This experiment uses an ultra-high-speed imaging system together with stereo Digital Image Correlation (DIC) to directly measure the dynamic deformation of motor blades at 40,000 rpm. By quantitatively analyzing key metrics—including resultant displacement, inter-point distance change, out-of-plane vibration amplitude, and Lagrangian strain—the test verifies blade structural integrity and aerodynamic behavior under high-speed conditions. The measured data also supports motor power-output optimization and provides experimental evidence for simulation-model validation.

High-speed motors are widely used in thermal management modules and precision drive systems. Under high-speed rotation, the blades—being core components—are excited by centrifugal loads and aerodynamic loads, leading to elastic radial elongation, bending vibration, and strain variations. These responses can cause structural failure and degrade aerodynamic performance and efficiency.

Currently, blade deformation behavior under high-speed rotation is often predicted primarily through simulation models, but experimental validation data is insufficient, making it difficult to accurately represent real performance under complex operating conditions. Meanwhile, conventional high-speed cameras typically struggle to achieve both high temporal resolution and high spatial accuracy for quantitative measurements.

To address this gap, a domestic motor manufacturer introduced the Revealer stereo high-speed DIC system developed by Agile Device, combining Revealer NEO25 High-Speed Camera units with DIC to perform non-contact 3D full-field measurements of blade displacement, length change, out-of-plane vibration, and strain response under high-speed rotation. The objective is to validate simulation-model reliability using measured data.

2.1 Test Specimen

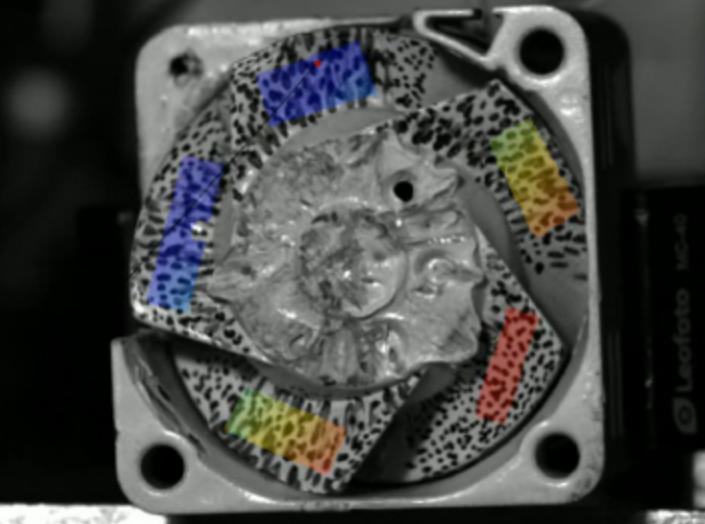

The specimen is a small high-speed motor blade with an outer diameter of approximately 4 cm. The motor is driven to 40,000 rpm.

2.2 Experimental Equipment

The experiment uses the Revealer stereo high-speed Digital Image Correlation (DIC) system, fully developed in-house by Agile Device. Key configuration:

High-speed cameras: Revealer NEO25 × 2 (stereo setup)

Acquisition settings: 41,000 fps under ROI mode

Recording duration: approx. 0.025 s

Lens: 100 mm fixed focal-length lens

Illumination: Revealer high-intensity continuous light source

Polarizers: polarizing filters mounted in front of the lenses to suppress strong specular reflection

2.3 Experimental Method

A stereo calibration procedure is performed first to establish the 3D measurement coordinate system. The stereo high-speed cameras then capture the speckle images of the rotating blade for about 0.025 s. Using the DIC algorithm, the 3D displacement and Lagrangian strain over time are obtained for selected tracking points (subset points) and a selected polygon ROI (subset region).

Considering the dominant rigid-body rotation in high-speed rotary motion, relative quantities—such as point-to-point distance change—are used to characterize blade length change, reducing the influence of global rigid motion on the deformation measurements.

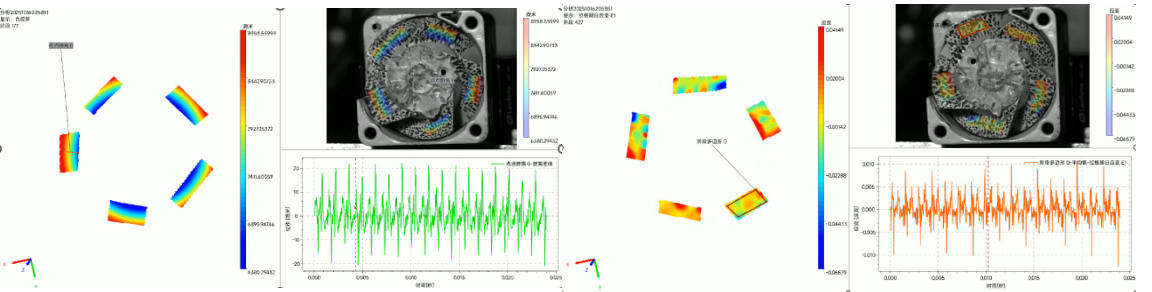

3.1 Resultant Displacement of a Selected Tracking Point

A tracking point on the blade is selected and its 3D resultant displacement during rotation is monitored. The high-speed DIC results show a clear periodic variation with an amplitude of approximately 32 mm. This displacement is primarily contributed by rigid-body rotation around the shaft axis and is mainly used to verify the completeness and stability of the DIC system in capturing motion trajectories under high-speed rotation.

3.2 Length Change Between Two Selected Points

Two tracking points are selected on the same blade. The time-history of their point-to-point distance change is computed to characterize radial tensile deformation driven by centrifugal loading. For miniature high-speed motors, the safety clearance between blade and casing is a critical design parameter to prevent rubbing or even failure during operation. Therefore, measuring the centrifugal elongation of the blade under high-speed conditions is a key objective of this test.

Results show that the fluctuation amplitude of the inter-point distance difference falls within 20–30 μm, consistent with simulation predictions. This indicates that at 40,000 rpm steady-state operation, the blade’s centrifugal elongation remains within the elastic regime and the structure maintains adequate length margin. From a design perspective, this measured elongation provides direct experimental guidance for determining the blade-to-casing radial clearance, helping reduce rubbing risk and improving overall reliability and service life.

3.3 Out-of-Plane Vibration Amplitude at a Selected Point

The out-of-plane displacement (perpendicular to the rotation plane) of a selected tracking point is analyzed. DIC measurements show that the vibration amplitude is generally controlled within 2 mm, indicating no significant out-of-plane resonance or unstable vibration under the current speed and operating conditions. Overall rotor dynamics remain stable.

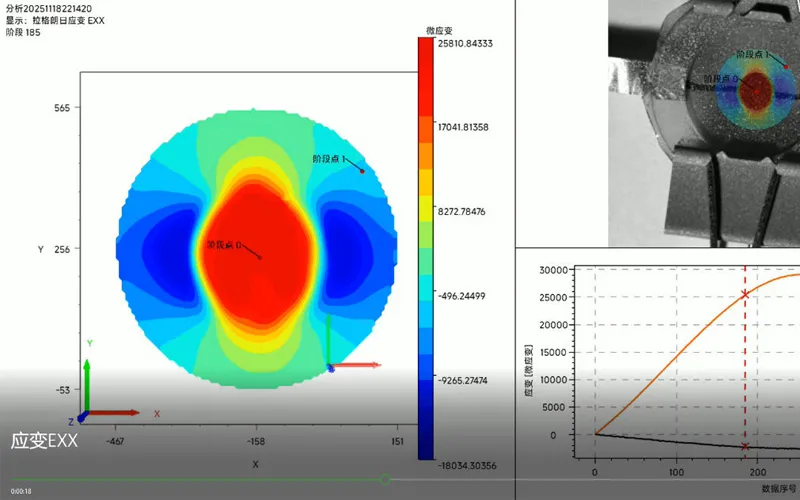

3.4 Lagrangian Strain in a Selected Region

A region on the blade surface is selected, and the time-series Lagrangian strain is computed using the Revealer DIC software. The results show the average Lagrangian strain fluctuates within approximately 10 με (microstrain), suggesting the blade material remains in a low-strain elastic state with sufficient structural safety margin. From the strain perspective, the measurements also support the reasonableness of the simulation model’s material parameters and load settings.

4.1

This experiment achieved non-contact 3D full-field dynamic displacement and strain measurement of a small motor blade under 40,000 rpm high-speed rotation, verifying the applicability of stereo high-speed DIC under extreme operating conditions. Compared with relying solely on simulation, high-speed DIC provides direct quantitative experimental evidence for motor performance evaluation, helping shorten design verification cycles and reduce safety risks.

4.2

Measured results show that the blade’s axial/radial length-change magnitude is 20–30 μm, consistent with simulation results, indicating the centrifugal deformation in steady high-speed operation is controllable and does not adversely affect aerodynamic performance or structural safety. Out-of-plane vibration and Lagrangian strain show no instability, confirming smooth dynamic response during start-up and steady operation and demonstrating high reliability of the design solution.

4.3

For equipment selection, the Revealer NEO25 High-Speed Camera combined with a speckle pattern and stereo DIC workflow can achieve micrometer-level accuracy for dynamic deformation measurement of high-speed rotating structures. It is well-suited for engineering validation of small high-speed motors, micro-rotors, and similar rotating components.