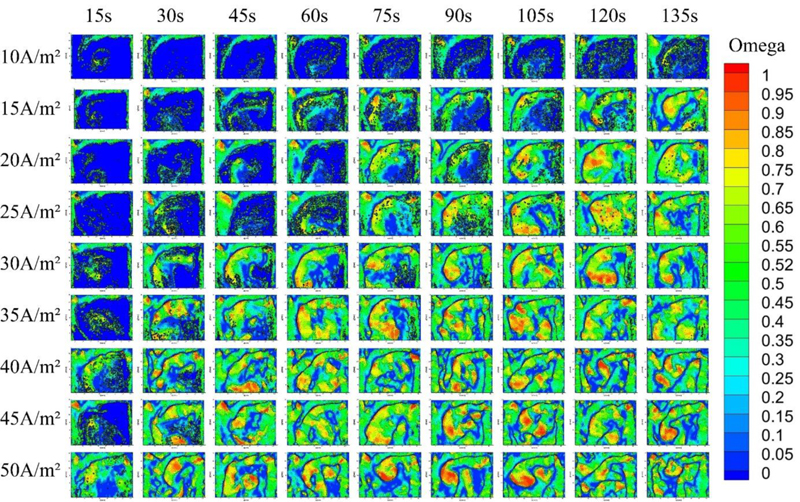

2.3 PIV flow field calculation and visualization research, based on the cross-correlation algorithm, the average displacement and velocity of particles in the window are calculated by fast Fourier transform FFT. The Revealer RFlow4 flow field measurement software is further used to calculate the vortex structure distribution in the flow field using the Omega criterion, identify the vortex boundary with Ω=0.52 , draw the vortex cloud map, and accurately quantify the number and intensity distribution of vortices, as shown in Figure 3.

Figure 3 Omega distribution cloud diagram under 9 groups of current density

Experimental conclusion

The experiment measured the changes in sediment particle size and solution turbidity under different current densities. When the current density was 40 A/m², D/V (the ratio of average particle size to average velocity) reached the maximum and the removal efficiency was the highest, indicating that floc formation and stability were optimal under this condition. Air flotation entrainment and flocculation sedimentation were the main factors affecting the reduction of turbidity, and the boundary particle size was 37.2 μm . Sediment particles smaller than this particle size were mainly removed by air flotation entrainment, and particles larger than this particle size were mainly removed by flocculation sedimentation.

The high-speed continuous observation capability and particle image processing capability of the Revealer PIV system provide strong support for in-depth research on the electro-flocculation process. By accurately capturing the original image of bubble movement and processing it to present the vorticity cloud map, it provides a scientific basis for optimizing the electro-flocculation effect, helps solve complex flow field problems, and promotes technological innovation in the fields of environmental protection and chemical industry.