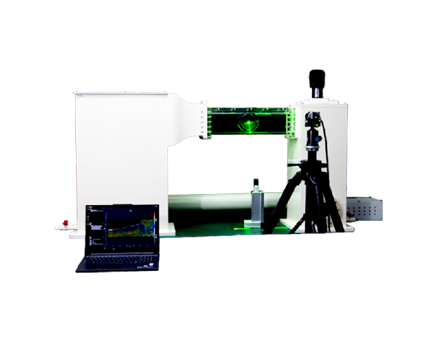

— Introduction to the Revealer RVM Digital Image Correlation System

In the fields of material testing and structural testing, Digital Image Correlation (DIC) has become a widely adopted non-contact technique for full-field displacement and strain measurement. As experimental scenarios increasingly involve dynamic loading conditions such as impact, vibration, and fatigue, conventional offline DIC workflows show limitations in real-time feedback and engineering applicability.

To address these challenges, Agile Device has developed a new-generation Revealer Digital Image Correlation (DIC) software, RVM. Through a system-level redesign of computational architecture, algorithmic workflow, and user interaction, RVM enables real-time DIC measurement tailored for engineering and research applications.

Traditional DIC software typically relies on an offline “acquire-then-process” workflow, where experimental parameters and analysis results can only be validated after data acquisition, limiting in-situ experimental control.

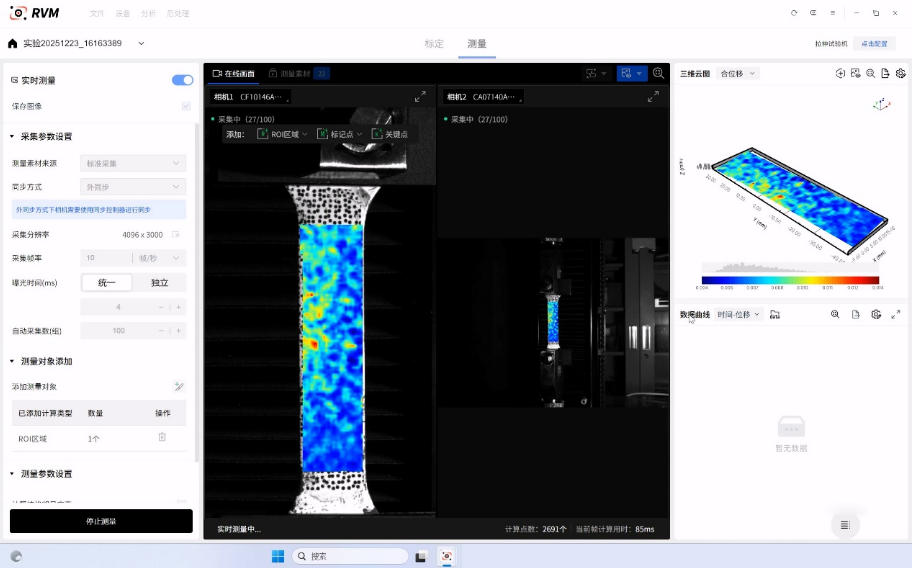

The Revealer RVM Digital Image Correlation (DIC) software introduces high-order image interpolation algorithms and a high-performance parallel computing framework, enabling real-time full-field DIC analysis, including:

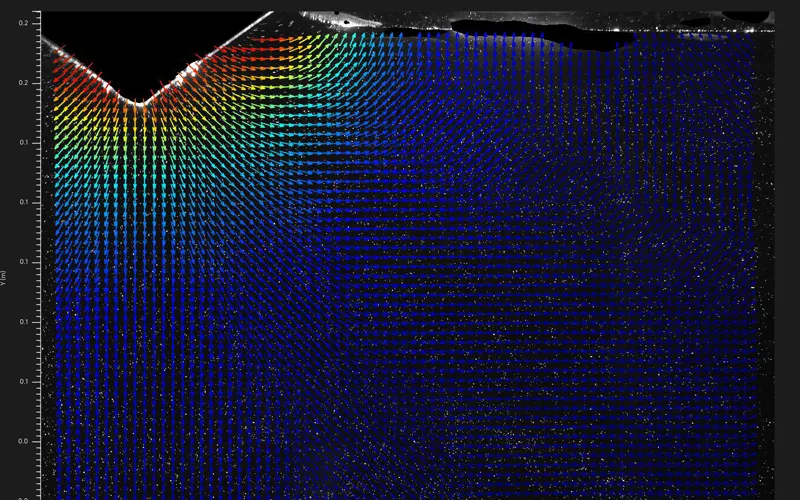

Real-time full-field displacement and strain computation

Real-time video extensometry

Real-time feature point and marker tracking

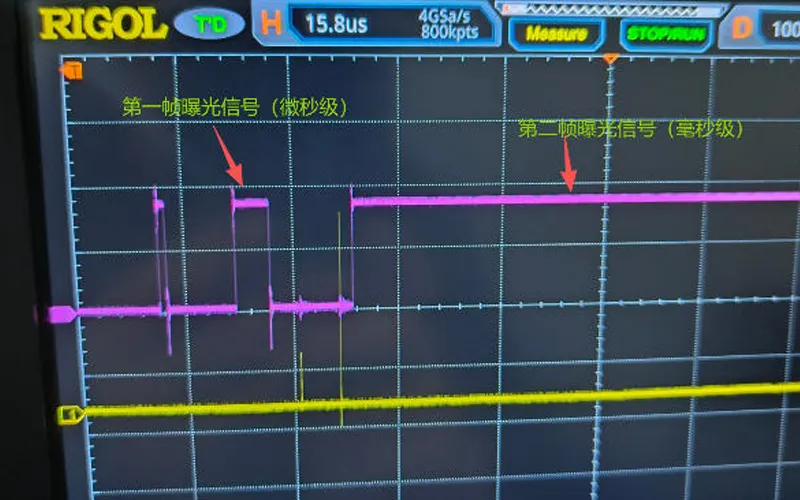

Under a resolution of 4096 × 3000 pixels, RVM supports real-time computation of over 10,000 measurement points, achieving strain calculation rates of up to 20 fps. This capability allows researchers to observe strain localization and crack initiation during dynamic experiments, reducing information loss associated with offline processing.

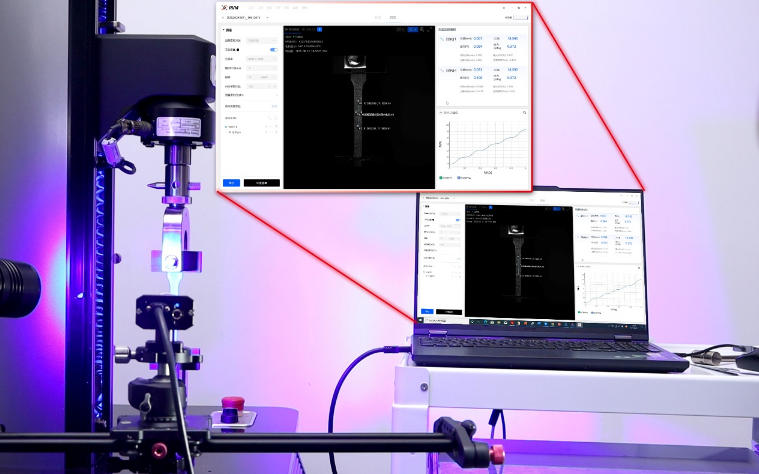

In tensile and large-deformation tests, contact extensometers often suffer from installation complexity and detachment risks. The Revealer RVM DIC software implements a real-time video extensometer based on sub-pixel feature tracking and dynamic gauge length compensation.

This function provides real-time output of axial strain, transverse strain, and Poisson’s ratio at frame rates of several hundred frames per second, making it suitable for elastomers, rubber, composite materials, and fiber-based specimens.

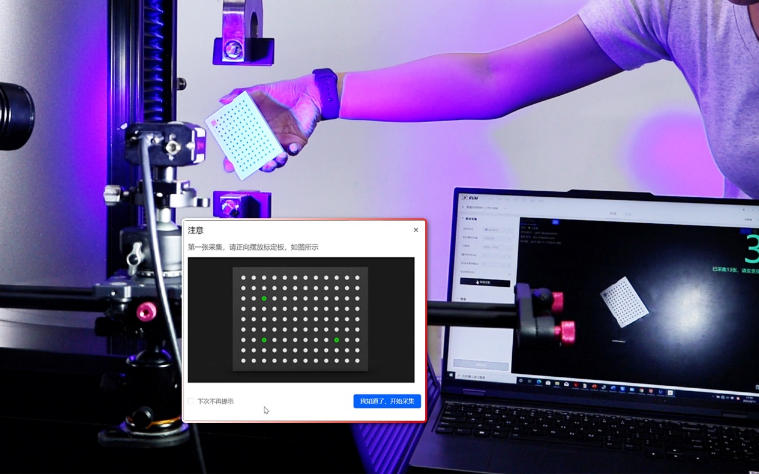

Calibration accuracy is critical to the reliability of Digital Image Correlation measurements. Conventional DIC systems require substantial user expertise to ensure appropriate calibration quality.

The Revealer RVM Digital Image Correlation software incorporates an intelligent calibration mechanism through coordinated hardware and software design. The system automatically evaluates calibration board pose and coverage during acquisition and provides real-time adjustment guidance, improving calibration consistency in both laboratory and field environments.

At the software architecture level, RVM redesigns the traditional DIC workflow to enhance continuity and usability:

Guided project configuration

Real-time visualization of raw images, strain maps, and extensometer curves

Embedded operational guidance

Multi-format data export compatible with MATLAB and Python

Furthermore, the Revealer RVM Digital Image Correlation (DIC) software provides standard communication interfaces and SDKs, enabling integration with infrared cameras, testing machines, and other sensors for multimodal measurement systems.

The Revealer RVM Digital Image Correlation (DIC) software represents a transition of DIC technology from a precision-focused analysis tool to a real-time, intelligent engineering measurement platform. Its system-level innovations in real-time computation, intelligent calibration, and workflow optimization offer an efficient and reliable solution for material mechanics research, structural health monitoring, and industrial inspection.

Q1: What is the Revealer Digital Image Correlation (DIC) software?

A:

The Revealer Digital Image Correlation (DIC) software is a non-contact full-field measurement software developed by Agile Device for research and engineering applications. It is used to measure displacement and strain fields of materials and structures during mechanical loading. The latest-generation product, Revealer RVM, supports real-time Digital Image Correlation analysis and is suitable for dynamic and complex experimental conditions.

Q2: What are the main differences between Revealer RVM and conventional DIC software?

A:

Compared with conventional offline Digital Image Correlation (DIC) software, Revealer RVM is characterized by its real-time computation capability, intelligent calibration mechanism, and engineering-oriented workflow design. These features enable real-time output of full-field strain, video extensometry data, and displacement information during experiments.

Q3: Does the Revealer Digital Image Correlation (DIC) software support real-time strain measurement?

A:

Yes. The Revealer Digital Image Correlation (DIC) software RVM supports real-time full-field strain measurement. Under high-resolution imaging conditions, the software is capable of stable real-time strain computation across a large number of measurement points, making it suitable for impact, vibration, and fatigue experiments.

Q4: What research and engineering applications is the Revealer DIC software suitable for?

A:

The Revealer Digital Image Correlation (DIC) software is widely applicable to material mechanical property testing, structural health monitoring, composite material research, large-deformation testing of elastomers and rubber materials, as well as various industrial inspection scenarios.

Q5: Does Revealer RVM support integration with other testing equipment?

A:

The Revealer Digital Image Correlation (DIC) software RVM provides standard communication interfaces and software development kits (SDKs), enabling integration with testing machines, infrared cameras, and other sensors for the construction of multimodal coupled measurement systems.