——Breakthrough in polishing process of small modulus gears

As the core components in the field of precision manufacturing, small modulus gears are widely used in aerospace, industrial robots, precision instruments, medical equipment, new energy and micro-motors with advantages such as "compact structure, light weight and high precision". Traditional polishing technology has low efficiency, high cost and poor surface quality. Although electrolytic plasma polishing (EPP) is efficient and environmentally friendly, it faces the problem of uneven distribution of the surface gas layer, which affects the accuracy of the workpiece after polishing.

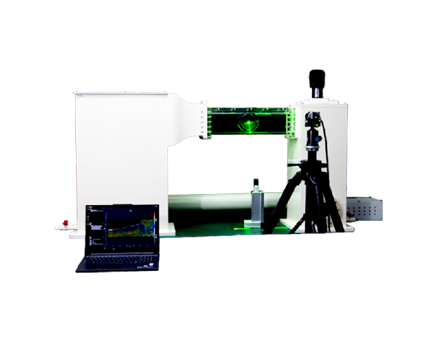

The joint research team of Hunan University of Science and Technology and Beijing University of Technology innovatively introduced ultrasonic vibration technology and carried out "Experimental research on ultrasonic-assisted electrolytic plasma polishing of small modulus gears" based on high-speed photography technology. With the help of Qianyanlang high-speed camera, the dynamic changes of the gas layer during the polishing process were captured in real time to overcome the difficulties of precision manufacturing.

The research results were published in the paper "Feasibility analysis and parameter optimization of ultrasonic assisted electrolytic plasma polishing of small modulus gears"

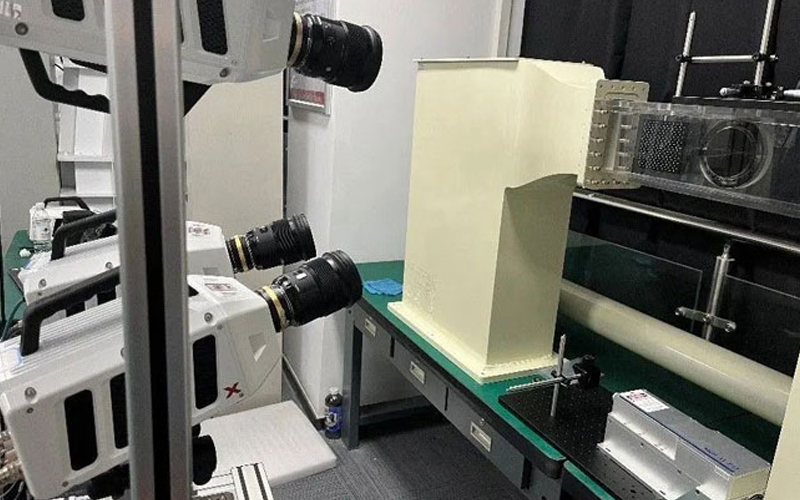

The core equipment includes the gear ultrasonic-assisted electrolytic plasma polishing system, and is equipped with Qianyanlang Revealer Mini series high-speed cameras. With its small size, large memory, and microsecond capture capability, it records the transient details of bubble generation and diffusion on the workpiece surface during polishing, providing visual data support for precision manufacturing.

The supporting equipment also includes white light interferometer, electrolytic cell, robotic arm fixture, DC power supply, etc.

The experiment is divided into two stages: comparative verification and parameter optimization.

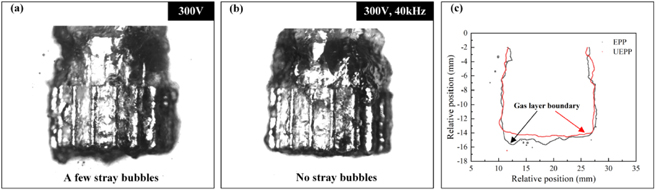

1. Comparative verification: Use the Revealer high-speed camera to compare the effects of ultrasonic vibration assistance and traditional polishing, monitor the gas layer fluctuation in real time within 4 minutes, and verify that ultrasonic technology can improve the surface roughness and tooth surface hardness of gears.

2. Parameter optimization: Based on the high-speed camera data, design orthogonal experiments of five parameters including voltage, polishing time, immersion depth, ultrasonic frequency, and tilt angle, comprehensively analyze the effects of ultrasonic-assisted electrolytic plasma polishing on small modulus gears under different process conditions, and determine the optimal process parameter combination.

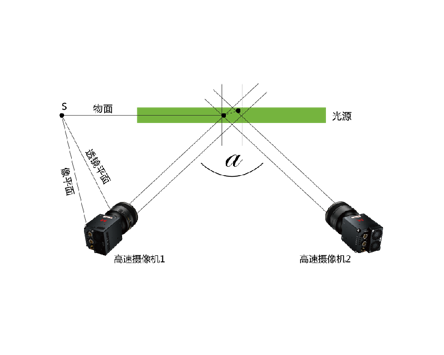

Revealer high-speed camera records the dynamic evolution of the gas layer on the workpiece surface during the electrolytic plasma polishing process at a shooting frame rate of thousands of frames per second:

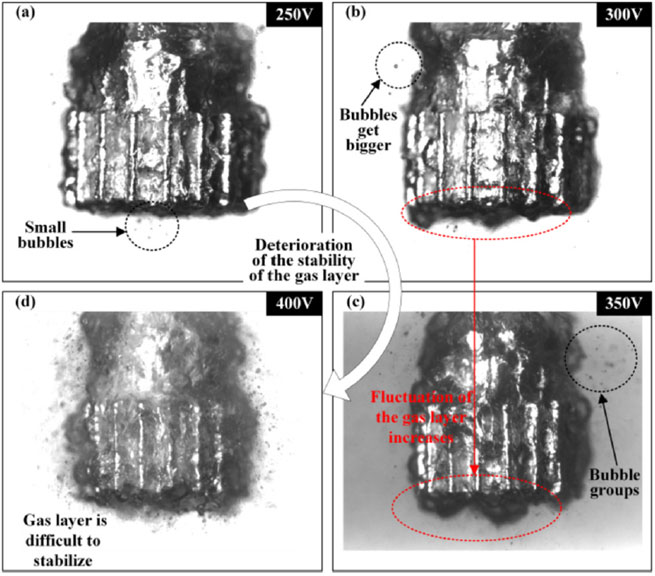

1. Gas layer distribution characteristics under different voltage conditions:

250V low voltage, the high-speed camera observed only a small amount of bubbles near the workpiece, and the gas layer was in a relatively stable state; 300V~350V, the thickness of the gas layer near the workpiece increased, the bubbles became larger, and bubble groups formed; under 400V high voltage, a large amount of gas was generated under the strong electrochemical reaction, a large amount of gas could not escape, and a large number of bubbles diffused into the processing area, which had an adverse effect on the accuracy of the polishing process.

2. The influence of ultrasonic vibration assistance on gas layer distribution

When ultrasonic vibration is not introduced, during the polishing process, the high-speed camera captures that the gas layer around the workpiece has certain fluctuations, and there are scattered bubbles around the gas layer, which affects the electric field distribution during the processing process, resulting in reduced gear accuracy after polishing. After the introduction of ultrasonic vibration, the high-speed camera captures that there are no scattered bubbles escaping from the gas layer around the workpiece. The gear gas layer boundary extracted by Matlab shows that the gas layer distribution after ultrasonic assistance is more uniform, and the gas layer thickness is reduced compared with simple electrolytic plasma polishing.

High-speed cameras dynamically capture the impact of different working conditions on the gas layer distribution in microseconds, providing an image basis for understanding the mechanism of polishing technology. At the same time, combined with image processing technology, the gas layer fluctuation is converted into quantitative indicators such as thickness standard deviation and boundary clarity. With the breakthrough of large-capacity data real-time transmission technology and artificial intelligence detection technology, high-speed cameras can realize real-time intelligent monitoring of the polishing process and closed-loop verification of precision manufacturing processes.

Qianyanlang Mini Series High-speed Cameras have a 3000 fps acquisition frame rate under 1080P high-definition frame, a compact body design, suitable for high-precision dynamic capture in small spaces, and suitable for industrial inspection and process optimization.