Experiment sharing | Material stretching video extensometer experiment based on high temperature DIC measurement technology

1. Experimental Background

In the fields of aerospace and nuclear power, materials and structural parts face extremely high temperature working conditions. Changes in mechanical behavior such as thermal deformation and crack propagation affect the safety and life of equipment. Digital image correlation (DIC) technology has become a powerful tool for studying material mechanics under high temperature conditions due to its advantages of non-contact, full-field measurement, and anti-interference.

Recently, engineers from Qianyanlang and R&D personnel from a domestic head equipment company jointly carried out high-temperature resistant specimen tensile experiments based on high-temperature DIC technology, verified the stability and accuracy of high-temperature DIC technology, and explored new methods for evaluating high-temperature material performance.

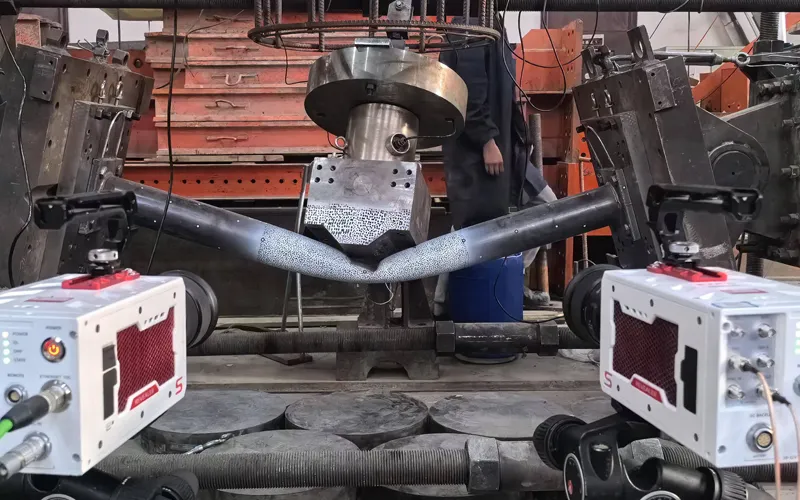

Figure 1 Schematic diagram of high temperature DIC measurement system

2. Experimental equipment

The experiment uses the Qianyanlang high temperature DIC measurement system, and the core configuration is as follows:

1) Image acquisition equipment: Revealer high-resolution camera 4096×3000 @30fps, equipped with 50mm large field of view industrial lens.

2 ) Light source system: 450nm band 100W high-power blue light source, equipped with imported filters to suppress high-temperature red light.

3) DIC software: Adopts Revealer's self- developed RDIC strain measurement and analysis software, which supports real-time full-field strain calculation and displacement tracking.

The experimental platform also includes a vacuum high-temperature furnace (maximum controllable temperature 1900°C), composite specimens, extensometers, etc.

3. Experimental procedures

1) Build a DIC measurement system to cover the target field of view of 15×15cm.

2) Spray high-temperature inorganic speckle material onto the surface of the specimen.

3) Install a blue light source and filter to reduce exposure time and improve image contrast.

4) Start the high-temperature tensile testing machine and synchronously trigger the DIC system to collect a total of 1,800 frames of images.

5) Use Revealer DIC software to measure and analyze displacement data, and compare and verify with the extensometer measurement results.

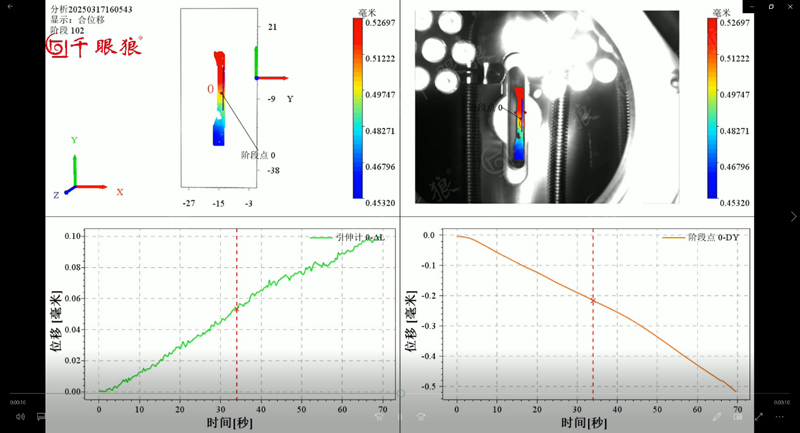

4. Experimental data and accuracy verification

The comparison of displacement data of the specimen gauge section measured by the high temperature DIC system and the traditional extensometer is as follows:

1) In the elastic stage, the deviation between the displacement data measured by high temperature DIC and the extensometer is ≤1.2%;

2) In the plastic stage, the deviation between the displacement data measured by high temperature DIC and the extensometer is ≤2.8%;

3) In the critical stage before fracture, the local speckle blurring caused by high temperature white fog is affected, with a maximum deviation of 3.5%.

The standard deviation of full-field displacement measurement is ≤0.03mm, which verifies the reliability of non-contact measurement of the high-temperature DIC system.

5. Experimental Outlook

This experiment verified the high-precision measurement capability of the DIC measurement system under extreme high temperature conditions, solved the problem of speckle material melting and suppression of red light interference in high temperature environments, and provided reliable data support for the performance evaluation of materials under high temperature tensile conditions. In the future, Qianyanlang will continue to follow the scientific research trends in the field of high temperature mechanics, continue to overcome the difficulties of ultra- high temperature DIC measurement technology, and promote the engineering application of digital image correlation DIC measurement technology under complex conditions.