The combustion process involves a variety of chemical reactions, and the concentration distribution of the key intermediate product CH2O (formaldehyde) can reflect the combustion efficiency. It is of great significance for optimizing the combustion process, improving combustion efficiency and reducing pollution.

Traditional invasive measurement technology will interfere with the combustion flame field, and has a slow response speed and low accuracy. The planar laser induced fluorescence, or PLIF technology, has the characteristics of high temporal and spatial resolution, non-contact, and multi-component selection, and can achieve high-precision measurement of CH2O concentration in the combustion flame.

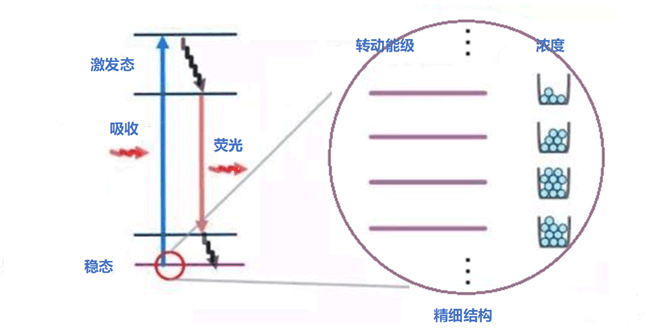

PLIF technology is based on the interaction between laser and matter. When a beam of planar laser of a specific wavelength is irradiated on the target molecules (such as CH2O) in the combustion flame, these molecules absorb the laser energy and transition from the ground state to the excited state. The molecules in the excited state will spontaneously return to the ground state in a short time and emit fluorescence. The fluorescence signal is collected by a high-speed camera or sCMOS scientific camera, and the CH2O concentration distribution image in the combustion flame is obtained based on the relationship between the fluorescence intensity and the molecular concentration.

Figure 1 Schematic diagram of PLIF technology

The main components of the PLIF experimental system of Revealer are:

1) Pump laser, frequency 30Hz, energy 180mJ, used to generate 355nm wavelength planar laser to excite CH2O molecules in the flame.

2) Revealer G_Pro series high-speed camera, used to capture flame fluorescence images.

3) P43 phosphor screen image intensifier, used to enhance the fluorescence signal generated by the formaldehyde molecules when excited.

4) Revealer synchronization controller, minimum pulse width 1ns, time synchronization accuracy 1ns, used for precise synchronization of laser pulses, high-speed cameras, and image intensifiers.

5) Optical components, high-reflection mirrors, concave lenses, convex lenses, filters, etc., used to focus the laser into a thin sheet, and collect and filter the fluorescence signal to improve the signal-to-noise ratio.

6) Flame generator, used to generate a stable combustion flame.

Figure 2 Schematic diagram of PLIF system

Step 1: System calibration

The measurement area is filled with three concentrations of CH2O: 0 mg/m3, 0.03 mg/m3, and 0.05 mg/m3. Fluorescence images at corresponding concentrations are collected to establish a fluorescence intensity-concentration relationship curve.

Step 2: Data acquisition

Revealer high-speed camera is used with an image intensifier and a bandpass filter to capture the fluorescence image generated after CH2O molecules are excited.

Step 3: Data post-processing

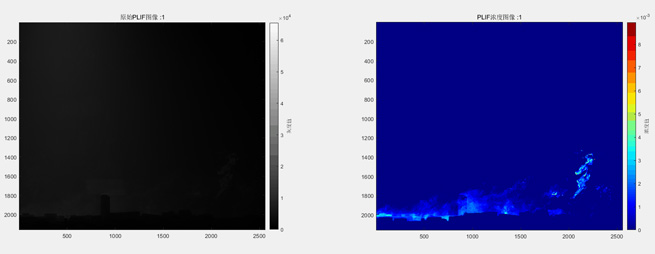

Based on the calibrated fluorescence intensity-concentration curve, the grayscale data of the original fluorescence image is converted into pseudo-color data representing the concentration, that is, the concentration distribution image. By analyzing the sequence images captured by the high-speed camera, the variation pattern of CH2O concentration over time and space is obtained. The pseudo-color image shows that the concentration is higher in the flame front area and lower in the flame tail area.

Figure 3 Pseudo-color animation of component concentration

As an advanced optical diagnostic technology, the PLIF measurement method can provide high-temporal and spatial resolution images of CH2O concentration distribution in combustion flames, helping researchers understand the chemical reaction mechanism in the combustion process and providing experimental data support for improving combustion efficiency and reducing pollutant emissions.

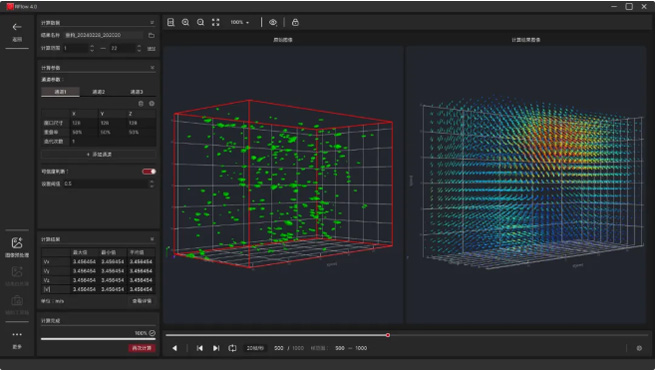

PLIF planar laser induction technology can also be combined with PIV particle image velocimetry technology, which has important applications in turbulence research, chemical engineering, environmental monitoring and other fields.

Self-developed PIV measurement software, suitable for 2D2C, 2D3C, 3D3C, PLIF, PTV, bubble measurement and other application scenarios.

Autonomous and controllable PIV high-speed camera, PIV ultra-clear camera