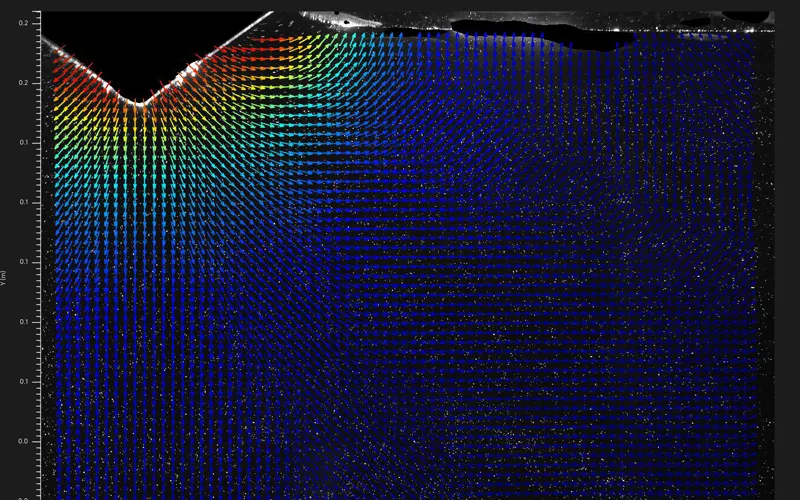

In the evolving landscape of material science, capturing transient deformation in real-time is a critical challenge. Agile Device has pioneered a breakthrough in Digital Image Correlation (DIC) technology, transitioning from traditional "post-processing" models to millisecond-level real-time feedback. By integrating the Revealer High Speed Camera with high-order sampling algorithms, this system enables synchronized monitoring of displacement and strain fields during dynamic loading.

Digital Image Correlation (DIC) is a non-contact, full-field optical technique used to measure material deformation by tracking speckle patterns on a specimen's surface. While standard DIC often requires offline analysis, the solution developed by Agile Device engineers utilizes high-performance computing architectures to achieve:

Instantaneous Feedback: Displacement and strain data are calculated and visualized as the experiment occurs.

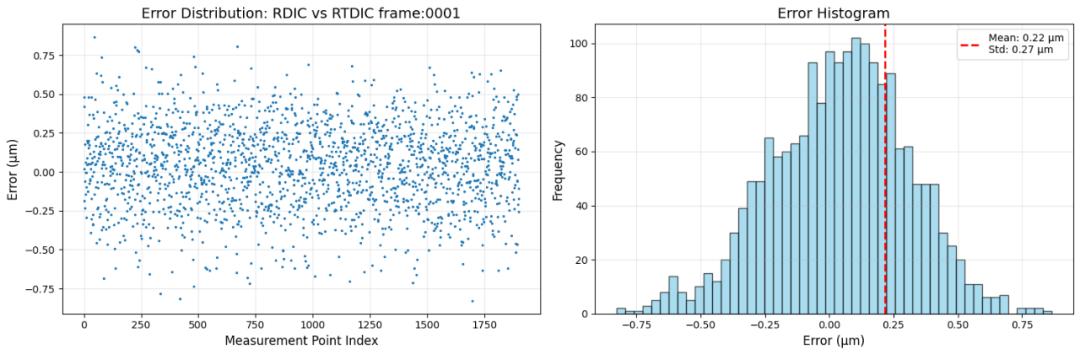

High Precision: Sub-pixel measurement accuracy through Bicubic B-spline interpolation.

Dynamic Compatibility: Seamless integration with a Revealer High Speed Camera to capture high-velocity mechanical events.

The core value of the Agile Device real-time DIC system lies in the balance between computational speed and measurement precision.

Local Displacement Solving

The algorithm tracks the speckle pattern before and after loading. By minimizing the grayscale difference between the reference and deformed image subsets, the system identifies the integer pixel displacement (u, v)

High-Order Grayscale Interpolation

To achieve sub-pixel accuracy necessary for mechanical analysis, Agile Device employs a Bicubic B-spline interpolation method. This ensures a continuous grayscale surface, allowing the Digital Image Correlation (DIC) software to resolve minute deformations that occur between individual pixels.

The hardware backbone of any dynamic DIC setup is the imaging sensor. Agile Device recommends the Revealer High Speed Camera (such as the S1310M or S200 models) for several reasons

High Frame Rates: Essential for capturing transient strain in impact or tensile tests.

Low Image Noise: High-quality sensors ensure the stability of the speckle pattern, which is crucial for the Digital Image Correlation (DIC) algorithm's correlation coefficient.

Global Shutter: Eliminates motion blur, ensuring that every frame captured by the High Speed Camera represents a precise moment in the material’s deformation history.

Through CPU parallel acceleration and optimized memory management, Agile Device has achieved industry-leading processing speeds.

Resolution (Pixels) | Calculation Points | Subset Size | Step Size | Average Frame Rate (FPS) |

2448 × 2048 | 10,070 | 21 px | 5 px | 20 |

4096 × 3000 | 5,000 | 25 px | 7 px | 45 |

The real-time Digital Image Correlation (DIC) technology from Agile Device is currently transforming several sectors:

Aerospace: Monitoring structural integrity during high-speed vibration and thermal stress tests.

Automotive Safety: Analyzing crash test deformation in real-time using multiple High Speed Camera setups.

Closed-Loop Control: Utilizing DIC strain feedback to control testing machines dynamically, ensuring specimens remain within specific strain limits.

By bridging the gap between high-speed image acquisition and real-time data processing, Agile Device and its Revealer brand of High Speed Camera solutions are setting a new standard for Digital Image Correlation (DIC). This technology not only enhances experimental efficiency but also opens the door to online quality monitoring and advanced structural health diagnostics.