Deep-sea risers are core components of marine oil and gas transportation and seabed observation systems. Long-term erosion by ocean currents will induce vortex-induced vibration (VIV), which will cause fatigue damage and fracture of the riser structure, threatening operational safety. Traditional strain gauges or accelerometers can only obtain local point data and cannot fully characterize the full-field dynamic response of the riser under complex modes.

Recently, Revealer technical engineers and researchers from an engineering laboratory jointly conducted a non-contact measurement of the riser vortex-induced vibration modal experiment based on DIC technology.

1) Capture the full-field displacement distribution and high-order vibration mode evolution law of the riser at different flow rates.

2) Quantify the strain concentration area when the vibration mode switches and evaluate the life of the riser.

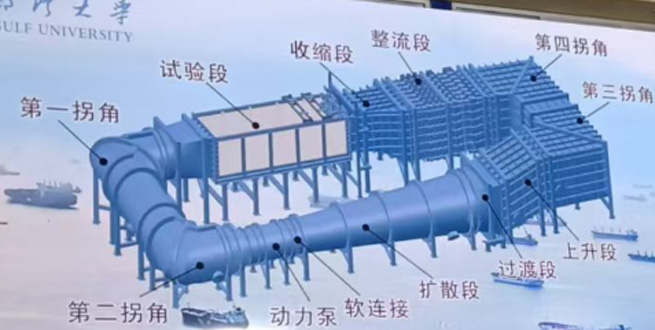

1) The main body size of the water tank: 28m×10m×4.5m.

2) Flexible riser, length 1.5 meters.

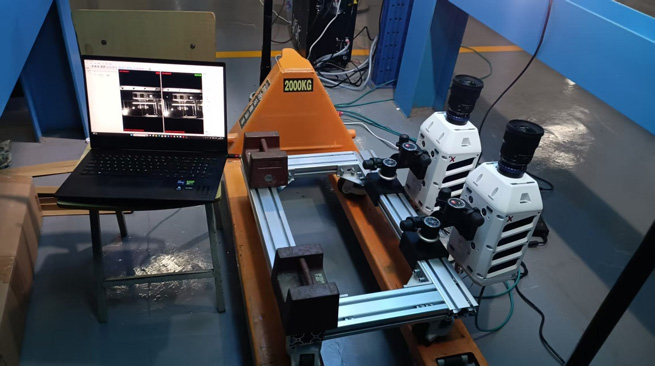

3) Revealer DIC binocular high-speed measurement device, consisting of 2 high-speed cameras (2560×1920 @2000fps), a high-power 300W light source, a synchronous controller, and DIC three-dimensional strain measurement software.

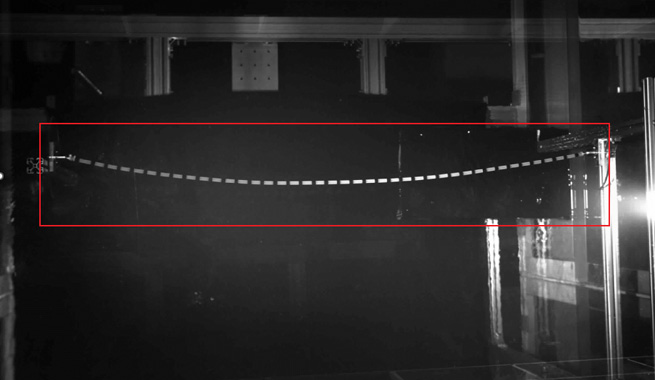

The first step is to build a Revealer DIC binocular high-speed measurement device, covering a 2m*1.6m field of view, as shown in the figure.

Step 2: Spray high-contrast speckle on the surface of the flexible riser.

Step 3: Fix the flexible riser in the middle of the water tank, start the water tank, increase the motor speed evenly and continuously, and adjust the water flow rate to 2m/s per second.

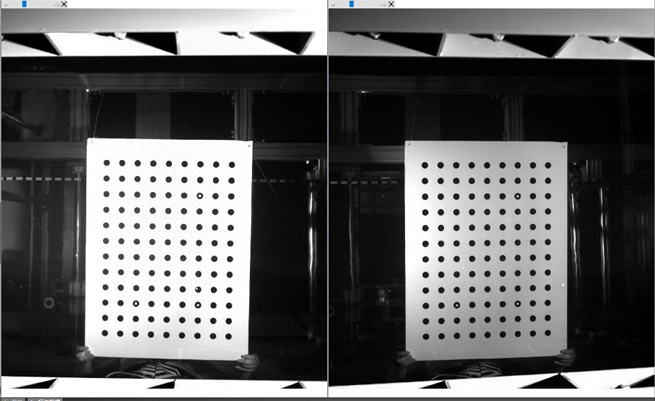

Step 4: Adjust the camera angle to 20°, adjust the lens focus ring, adjust the light source angle to make the image clear, place the 80mm point spacing calibration plate in the water, and perform 24-step standard calibration. Correct image distortion and determine the spatial position relationship.

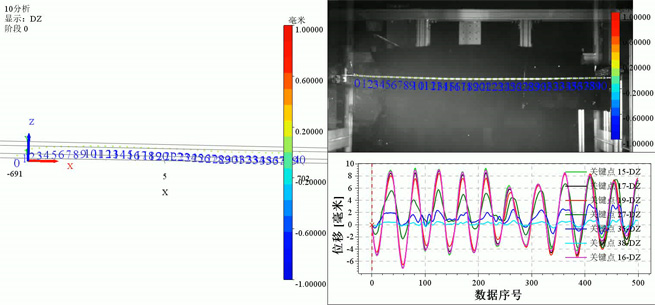

Step 5: Use the Revealer high-speed camera to collect the original image of the riser's swinging state in the water flow, and use the DIC three-dimensional strain measurement software to calculate the displacement values DX/DY/DZ of the riser in three directions (Video 1), and call the modal analysis module to analyze the mode of the riser (Video 2).

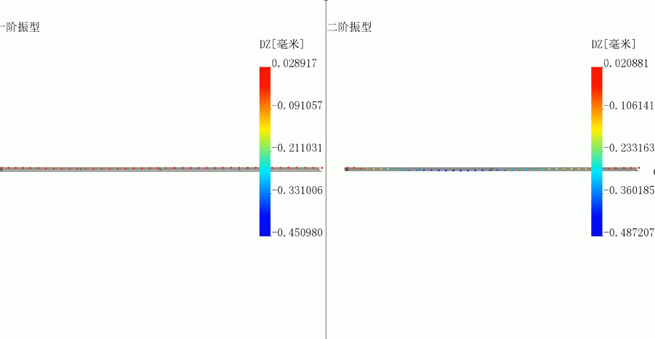

The experimental results show that there are differences in the displacement and strain distribution of the riser under different vibration modes. Under the first-order vibration mode, the displacement and strain of the riser are mainly concentrated in the middle area, and increase with the increase of vibration frequency; under the second-order vibration mode, the displacement and strain distribution of the riser show obvious nodes and antinodes, and the strain value reaches the maximum value at the antinode, indicating that the stress on the riser under the second-order vibration mode is more concentrated and uneven, and fatigue damage is prone to occur.

The experiment proves that the Thousand Eye Wolf Revealer DIC binocular high-speed strain measurement system can accurately measure the displacement and stress distribution of the riser under different vibration modes, providing technical support for scientific researchers to explore more effective vibration reduction measures.

Revealer Optical Image Measurement Laboratory is one of the key research and development bases built by the China Science and Technology Vision Reference Metrology Institute and the domestic key university laboratory. It covers an area of about 200 square meters and currently has a full-time optical measurement team of more than 20 people, including 7 doctors. It provides comprehensive, visual, and system-level solutions based on high-speed photography technology and digital image related technology. It provides 20kN seated and 5kN desktop universal testing machines, video extensometers, high-speed cameras, high-resolution cameras, high-precision displacement detection optical platforms, laser interferometers and other instruments and equipment to visualize the stress-strain behavior, elastic modulus, stretching, Poisson's ratio, crack extension characteristics, etc. of various types of materials such as metals, composites, and elastic-plastic materials under dynamic, static, and thermal loads.

Revealer Optical Image Measurement Laboratory is open to teachers from universities, research institutes, and technical personnel from enterprises and institutions. Please make an appointment for communication.