During a loss-of-coolant accident (LOCA) in nuclear reactors, the coolant inside the core may undergo sudden depressurization. This rapid pressure drop drives the liquid into a superheated state, leading to intense vapor bubble nucleation and accelerated bubble growth. These transient phase-change phenomena dominate local heat transfer behavior and strongly influence reactor thermal-hydraulic stability.

Conventional sensors such as thermocouples and pressure transducers cannot resolve the millisecond-scale bubble deformation or the coupling between bubble morphology and thermodynamic parameters.

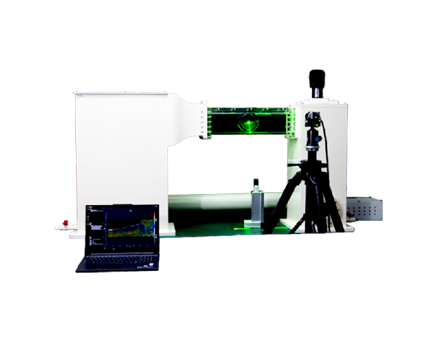

To address this challenge, a research team at Chongqing University built a dedicated rapid-depressurization visualization system enabled by the Revealer High speed camera supplied by Agile Device. With high-precision synchronization, the system captures transient bubble evolution and establishes a quantitative correlation between interfacial heat-transfer coefficients and dimensionless parameters such as the Reynolds and Jakob numbers.

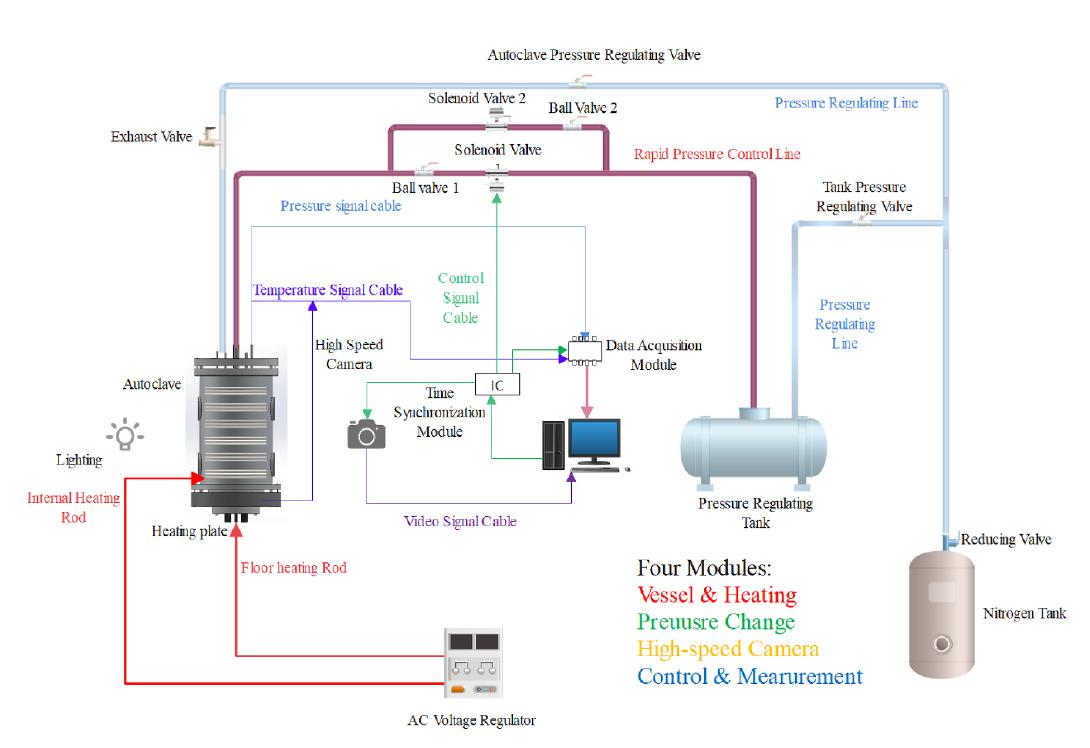

2.1 Visualization System

High-pressure vessel: Custom-built visualization autoclave rated to 4.4 MPa, equipped with cartridge heaters and a heated bottom plate to create a near-saturated and uniform thermal field.

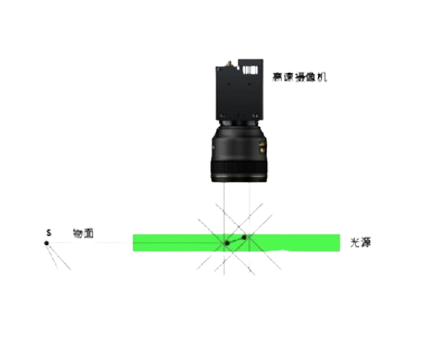

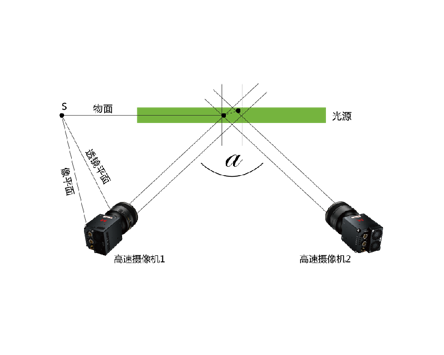

High-speed imaging & synchronization:

o Revealer High speed camera (Agile Device) with 1280×1024 resolution at 6,800 fps.

o A precise timing module that synchronizes the camera trigger with the depressurization event.

Image-processing software: Extracts bubble contour, radius, centroid position, and growth velocity.

2.2 Experimental Procedure

A total of 32 rapid-depressurization experiments were conducted under pressures ranging from 0.20 to 2.93 MPa and initial liquid temperatures of 393–514 K.

Workflow:

1. Heat deionized water to saturation temperature.

2. Initiate rapid depressurization to drive the system into a superheated state.

3. Bubbles nucleate on the heated plate and rise into the visualization window.

4. Record the transient bubble growth using the Revealer High speed camera while simultaneously collecting pressure and temperature signals.

5. Use image-processing software to compute bubble radius and projected area.

6. Synchronize morphological data with thermodynamic data for heat-transfer analysis.

3.1 Bubble Growth Dynamics

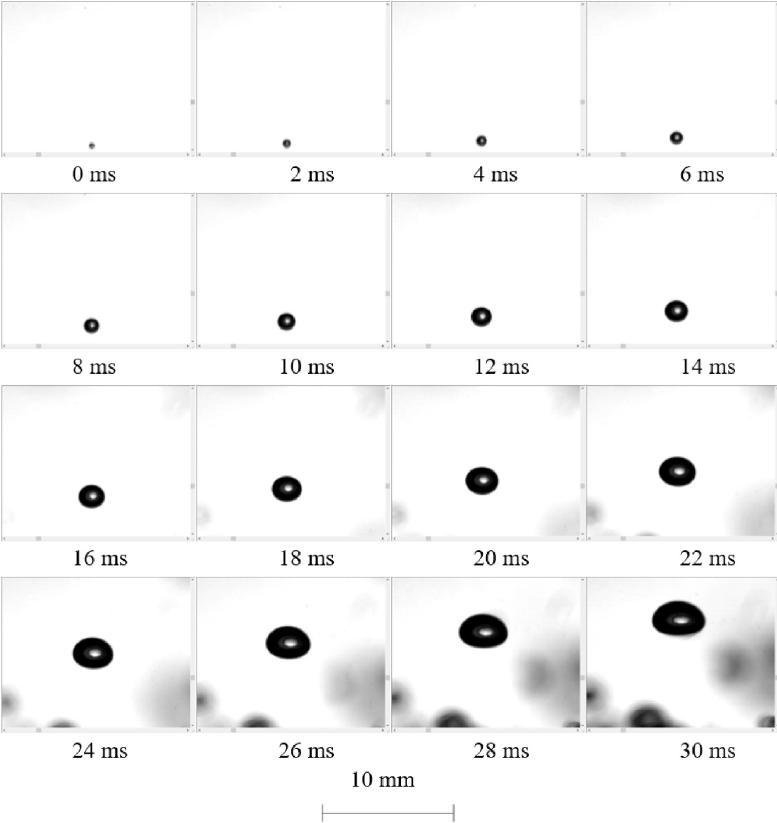

High-speed image sequences reveal the evolution of bubble morphology within the first 30 ms:

Initial bubble: nearly spherical, equivalent diameter ≈ 0.6 mm.

At 8 ms: rapid expansion; shape transitions from spherical to ellipsoidal.

At 18 ms: formation of a cap-shaped bubble.

At 28 ms: growth stabilizes with diameter ≈ 2.8 mm.

These observations confirm that the Revealer High speed camera can resolve rapid deformation and interfacial expansion during early-stage nucleation and growth.

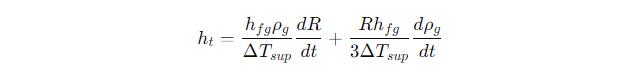

Using energy conservation, the instantaneous interfacial heat-transfer coefficient hth_tht is calculated from:

The time-averaged heat-transfer coefficient hhh is then derived by correlating bubble-radius evolution with synchronized pressure–temperature data.

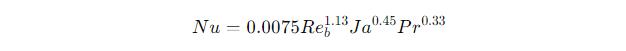

3.3 Proposed Correlation Model

A regression-based correlation for the interfacial heat-transfer coefficient was developed:

MAPE: 16.6%

Correlation coefficient: R2=0.86R^2 = 0.86R2=0.86

Compared with existing models:

Saha model: MAPE 23.8%

Wolfert model: MAPE 49.2%

The new correlation demonstrates significantly higher accuracy under rapid-depressurization conditions.

4.1 High-speed imaging capability

Using the Revealer High speed camera, millisecond-scale bubble growth and deformation were precisely recorded. The synchronized acquisition system enables sub-millisecond alignment of morphological data with pressure and temperature signals—crucial for accurate heat-transfer calculations.

4.2 New heat-transfer correlation

A new interfacial heat-transfer model was proposed that incorporates the contribution of vapor expansion work. This correlation better reflects the physics of rapid depressurization and outperforms traditional models in predictive accuracy.

4.3 Broad applicability

The imaging-synchronization framework demonstrated here can be extended to other complex phase-change and two-phase-flow scenarios, including microchannel cooling, boiling heat transfer, and cavitation studies. It provides reliable, high-fidelity experimental data for model validation and numerical simulation.