In the field of building fire protection, concrete structures often face the dual effects of extreme high temperature burning and fire water spray cooling, which has a significant impact on the microstructure and fracture mechanical properties of concrete.

Recently, the research team of Shanghai University has carried out experimental research based on digital image correlation technology DIC technology and acoustic emission AE technology to analyze the effect of high-temperature rapid cooling on the fracture properties of high-performance concrete (HPC) with high precision.

For details, please see the paper "Study on the fracture mechanical properties of high performance concrete (HPC) with rapid cooling after high temperature"

It consists of the Revealer DIC system and other supporting equipment.

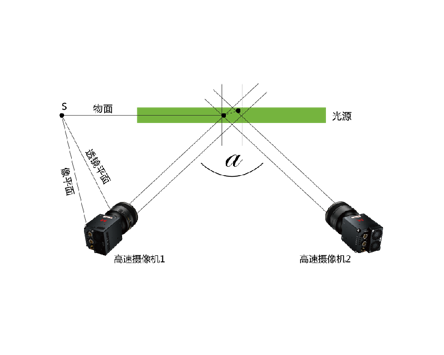

1. DIC measurement system: Revealer DIC 3D measurement equipment, including 2 ultra-high-definition high-speed cameras, see Figure 1 for details. RDIC strain field analysis software, supports real-time generation of displacement and strain cloud maps, supports crack propagation analysis, can locate crack tips, and calculate opening angles.

Figure 1 Revealer DIC measurement system

2. Supporting equipment:

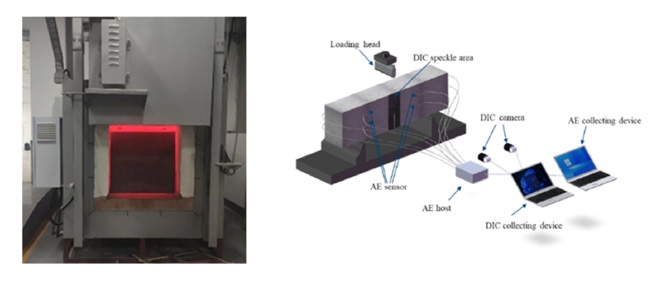

1) High temperature furnace: up to 1000°C, temperature control accuracy ±1°C, simulating high temperature environment of fire.

2) Hydraulic servo: three-bending beam loading (0.3 mm/min displacement control), load sensor measurement range 0 kN~2000 kN, displacement sensor measurement range 0 mm~200 mm, extensometer measurement range 0 mm~10 mm, used for synchronous collection of load-displacement data.

3) Acoustic emission system: 50-400 kHz sensor, used to capture the acoustic signal of crack extension.

1.1 Specimen preparation: The research team prepared three-point bending beam specimens of two materials, ordinary concrete (PC) and high-performance concrete (HPC). The specimen size was 550mm×150mm×100mm, the pre-cut length was 60mm, the cut height ratio was 0.4, the span was 450mm, and the span height ratio was 3.

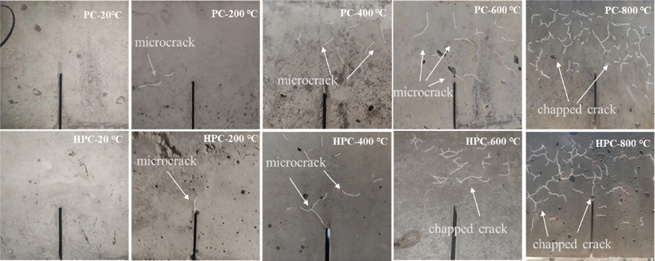

1.2 High temperature and cooling treatment: After pre-drying, the specimens were treated at high temperature conditions of 20°C, 200°C, 400°C, 600°C and 800°C, and then immediately placed in a cooling pool for 90 minutes to simulate a fire sprinkler scene.

Figure 2 Performance characteristics of concrete after high temperature

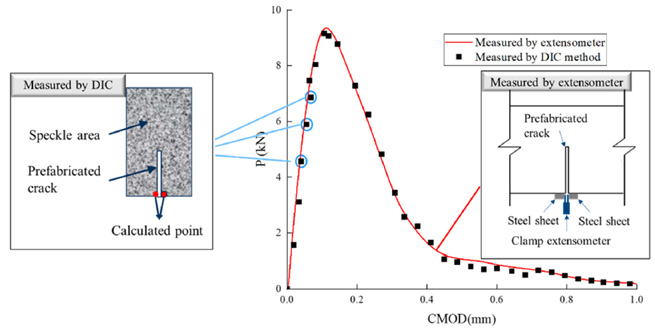

1.3 Loading test: The cooled specimen was subjected to a three-point bending beam loading test. The specimen was loaded at 0.3 mm/min using a hydraulic servo test machine, and the speckle image of the specimen surface was collected through the DIC system. The load-time curve and displacement-time curve of the hydraulic servo machine were recorded at the same time, and the load-crack opening displacement CMOD value was recorded using an extensometer, which was highly consistent with the DIC measurement results, as shown in Figure 3.

Figure 3 Comparison of CMOD values measured by DIC and extensometer

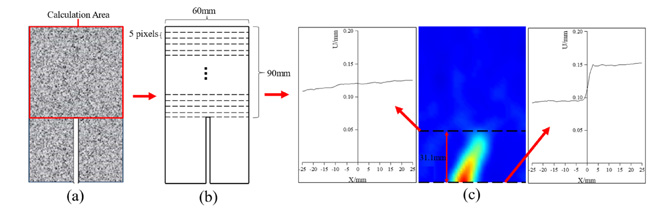

1.4 Data analysis: The collected images were analyzed by the DIC system, a line crack was drawn every 5 pixels, the lateral displacement jump point was analyzed, and the crack tip was located, as shown in Figure 4. At the same time, the damage process of concrete was analyzed by combining acoustic emission (AE) technology.

Figure 4 Schematic diagram of crack length calculation

The DIC measurement system analysis found that the HPC crack initiation stage significantly advanced with temperature, which was Pre-60% peak load at room temperature and advanced to Pre-10% at 800°C. DIC measured that the crack growth rate of HPC was uniform after 600°C, while PC softened at 200°C, proving that HPC has better interface density. At the same time, the DIC and extensometer and AE measurement data were mutually verified, which also verified the reliability of non-contact measurement.

Through the Revealer DIC measurement system, researchers revealed the influence of different material compositions and proportions on the fracture performance of concrete. Under complex loading conditions, the DIC measurement system can monitor the deformation and crack development of concrete in real time, provide dynamic data support for in-depth understanding of the mechanical behavior of concrete, and promote the research and innovation of building materials to a higher level.