3C electronic products are developing toward thinner, lighter, and higher screen-to-body ratio. As the core component for human-computer interaction, the drop resistance of display screens has become a key indicator of user experience. In a steel ball drop test of laptop screens conducted by a microelectronics factory, testers introduced the self-developed Revealer Digital Image Correlation (DIC) technology by HF Agile Device Co.,Ltd, combined with 10,000-frame high-speed cameras, to study the mechanical behavior of screen products under drop impact.

I. Use high-speed DIC equipment to capture the full-field displacement response of the screen under steel ball impact.

II. Identify the phased mechanical characteristics of screen deformation and the mechanism of energy dissipation.

3.1 Experimental Setup

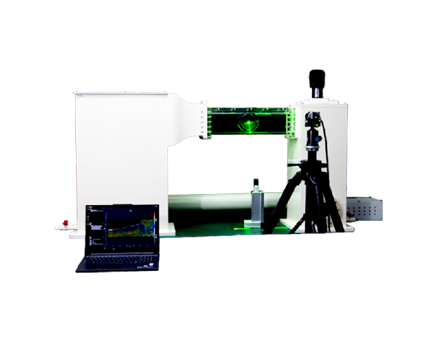

The test object is a display module of a certain model of laptop. The impact method involves a steel ball freely falling from a predetermined height to impact the central area of the screen. The high-speed DIC equipment consists of two high-speed cameras (Model S1315) that form a binocular stereo vision system to capture transient images during the drop process. Digital Image Correlation (DIC) software is used for strain analysis, and a blue light source is equipped to enhance the contrast of surface speckles.

3.2 Experimental Procedures

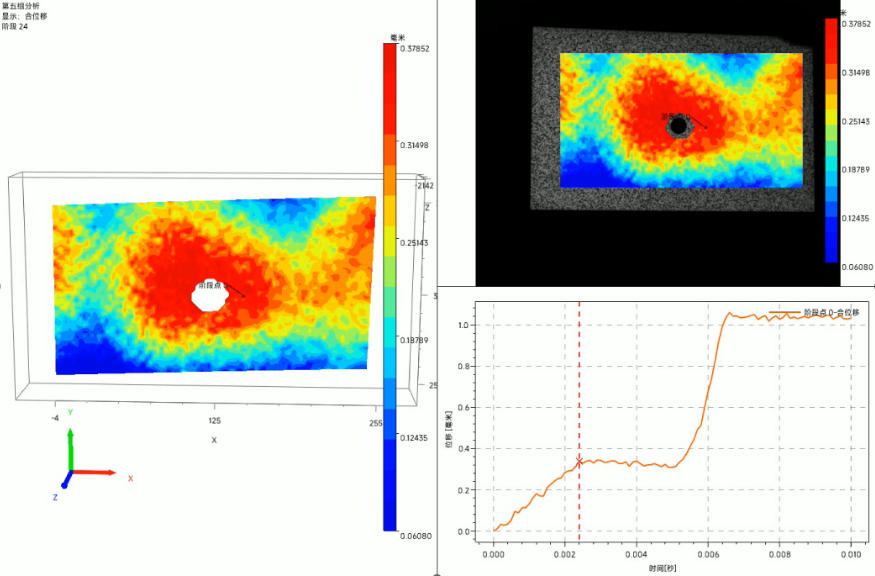

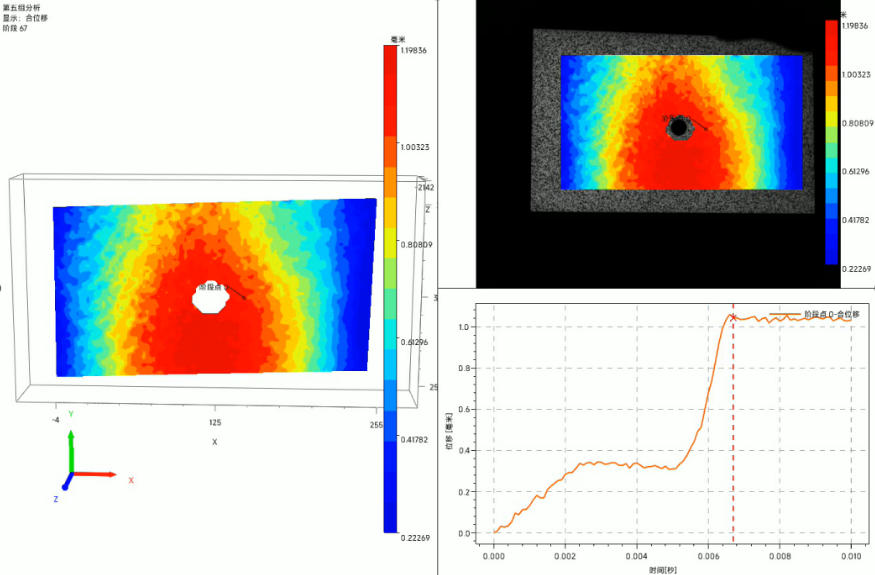

The Revealer high-speed DIC equipment successfully captured the time-series images of the full-field displacement evolution of the screen within 10 ms after the steel ball impact. Based on the deformation morphology, wavefront propagation characteristics, and dynamic response trends, three key time nodes were identified: 2.4 ms, 5.0 ms, and 6.8 ms.

I. t = 0~2.4 ms: Initial Energy Input Phase

At the moment the steel ball impacts the screen, a local depression is rapidly formed in the impact point area, creating an obvious annular ripple. This ripple spreads quickly around the impact point as the center. At 2.4 ms, the first deformation peak is reached, with the resultant displacement of the phase points near the impact point reaching 0.32 mm. This phase is dominated by local compression and elastic deformation; the impact energy is concentrated near the impact point, and global vibration has not yet been triggered.

II. t = 2.4~5.0 ms: Rapid Energy Propagation Phase

After 2.4 ms, the annular ripple continues to propagate radially outward, and the amplitude of the ripple gradually decreases—indicating that the stress wave inside the screen material gradually attenuates during propagation. Meanwhile, the displacement gradient in the upper-left corner of the screen is steeper than that in the lower-right corner, suggesting differences in the local stiffness of the screen material. Energy diffuses gradiently from the center to the surroundings, and the corner areas begin to bear bending stress. A portion of the impact energy is converted into structural vibration energy.

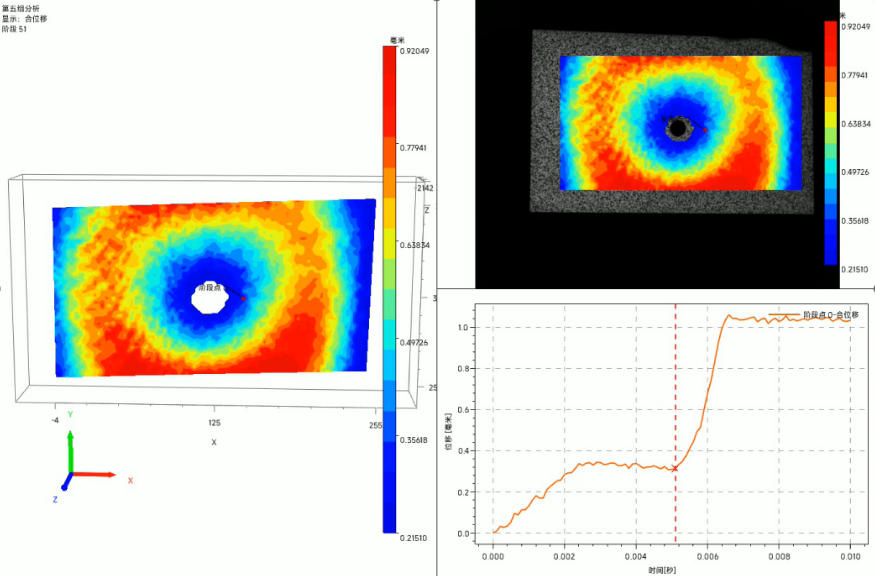

III. t = 5.0~6.8 ms: Energy Rebound and Redistribution Phase

After 5.0 ms, under the superposition effect of reflected waves and incident waves, local energy concentration occurs. The maximum resultant displacement of the phase points near the impact point reaches a peak of 1.4 mm, and the deformation morphology transitions from "gradient undulation" to "central depression".

IV. t = 6.8~10 ms: Energy Dissipation Phase

After 6.8 ms, the screen enters the free vibration phase. The displacement of the phase points near the impact point oscillates in the range of 1.1~1.4 mm, with no obvious secondary deformation—indicating that the impact energy has been gradually dissipated through material damping and structural vibration.

In this experiment, the Revealer high-speed DIC equipment provided by HF Agile Device Co.,Ltd completely captured the dynamic response process of the laptop screen within 10 ms during the steel ball drop test. Based on the time-series analysis of displacement contour maps, the evolution of the displacement field in 4 typical deformation phases (energy input, energy transfer, energy rebound, and energy dissipation) was analyzed in detail.

The experiment found that the impact response of the screen exhibits obvious phased structural response characteristics. Each phase corresponds to different states of energy transfer and dissipation, which are affected by material damping and structural boundary conditions. These findings help engineers identify the optimization direction for screen materials.