Mobile phone drop tests are conducted to evaluate whether mobile phones can maintain structural integrity and normal functionality when accidentally dropped. As consumers' demands for mobile phone durability increase, the accurate quantification of mechanical and kinematic parameters during the drop process has become a crucial part of product R&D and quality assessment.

The 6D measuring instrument provided by HF Agile Device Co.,Ltd, by combining a high-resolution high-speed camera with a high-precision pose calculation algorithm, realizes image acquisition throughout the entire process of simulating a mobile phone drop to impact and real-time dynamic measurement of 6Dof parameters. It provides data support for mobile phone structural design and anti-drop performance optimization.

I. Verify the feasibility and accuracy of the 6D measuring instrument in measuring attitude angles during mobile phone drop tests.

II. Obtain the 6D motion parameters of the mobile phone throughout the drop process.

III. Analyze the variation law of the mobile phone's impact angle under different initial attitudes when it touches the ground.

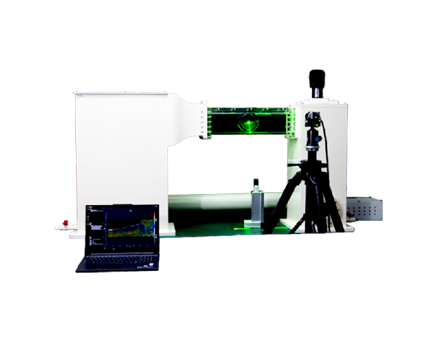

The experiment adopted the Revealer 6D measuring instrument developed by HF Agile Device Co.,Ltd, which includes a high-resolution high-speed camera (2560×2016 @2000fps), 6Dof measurement software, cooperative targets with circular coding (affixed to the surface of the measured object and automatically identified by the 6Dof measurement software), and a mobile phone model with the same shape and weight as the real phone.

In the experiment, the mobile phone model was freely released from a height of 0.5m to simulate the drop process (see Figure 1). The high-speed camera was triggered synchronously to capture image sequences, and the 6Dof software automatically identified the targets and calculated the 6D parameters for each frame. The experiment was repeated four times, with the initial attitude of the mobile phone changed each time to obtain different ground impact angles.

Figure 1

The experiment focused on measuring the roll angle, which is the angle between the long side of the mobile phone and the horizontal plane. This parameter directly reflects the impact mode of the mobile phone touching the ground with its side or corner at the moment of impact, and is a key indicator affecting structural stress distribution and damage risk.

First experiment, the mobile phone model dropped in a horizontal attitude, and the roll angle changed gently. The data of the last frame captured by the high-speed camera just before touching the ground showed a roll angle of 1.98° (Figure 2), indicating that the mobile phone touched the ground in a face-impact mode. The impact energy distribution was relatively uniform, which might cause overall compressive deformation of the screen or damage to the LCD module.

Figure 2

Second experiment, the initial attitude had a certain inclination angle, and slight rotation occurred during the falling process. The roll angle reached 14.319° at the moment of touching the ground (Figure 3). The roll angle curve showed a linear increasing trend without sudden changes or jitters, and the angular velocity changed continuously, which was consistent with the dynamic response under the action of air resistance torque. At this time, the impact force was concentrated on one side of the short edge and the adjacent corners, which was prone to failures such as shell cracking and camera module deviation.

Figure 3

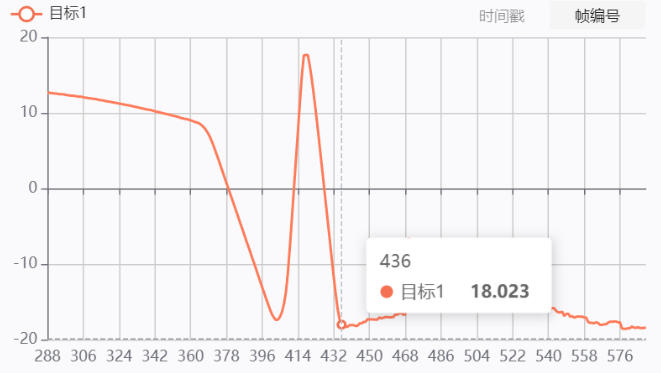

Third experiment, the initial state had a large inclination angle. The mobile phone model exhibited slight rotation under the action of air flow, and the roll angle reached 18.023° at the moment of touching the ground. The roll angle variation curve showed a non-linear acceleration characteristic, which was consistent with the trend predicted by the theoretical aerodynamic model, belonging to the edge-corner impact condition. In this state, stress was highly concentrated on a single edge line and its endpoints, which was likely to have an adverse impact on the strength of the middle frame and the connection reliability of internal brackets.

Figure 4

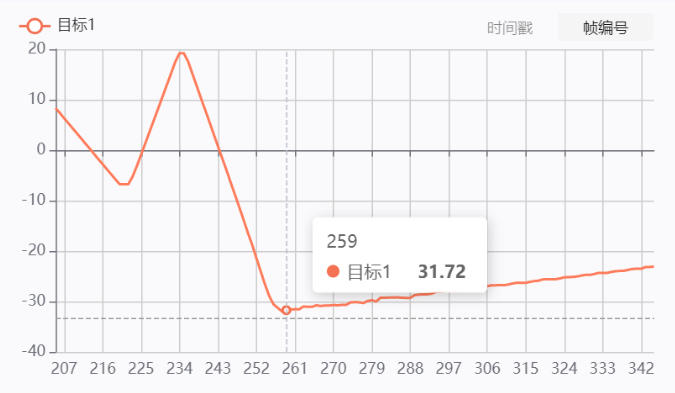

Fourth experiment, the initial drop attitude was extremely inclined, air disturbance increased, and the rotation effect of the mobile phone model was amplified. The roll angle at the moment of touching the ground was as high as 31.72° (Figure 5), belonging to the sharp-corner impact condition. In this state, the contact area was the smallest, and the instantaneous pressure was extremely high, which was likely to cause glass breakage, metal frame depression, and even physical damage to internal components. This is an extreme condition that needs to be considered in product durability design.

Figure 5

Further analysis of the time-series data captured by the high-speed camera in the four experiments showed that the change rate of the roll angle was positively correlated with the deviation of the initial attitude. The Revealer 6D measuring instrument can accurately quantify the attitude angle at the moment of ground impact, support the reconstruction of the 3D kinematic behavior throughout the drop process, and reveal the decisive influence of initial conditions on the final impact mode. It provides empirical basis for structural simulation modeling, buffer material layout optimization, and overall anti-drop design.