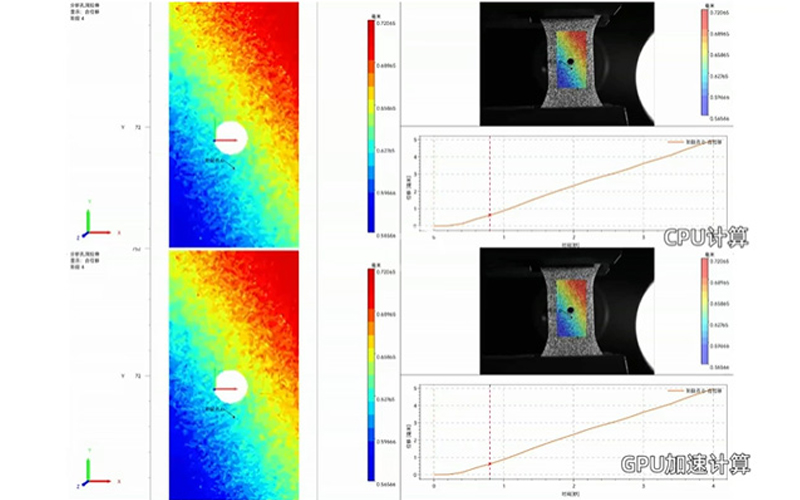

Observing the micro-scale, microsecond-level transient processes during the interaction between a cutting tool and a workpiece is crucial for tool development, as it helps establish the correlation between specific events—like vibration, chip clogging, or tool defects—and workpiece surface flaws, which is essential for optimizing cutting parameters and controlling machining quality.

Conventional High Speed Cameras are limited by temporal resolution and can only capture the general motion of the tool and workpiece, failing to resolve or track fine cutting jet features.

A tool laboratory utilized the Revealer NEO 25 Ultra High Speed Camera, provided by Agile Device, to observe the wood board cutting process.

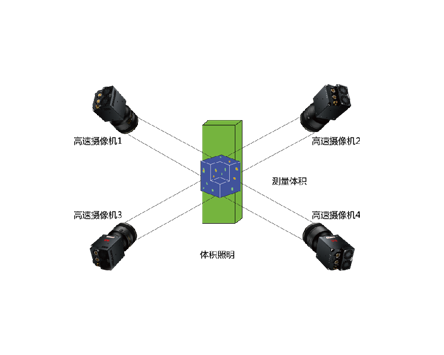

Core Equipment: Revealer High Speed Camera NEO 25.

Acquisition Rate: 25,000 fps.Resolution:1280×1024 at 25,000 fps, achieving a time resolution of 40 μs per frame.

Optics: Paired with an 18x magnification lens to observe details in a 1 cm×1 cm target area.

Lighting: Proprietary LED light source to ensure clear, blur-free high-speed images.

Experimental Objects: The workpiece was a hardwood substrate, and the cutting tool was a new four-flute milling cutter composed of four different shaped teeth.

The Revealer NEO 25 Ultra High Speed Camera captured the periodic high-speed cutting process of the four-flute milling cutter at an ultra-high frame rate of 25,000 fps. The microsecond-level sequence for key time points is analyzed below:

80 μs: The cutting edge first contacts the wood, causing fiber compression and initial stripping, but no stable chip formation.

320 μs:Wood fibers fracture in the primary shear zone, forming small chips that adhere to the rake face, marking the start of the cutting action.

~600 μs:The cutting depth reaches its peak and chip volume is maximized. As the tooth rotates further, the tooth gradually exits the contact zone.

~1320 μs:Driven by the centrifugal force from the tool's rotation, the chips move synchronously downward with the rake face.

2160 μs:Once the tooth disengages from the workpiece at a certain angle, the balance between centrifugal force, air resistance, and tool face friction is broken, and the powdery chips are ejected in a spray-like effect.

2200 μs:The second tooth enters the groove bottom already formed by the first tooth.

2440 μs:The leading edge of the second tooth starts generating new chips in the pre-damaged area. Since the cutting object is the irregular residual layer left by the first tooth, the chips are similar in form but finer than the first batch, indicating the second tooth's primary role is trimming.

3880 μs:The third tooth rotates to the contact area of the previous tooth. The wood in this region has been significantly removed by the first two teeth. Furthermore, the third tooth is designed for grinding, so the High Speed Camera captures very few chips.

5960 μs:The fourth tooth arrives, also producing no noticeable chips. This indicates the fourth tooth's role is to finish the surface left by the preceding teeth, achieving a polishing and fine finishing effect, which helps reduce defects like burrs.

7600 μs:The first tooth completes one full rotation and returns to the initial contact point, marking the end of a complete four-tooth cutting cycle.

7800 μs:The first tooth contacts the "new material" of the wood for the second time, generating new chips. The chip formation and exclusion dynamics repeat the first cutting's high-speed fluid-like fan-shaped ejection pattern, demonstrating stability and repeatability under high-speed cutting conditions.

This experiment successfully used the Revealer High Speed Camera NEO 25 to observe the micro-scale, high-speed dynamic interaction between the cutting tool teeth and the workpiece during wood machining.

Ultra High-Speed Photography: The technology can clearly capture the transient processes of tooth contact, compression, shear, and separation.

Material Removal Pattern: The four-flute milling cutter exhibits a material removal pattern where the first two teeth perform primary cutting, and the latter two teeth perform trimming/finishing at the same location.

Chip Ejection Dynamics: Chips captured by the High Speed Camera undergo a process of “initial formation→cutting→synchronous movement with the tooth→fan-shaped ejection”. This chip behavior is linked to the tooth structure design and is valuable for designing new tooling.