Original by Revealer

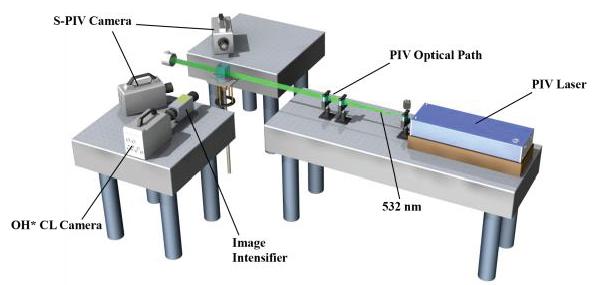

Stereo PIV is an advanced optical diagnostic technique that extends standard 2D PIV by using two cameras to capture the third velocity component ($W$) within a light sheet. By viewing the laser-illuminated particles from two different angles, a Stereo PIV system can reconstruct the full 3D velocity vector field ($\text{U, V, W}$), making it indispensable for complex flows like the stratified swirl flames analyzed in this study.

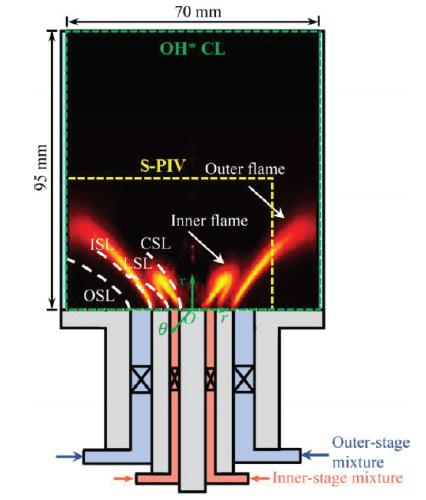

Diagnostics: Combined Stereo PIV and OH* Chemiluminescence.

System Speed: Multi-kilohertz frame rates using Revealer S-Series.

Key Finding: Identified x/D ≈ 0.2 as the critical zone for flame stability.

Application: Optimization of low-emission stratified swirl burners.

Stratified swirl combustion is widely adopted in modern low-emission and high-efficiency combustor design. However, as operating conditions approach the Lean Blowout (LBO) limit, the flow field becomes highly unstable. Small perturbations can trigger localized quenching or complete flame extinction, threatening combustion stability and engine safety.

To investigate these critical dynamics, researchers employed high-frequency OH* chemiluminescence (CL) and Stereo Particle Image Velocimetry (Stereo PIV)—powered by Agile Device and the Revealer High Speed Camera—to visualize the transient behavior of premixed methane–air stratified swirl flames under near-LBO conditions.

This study provides key insight for optimizing advanced combustion systems and improving LBO margin.

2.1 Equipment Configuration

Stratified Swirl Burner

A dual-stage concentric swirl injector was used, consisting of:

Inner Stage: 6-blade axial swirler

Outer Stage: 18-blade axial swirler

Lip Region: 5 mm separation structure generating a Lip Recirculation Zone (LRZ)

Multiple shear layers formed: OSL, ISL, LSL, and CSL

This architecture creates a complex recirculation topology essential for flame stabilization.

Stereo Particle Image Velocimetry (Stereo PIV) System

Provided by Agile Device, featuring:

Dual-cavity Nd:YLF laser

The core of the system features two Revealer High Speed Cameras, which provide the high temporal resolution and pixel sensitivity required to resolve turbulent fluctuations in high-velocity flames.

Particle Image Velocimetry (PIV) software

Aluminum oxide (Al₂O₃) seeding particles

OH* Chemiluminescence (CL) System

One Revealer High Speed Camera with an image intensifier

UV lens + 308 nm bandpass filter

Synchronization Controller

Ensures temporal alignment between the Stereo PIV system and OH* CL diagnostics.

2.2 Operating Conditions

Five operating cases were designed: one non-reactive (NR) and four reacting cases (Case 1–4).

All cases maintained:

Velocity ratio VR = 0.2

Stratification ratio SR = 0.5

Equivalence ratio Ø decreased from 0.60 → 0.50, simulating progression toward LBO

Case | Ui (m/s) | Uo (m/s) | SR | Ø | Description |

NR | 5 | 1 | 0 | 0 | Non-reacting baseline |

Case 1 | 5 | 1 | 0.5 | 0.60 | Stable combustion far from LBO |

Case 2 | 5 | 1 | 0.5 | 0.56 | Stable but closer to LBO |

Case 3 | 5 | 1 | 0.5 | 0.51 | Reversible near-LBO condition; periodic local quenching |

Case 4 | 5 | 1 | 0.5 | 0.50 | Irreversible LBO condition |

Ø = 0.50 was experimentally determined as the LBO threshold.

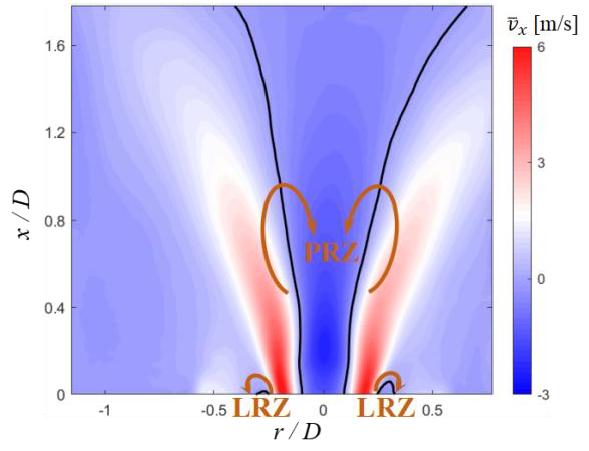

3.1 Non-Reactive Flow Field Structure

Using the Revealer Stereo PIV system, the cold-flow axial velocity field was measured (NR case). The dual-camera configuration allows for a comprehensive 3-component velocity field analysis, capturing not just axial and radial flow, but also the out-of-plane azimuthal components. This advanced 3D flow visualization reveals the intricate topology of the Primary Recirculation Zone (PRZ) that standard 2D PIV would otherwise compress or miss.

Key observations:

A Primary Recirculation Zone (PRZ) with a trumpet-shaped structure dominated the flow. Length: x/D ≈ 0.8

A compact Lip Recirculation Zone (LRZ) existed near the lip (x/D < 0.1)

This non-reacting baseline provides essential reference for identifying density-driven alterations in reacting cases.

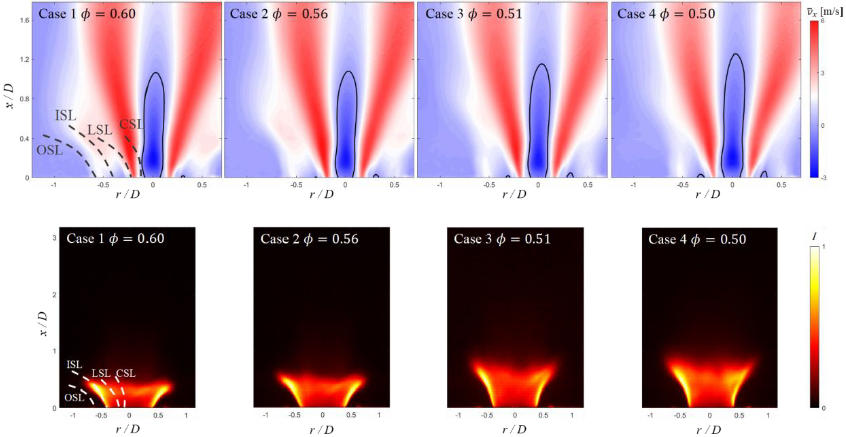

3.2 Evolution of Reacting Flow & Flame Structure

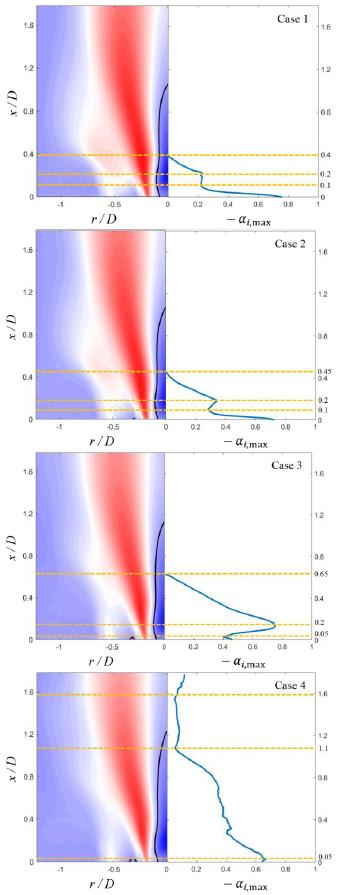

Time-averaged axial velocity and OH* CL intensity distributions for Case 1–4 show:

1). PRZ Lengthening Toward LBO

PRZ length increased from x/D = 1.0 (Case 1) to x/D = 1.2 (Case 4)

Indicates enlarged recirculation aiding—but also destabilizing—flame stabilization

2). Flame Lengthening

Flame length increased from x/D = 0.5 → 1.0 as Ø decreased

Caused by reduced laminar flame speed despite constant inlet velocity

3). Flame Anchoring Behavior

Flame primarily anchored along the Inner Shear Layer (ISL)

Outer-stage flame dominated the structure

Inner-stage flame remained unignited across all conditions

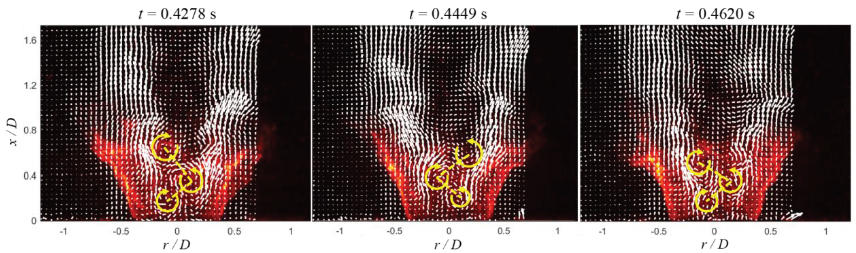

3.3 Transient Flow–Flame Interaction Near LBO

Case 3 (Reversible Near-LBO Condition)

High-speed 5 kHz Stereo PIV reveals:

A Precessing Vortex Core (PVC) spiraling downstream along the CSL

PVC does not directly impinge on the flame front

This intermittently triggers local quenching followed by re-ignition, confirming reversibility

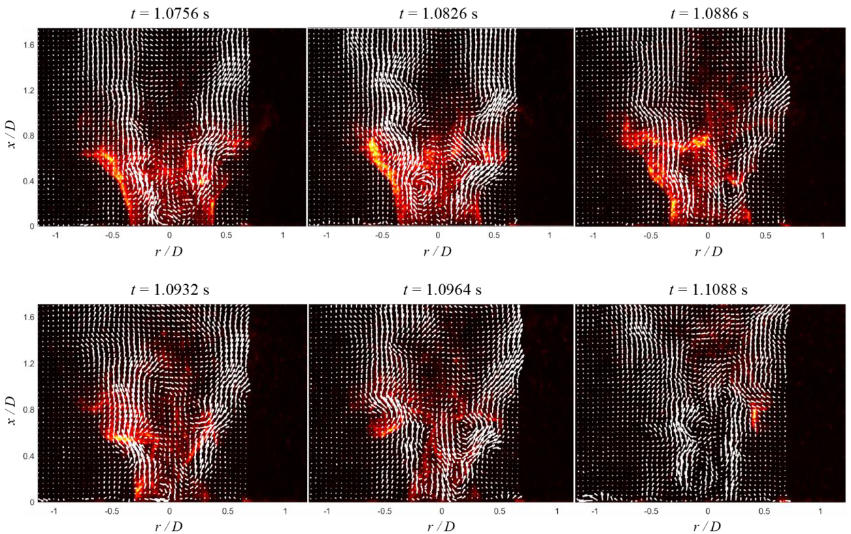

Case 4 (Irreversible LBO Condition)

Transient OH* CL + PIV sequences over ~0.0332 s show:

t = 1.0826 s: First major flame hole appears

t = 1.0886–1.0964 s: Quenching zone expands upstream along ISL

t = 1.1088 s: Flame detaches from the lip → irreversible global extinction

3.4 Spatial Linear Stability Analysis (LSA) Using Stereo PIV Data

Applying LSA to the 3-D mean velocity field measured by the Stereo PIV system:

Case 1

Maximum PVC growth rate: 0.75 near the nozzle

Rapid decay at x/D = 0.2 where inner/outer jets merge

Indicates density-stratification-induced instability onset

Case 2

Maximum growth rate increases compared to Case 1

Suggests more pronounced local instabilities as Ø decreases

Case 3

Sharp growth-rate rise (0.4 → 0.75) in 0.1 < x/D < 0.2

Correlates with high-frequency local quenching

Case 4

PVC growth rate: 0.65 at x/D = 0.05

Remains nearly constant until x/D = 1.6

Eventually indicates global instability mode triggering irreversible LBO

Using the Agile Device Stereo PIV system, synchronized OH* CL imaging, and stability analysis:

I. PRZ extension and reduced equivalence ratio jointly drive enhanced flow instability as the system approaches LBO.

II. The PVC, although not directly interacting with the outer flame, induces local quenching through periodic flow disturbances in the jet-merging region.

III. LSA identifies x/D ≈ 0.2 as the most sensitive region for flame stability—a critical zone where combustor design should enhance fuel–air mixing or introduce stabilization features.

This study demonstrates the effectiveness of combining Revealer High Speed Camera technology, Agile Device Stereo Particle Image Velocimetry (PIV), and advanced diagnostics to resolve complex flow–flame dynamics in lean combustion environments.

Why are high-speed cameras essential for Stereo PIV in combustion?

Combustion events, particularly Lean Blowout (LBO) and turbulent flame propagation, occur in micro-second timescales. To resolve these transient vortex dynamics without motion blur, a camera must offer both high frame rates (kHz range) and a Global Shutter. The Revealer S1315, for instance, provides the necessary light sensitivity and synchronization precision to capture the displacement of seeding particles across two offset planes, which is the foundation of accurate 3D velocity vector reconstruction in Stereo PIV.

Can this Stereo PIV system be customized for different burner sizes?

Absolutely. As a specialized Stereo PIV system provider, Revealer understands that experimental volumes vary from micro-combustors to large-scale wind tunnels. We offer:

Customizable Synchronization: Precise temporal alignment between the dual-cavity laser and cameras.

Versatile Optics: A range of lenses from UV (for OH chemiluminescence)* to Infrared, ensuring the system fits your specific combustion chamber’s optical access.

Flexible Scheimpflug Mounts: Essential for maintaining focus across the tilted image planes inherent in Stereo PIV configurations.