Concrete structures such as high-speed railways, bridges and tunnels exhibit increased brittleness and significantly decreased crack resistance when serving in high-temperature environments. Although traditional concrete has high compressive strength, its flexural strength is only 10% to 20% of its compressive strength, and it degrades acceleratedly under high temperatures due to moisture evaporation and thermal stress accumulation. To improve the toughness of concrete in high-temperature environments, waterborne polyurethane (WP) has been incorporated into concrete. Thus, there is an urgent need to study the evolution mechanism of fracture toughness of WP-modified concrete (WPMC) at different temperatures.

A research team from China Academy of Railway Sciences systematically analyzed the variation law of fracture toughness of WPMC at different temperatures using Digital Image Correlation (DIC) technology provided by HF Agile Device Co.,Ltd, and established a fracture toughness prediction model considering temperature and WP content.

2.1 Materials and Specimen Preparation

The experiment used benchmark concrete and WPMC specimens with three WP contents (5%, 10%, 15%), with dimensions of 100 mm × 100 mm × 400 mm. After standard curing for 56 days, the specimens were subjected to three-point bending tests and fracture toughness tests at 20°C, 40°C, 60°C, and 80°C.

2.2 Application of Digital Image Correlation (DIC) Technology

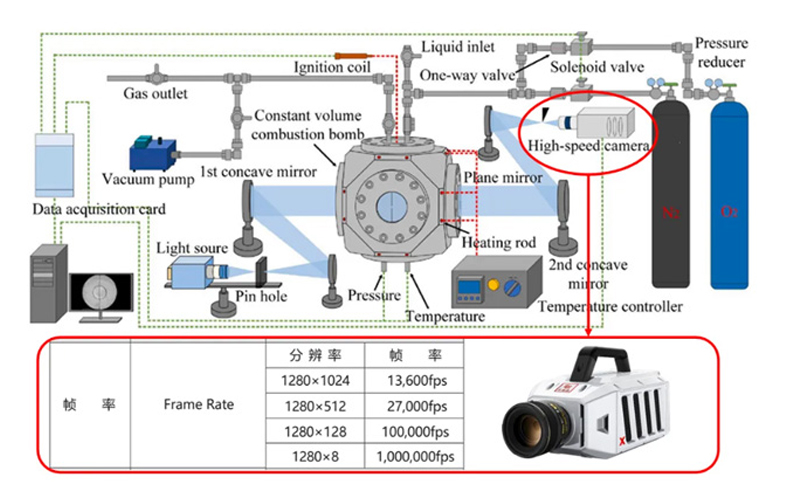

The surface of the specimen was sprayed with matte white paint as the background, and black marker points with a diameter of approximately 0.5 mm were manually sprayed to form a high-contrast speckle field. The DIC instrument operated synchronously with the electro-hydraulic servo testing machine at a frequency of 20 Hz to realize the synchronous recording of the load-deformation process. Then, key parameters such as the bottom tensile strain and crack mouth opening displacement (CMOD) were extracted through DIC software.

3.1 Analysis of Tensile Strain in the Weak Zone at the Bottom of the Specimen

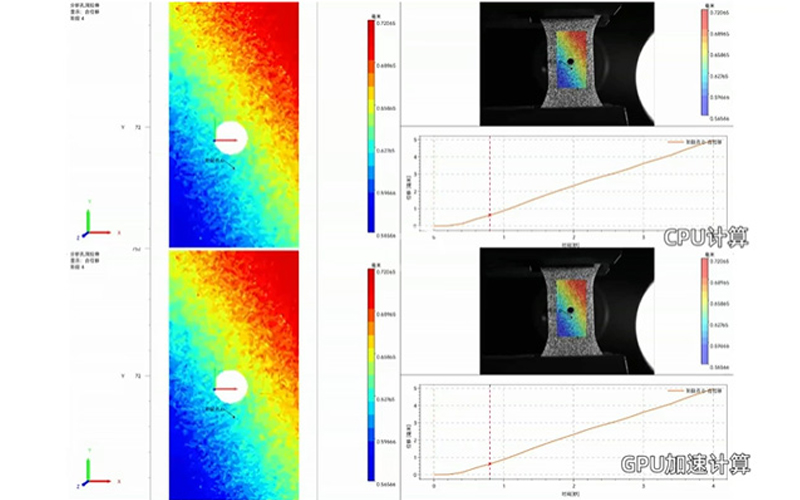

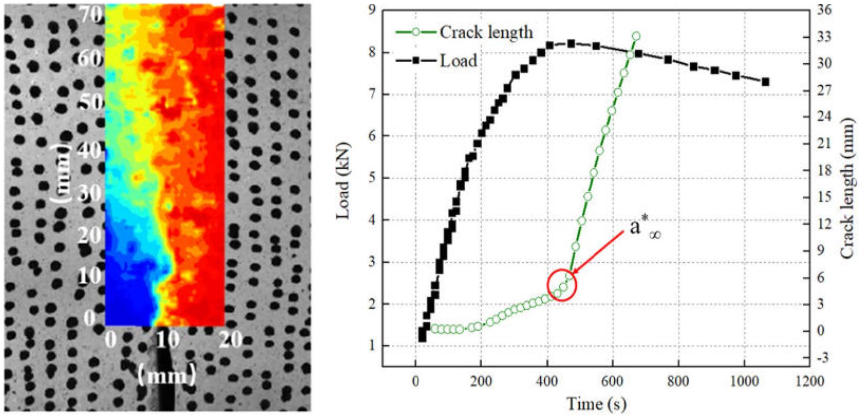

Based on the tensile strain data of the "weak zone" at the bottom of the specimen extracted by Revealer digital image correlation (DIC) technology (Figure 1), the fracture process of WPMC can be divided into two typical stages:

I: Damage Accumulation Period: At the initial stage of loading, microcracks initiate and propagate slowly, the strain at the bottom increases linearly, and elastic deformation dominates.

II: Rapid Crack Propagation Period: After the load reaches the critical value, the main crack penetrates, and the strain at the bottom rises sharply, entering the stage dominated by plastic deformation.

Figure 1

DIC measurement data show that with the increase of WP content, WPMC still maintains a high ultimate strain at high temperatures, indicating that WP significantly improves the deformation capacity of concrete.

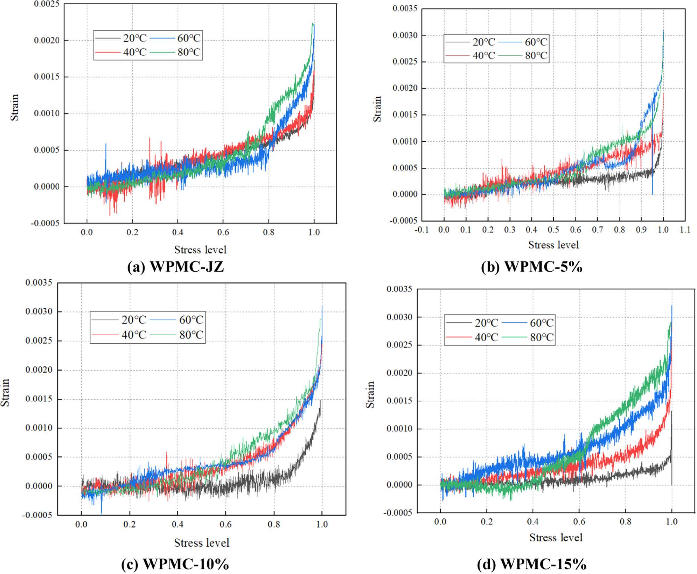

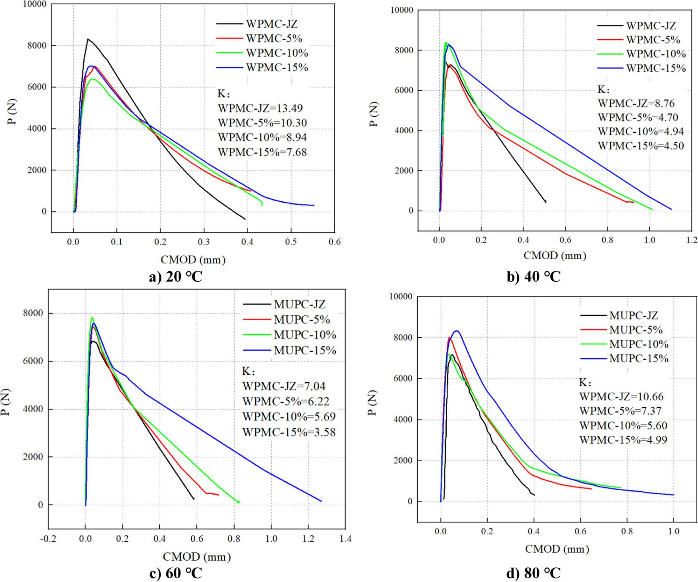

3.2 P-CMOD Curve and Toughness Evaluation

The P-CMOD (load-crack mouth opening displacement) curve is a core tool for evaluating the fracture performance of concrete. DIC technology can provide full-field deformation information as a supplement to CMOD data, and visually verify the three stages of the P-CMOD curve:

I. Linear Elastic Stage: DIC data show that in this stage, strain concentration only occurs in a very small area at the tip of the pre-existing crack, and the strain distribution of the entire beam is uniform, verifying the linear elastic behavior of the material.

II. Nonlinear Softening Stage: The load growth rate slows down, and the curve deviates from linearity, marking the start of stable propagation of microcracks. DIC measurement images show that a strain concentration zone appears in front of the crack tip, indicating the formation of a damaged zone.

III. Rapid Instability Stage: The curve of ordinary concrete drops sharply at this stage, showing brittle failure, while the curve of WPMC drops more gently.

DIC measurement data show that with the increase of WP content, Stage II is significantly prolonged, indicating that WP effectively delays the crack propagation rate and improves the fracture energy of the material.

Figure 2

3.3 Visualization of Crack Propagation Process and Verification of Boundary Effect Model (BEM)

The research team used DIC instruments to observe surface deformation, using it as a tool for accurately measuring the crack propagation history to verify and calibrate the Boundary Effect Model (BEM).

Figure 3 shows the use of a DIC measurement system to generate a full-field displacement vector map by comparing the cross-correlation calculations of speckle images before and after specimen deformation. The displacement discontinuity lines represent crack paths. By setting thresholds, the DIC software can identify the crack tip position and track its movement in real time (Figure 4), thereby obtaining precise crack extension length versus time curves. This method overcomes the limitations of traditional techniques, such as the localized nature of attached strain gauges, and captures the details of intermittent crack propagation.

Figure 3 Figure 4

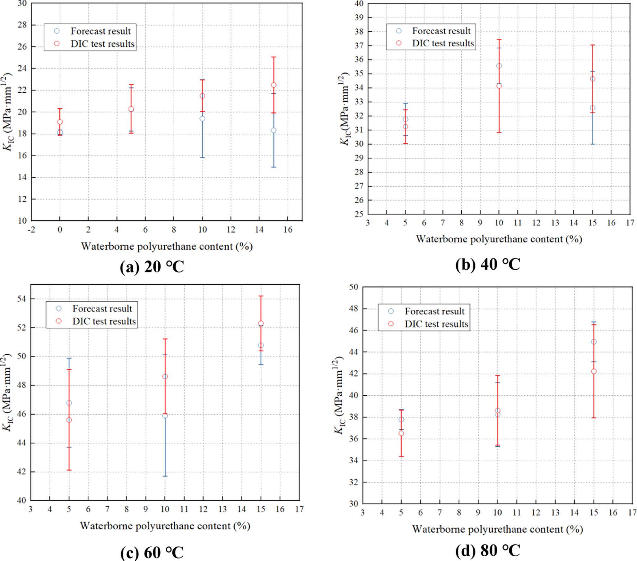

The traditional calculation of key parameters in the BEM model, such as equivalent crack length (aₑ) and characteristic crack length (a*_w), relies on theoretical formulas and assumptions. The research innovatively used the real crack propagation history measured by DIC to calibrate these parameters. By substituting the crack propagation data measured by DIC into the model for iterative inversion analysis, the accuracy and reliability of the BEM model in predicting fracture toughness (KIC) were improved. The predicted values in Figure 5 are in good agreement with the DIC measured values, verifying the effectiveness of the prediction model and highlighting the core value of DIC technology as a benchmark in the development of mechanical models.

Figure 5

By combining digital image correlation (DIC) technology with analysis, the research team systematically studied the flexural strength and fracture toughness of WPMC at different temperatures, and revealed the effects of temperature and WP content on the energy absorption and deformation capacity of WPMC:

I. The higher the WP content, the more significant the improvement in the toughness of concrete at high temperatures.

II. At 60°C, WPMC achieves the optimal energy absorption and deformation capacity.

III. By establishing a relationship model between characteristic microstructure parameters C and Cw and temperature and WP content, the fracture toughness value KIC of WPMC was successfully predicted, which is highly consistent with the DIC measurement results.

Digital image correlation (DIC) instruments provide high-precision full-field strain data for the application of concrete structures in extreme environments in railway engineering, realize non-contact, visual, and quantitative analysis of the crack propagation process, and provide strong technical support for the study of concrete fracture mechanics.