In the manufacturing of new energy vehicle drive motors, the quality of power module pin welding impacts the product's electrical performance and mechanical stability.

In traditional welding processes, arc discharge durations are measured in microseconds and accompanied by intense arc flash, making it difficult for process technicians to accurately determine the arc's actual position and shape using conventional inspection equipment. Arc position deviation and uneven heat input can easily lead to defects such as cold welds and spatter.

Process engineers at a precision motor manufacturer employed the Revealer high-sensitivity ultra-high-speed camera NEO 25, capturing images at 110,000 frames per second at a resolution of 260,000 pixels. This allows for microsecond-level analysis of the entire arc discharge evolution process, revealing the intrinsic correlation between energy distribution characteristics in micro-regions at the pin contact interface and weld deformation.

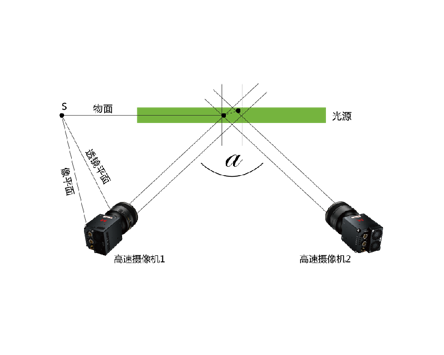

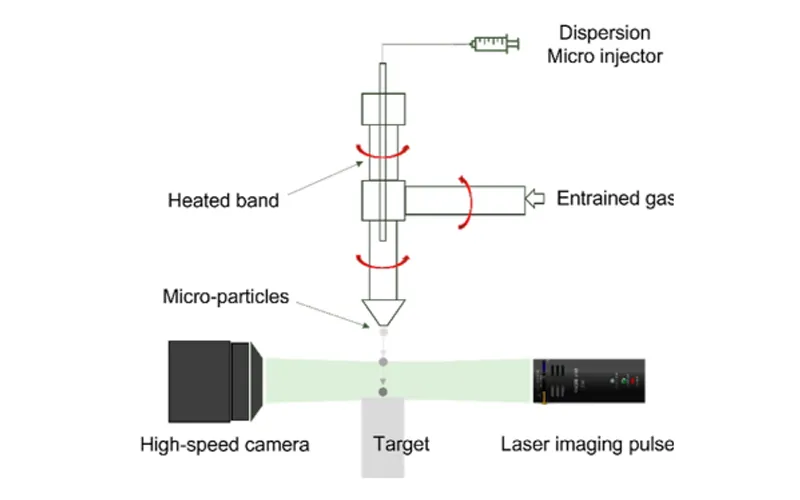

The experimental subject was a metal pin of a power module, with a diameter of 10 mm, a field of view of 100 mm × 100 mm, and a working distance of 15 cm. A Revealer high-sensitivity ultra-high-speed camera NEO 25 was used, with ROI cropping and a frame rate of up to 110,000 fps. Intelligent image triggering was used to lock onto the discharge moment and capture high-frame-rate image data. By analyzing slices of the captured video sequence, the following dynamic characteristics of the arc discharge were observed:

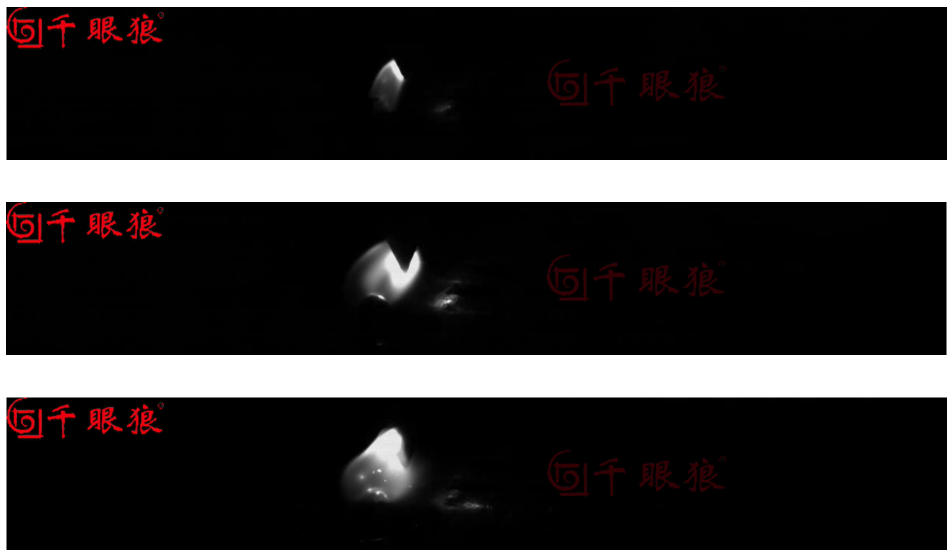

Arc initialization phase (0-0.2 ms): When the welding current passes through the pin gap, the extremely high electric field intensity ionizes the gas molecules around the pin, releasing free electrons and ions. The free electrons further collide with gas molecules, triggering a chain ionization reaction. The gas is instantly converted to a plasma state, forming a bright plasma column, but the plasma column is small and concentrated near the pin tip (Figures 1-3).

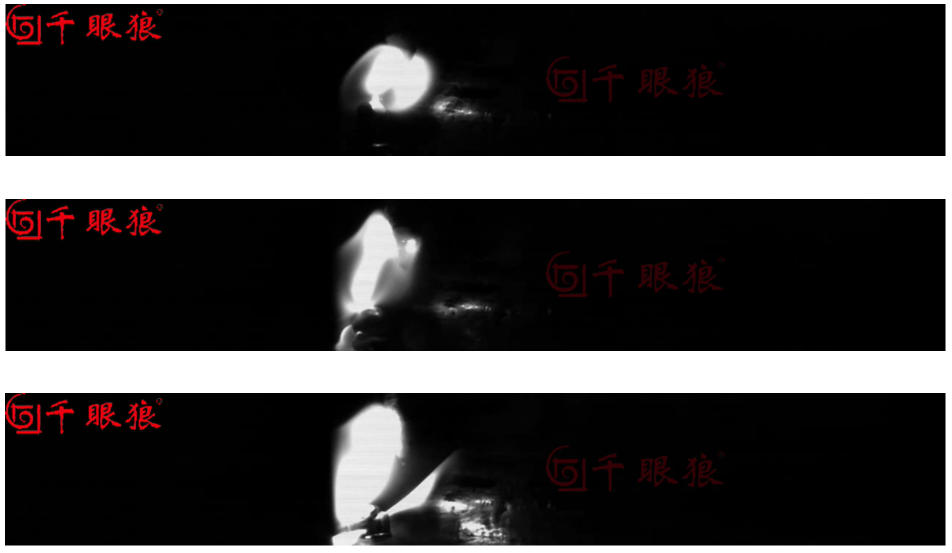

Stable combustion phase (0.2-0.8ms): With continued energy input, the plasma column rapidly expands outward, evolving from an elongated shape to a spherical or mushroom-like shape. Influenced by electromagnetic forces, thermal collisions, and other factors, the energy distribution within the plasma column becomes uneven, leading to directional migration of ions and electrons, further exacerbating the column's morphological fluctuations and diffusion (Figures 4-6).

Decay and extinction stage (0.8~1.2ms): As the welding current gradually decreases, the energy of the plasma column decreases, the internal ion and electron recombination reaction rate accelerates, and some areas return to a neutral gas state. Under the action of surface tension and gas resistance, the plasma column gradually shrinks toward the electrode gap and gradually disappears, and the welding process ends (Figures 7~9).

In this experiment, the Revealer high-sensitivity ultra-high-speed camera NEO 25 meticulously captured the arc discharge process during pin welding, quantifying the arc's temporal and spatial distribution characteristics and instabilities. This provides a visual basis for improving welding quality and advancing precision motor manufacturing processes.

Appendix: Core Features of the Revealer high-sensitivity ultra-high-speed camera NEO 25↓↓↓