In aircraft engine design, rotating blades are susceptible to excitation frequency at high speeds, leading to resonance, fatigue, and even failure. Therefore, identifying blade modal parameters (such as natural frequencies and mode shapes) at specific rotational speeds helps engineers determine the safe speed range and prevent blade failure.

Revealer engineers used digital image correlation (DIC) technology to measure the vibration modes of the blades at three predicted rotational speeds. These measurements were compared with the simulated third-order modal natural frequencies of 700 Hz, 1400 Hz, and 3000 Hz to verify the accuracy of the simulation model.

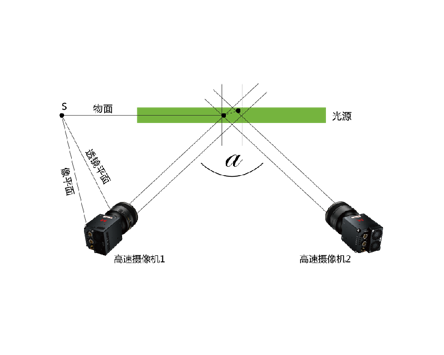

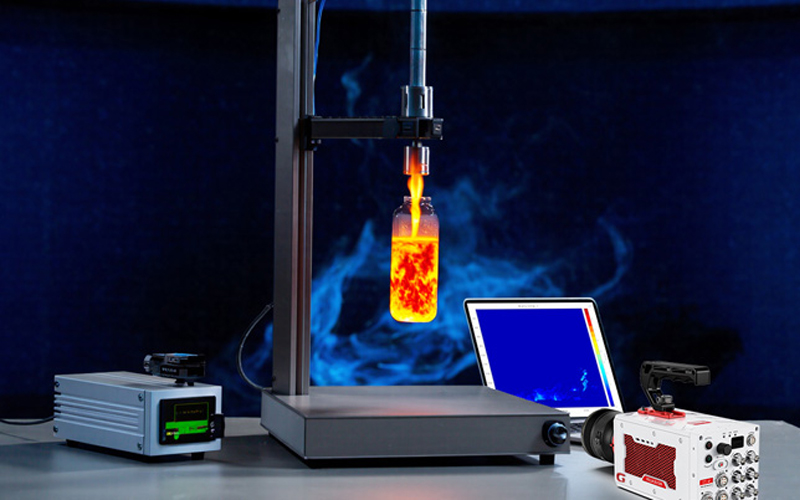

The experiment utilized a domestically produced, advanced ultra-high-speed digital image correlation (DIC) system. It consisted of two Revealer NEO 25 high-speed cameras with a resolution of 1280 × 1024 and a frame rate of 25,000 fps, paired with polarizing filters to capture dynamic images of the blades and eliminate reflections. A matte pen was used to create speckle patterns on the blade surface. RDIC software was used for modal analysis.

1. A matte pen was used to create a 5 mm uniform speckle pattern.

2. Based on the resonance points predicted by the simulation model, three operating speeds were designed: 3250 rpm, 6114 rpm, and 6400 rpm. Two high-speed NEO 25 cameras were used to capture 69,000 frames of video images from the bottom up.

Figure1

3. Data analysis was performed using the Cross Power Spectral Density (CPSD) algorithm. By calculating the cross power spectrum between the reference measurement point and other measurement points, the blade's frequency response characteristics under excitation were extracted, and rigid body rotational displacement was eliminated to ensure accurate modal analysis results.

First-Order Modal Analysis

The first-order mode reflects the blade's foundational stiffness characteristics and represents the blade's most prone low-frequency resonance. The first-order mode corresponds to a speed of 3250 rpm, with a measured natural frequency of 708 Hz, a 1.1% error from the simulated model's 700 Hz (Figure 2). This mode exhibits a low-frequency response, and at a relatively low speed, the excitation frequency easily excites the natural frequency. This helps engineers identify the safe speed range and avoid prolonged operation near 3250 rpm to prevent blade fatigue failure. The modal characteristics demonstrate overall blade bending vibration, with the amplitude decreasing from the blade root to the tip and a uniform distribution (Figure 3).

Figure2

Figure3

Second-Order Modal Analysis

Second-order modal analysis reveals the complex deformation modes of the blade at medium and high speeds. At 6114 rpm, the measured natural frequency is 1425 Hz, with a 1.8% error from the simulated model's 1400 Hz (Figure 4). The modal characteristics indicate torsional vibration, with the node located in the middle of the blade and a symmetrical torsional amplitude distribution (Figure 5). Second-order modal measurements reveal the risk of torsional resonance at medium speeds, helping engineers optimize engine control systems to avoid operation in high-stress zones. Furthermore, the torsional modal shapes pinpoint weaknesses in the blade under torsional loads, guiding improvements to blade geometry.

Figure4

Figure5

Third-order modal analysis

Third-order modal analysis reveals the risk of microcracks or acoustic fatigue in high-frequency blade resonance. At 6400 rpm, the measured natural frequency was 2951 Hz, with a 1.6% error from the simulated model's 3000 Hz (Figure 6). The modal characteristics indicate high-frequency, localized vibrations. However, due to interference from ambient noise such as airflow and bearing vibration, the reconstruction of the modal shape is incomplete. Only localized peak responses were observed at blade 1, such as the tip and edge (Figure 7). The amplitudes were small and unevenly distributed, prompting engineers to increase inspections of localized hotspot failure areas.

Figure6

Figure7

Experimental Verification: Using an ultra-high-speed digital image correlation (DIC) system, we were able to obtain vibration modal data for high-speed rotating aircraft engine blades at different speeds. The measured natural frequencies of each modal order were within 1.8% of the simulated error, effectively validating the simulation model and providing an experimental basis for studying blade vibration characteristics and designing speed avoidance strategies to prevent resonance.

Modal Characteristics: The first-order mode exhibits a typical bending shape, the second-order mode exhibits a torsional shape, and the third-order mode exhibits localized vibration. The modal shape evolves from global to localized. Due to the influence of ambient noise, the response amplitude of the third-order mode is small, and the reconstructed modal shape is incomplete. Revealer engineers will subsequently refine the noise filtering algorithm to improve the high-frequency signal-to-noise ratio to further verify the reliability of the simulation model in the high-frequency range.