1. Technical Background

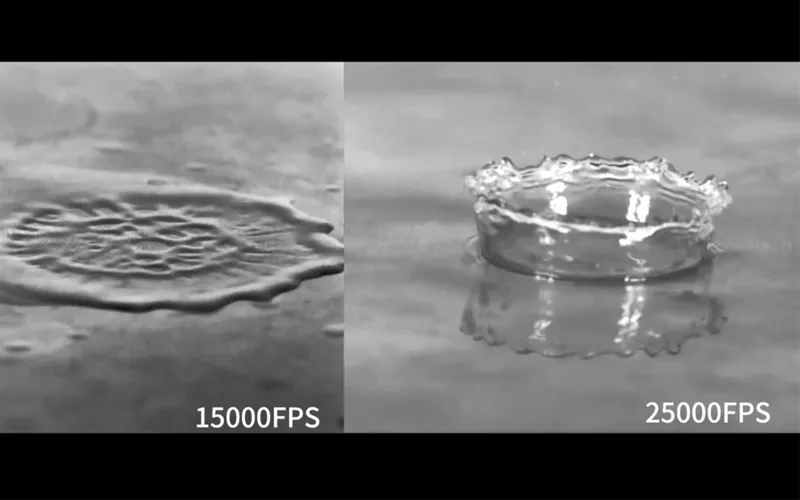

Digital Image Correlation (DIC) is a key technology for studying the mechanical properties of materials and analyzing the strain of complex structures in the fields of materials science, aerospace, civil engineering , etc. Global DIC is widely used in complex working conditions (such as crack propagation and deformation of composite materials) because of its advantage of providing continuous deformation information of the entire field . However, global DIC has high computational complexity, and the single-core calculation of the CPU takes a long time, which leads to efficiency bottlenecks.

2. Principle of the method

Global DIC is a technology that analyzes the displacement and strain fields of the entire field by matching the entire image as a whole. Compared with local DIC, global DIC can provide continuous deformation information and is suitable for scenes such as large displacement, complex strain, and cracks. In global DIC calculations, the image is divided into multiple sub-areas, each of which corresponds to a finite element node. The number of these sub-areas may reach hundreds of thousands or even more . The parallel computing capability of the GPU enables the calculation of all sub-areas to be performed simultaneously, greatly shortening the processing time. The specific acceleration steps are as follows:

1) Data preprocessing: input image data and sub-area grid position information into the GPU.

2) Parallel computing: the GPU core processes the finite element node data of each sub-area simultaneously.

3) Result output: return the calculation results to the host to generate the full-field displacement field and strain field.

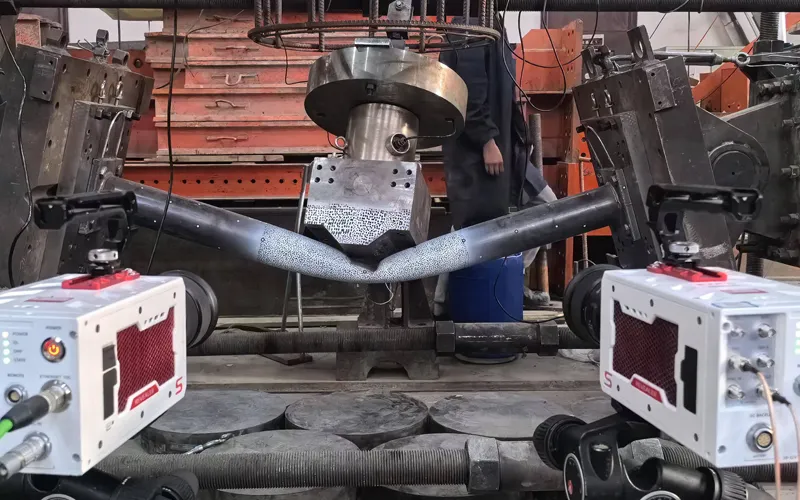

3. Experimental verification

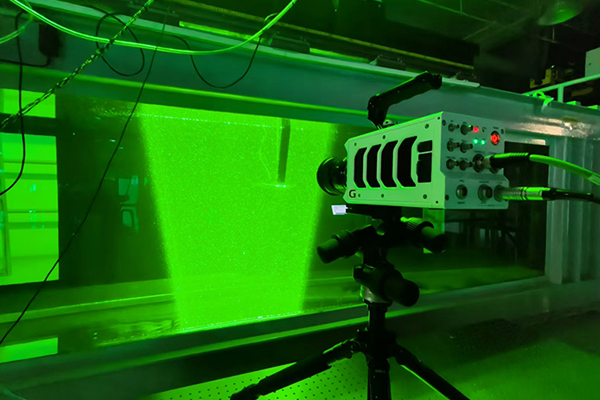

To verify the actual effect of GPU-accelerated global DIC, Qianyanlang engineers designed four sets of experiments based on the comparison between NVIDIA RTX 4070 GPU and i7-13790F CPU, covering four typical scenarios:

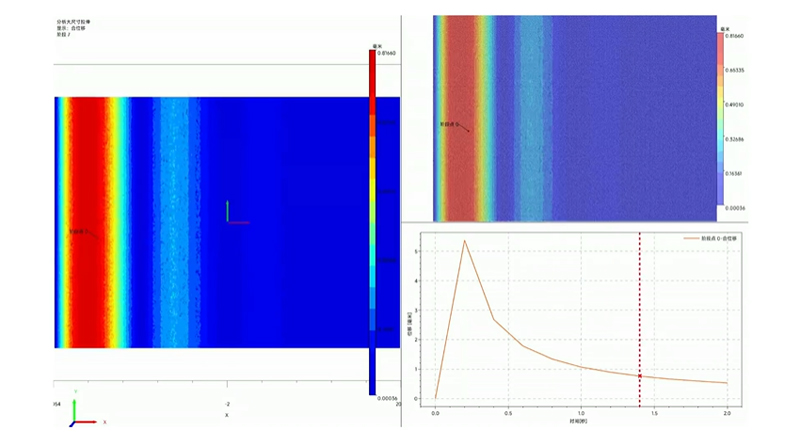

Scene 1 Simulation-Large Image Stretching

Data scale: 489,982 calculation points for step size 5, 122,700 calculation points for step size 10, and 54,600 calculation points for step size 15.

Calculation results: The CPU cannot complete the calculation of step lengths 5 and 10. The GPU speeds up 101 times more than HKUST when the step length is 15.

CPU calculation time | GPU calculation time | Speedup | |

Step 5 - Calculation points 489982 | Unable to calculate | 46.43 | / |

Step 10 - Calculation points 122700 | Unable to calculate | 14.02 | / |

Step 15 - Calculation points 54600 | 905.27 | 8.88 | 101 |

Scene 2: Stretching with holes

Data scale: 36430 calculation points for step size 5, 9211 calculation points for step size 10, and 4124 calculation points for step size 15.

Calculation results: The GPU acceleration ratios are 44.6 times, 35 times, and 30 times respectively, significantly improving the computing efficiency.

CPU calculation time | GPU calculation time | Speedup | |

Step 5 - Calculation points 36430 | 618.192 | 13.837 | 44.6 |

Step 10 - Calculation points 9211 | 289.526 | 8.274 | 35 |

Step 15 - Calculation points 4124 | 216.471 | 7.192 | 30 |

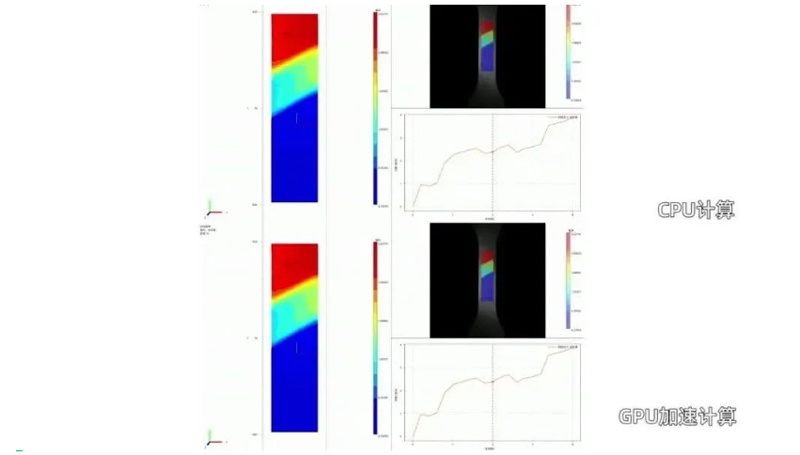

Scenario 3 Material stretching

Data scale: 8055 calculation points for step size 5, 2070 calculation points for step size 10, and 900 calculation points for step size 15.

Calculation results: The GPU acceleration ratios are 22.2 times, 12.8 times, and 12 times respectively, and the calculation time is greatly shortened.

CPU calculation time | GPU calculation time | Speedup | |

Step 5 - Calculation points 8055 | 113.559 | 5.117 | 22.2 |

Step 10 - Calculation points 2070 | 46.979 | 3.669 | 12.8 |

Step 15 - Calculation points 900 | 33.944 | 2.823 | 12 |

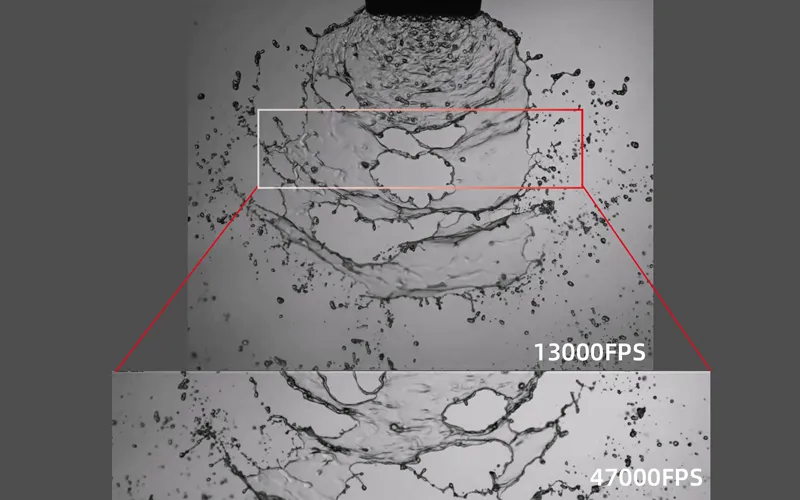

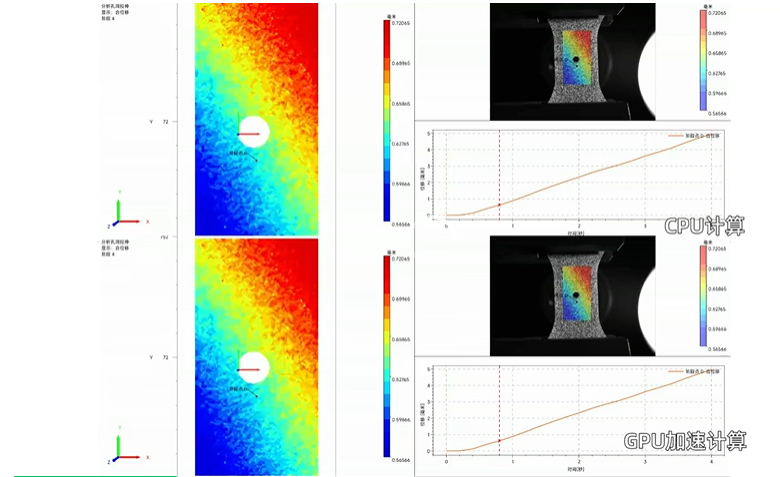

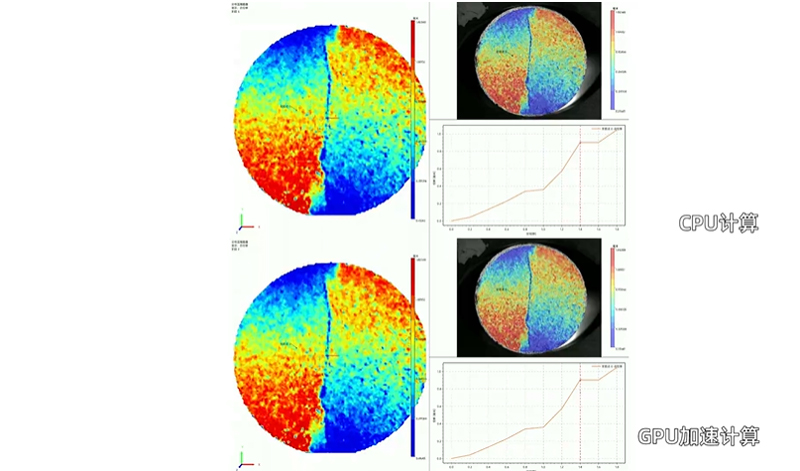

Scene 4: Squeezing the disc

Data scale: 12403 calculation points for step 5, 3102 calculation points for step 10, and 1371 calculation points for step 15. Calculation results: GPU acceleration ratios are 47 times, 63.9 times, and 76.5 times, respectively, showing excellent acceleration performance.

CPU calculation time | GPU calculation time | Speedup | |

Step 5 - Calculation points 8055 | 95.807 | 2.028 | 47 |

Step 10 - Calculation points 2070 | 58.344 | 0.913 | 63.9 |

Step 15 - Calculation points 900 | 58.717 | 0.767 | 76.5 |

4. Experimental conclusions

Through four sets of experimental comparisons, it is found that compared with traditional CPU, GPU acceleration method has greatly improved in accuracy, efficiency and applicability.

1) Accuracy: The comparison of strain cloud graphs shows that the results after GPU acceleration are consistent with the results calculated by CPU, ensuring data accuracy.

2) Efficiency: GPU-accelerated global DIC calculations are 10 to 70 times faster than CPUs, significantly reducing processing time .

3) Applicability: GPU acceleration can be completed efficiently for both simulation data and real-shot data.

5. Technology Outlook

GPU acceleration of global DIC technology breakthroughs not only solves the efficiency bottleneck of traditional computing methods, but also brings new breakthroughs in the fields of materials science, aerospace, and civil engineering. GPU acceleration can be applied to:

Real-time monitoring: Real-time monitoring of material deformation on industrial production lines to optimize process flow.

Complex structure analysis: Efficient analysis of complex scenarios such as crack propagation and composite material strain.

High-precision research: Supports full-field measurement of high-resolution images, providing more accurate data support for scientific research.

GPU-accelerated global DIC technology is expanding the efficiency boundary of digital image correlation DIC. Qianyanlang engineers will continue to iterate and evolve to inject new vitality into scientific research and engineering practice.