At the recently concluded "2025 International Conference on Precision Manufacturing and the 22nd Shenyang Science Academic Annual Conference", topics such as ultra-precision machining, intelligent manufacturing, and precision measurement became the focus of attention among researchers and engineers. As a "time microscope" for capturing dynamic processes, high-speed cameras play an irreplaceable role in revealing manufacturing mechanisms, optimizing processes, and ensuring equipment reliability.

For engineers and researchers seeking a reliable high-speed camera for manufacturing process analysis, understanding these applications is critical for driving innovation and ensuring quality.

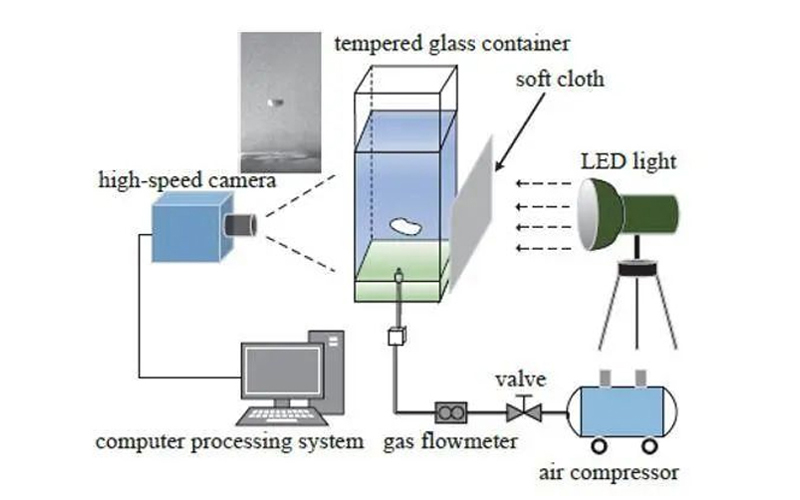

The interaction between the tool and the workpiece during metal cutting is extremely short-lived. Cutting force, tool wear, and cutting morphology affect surface quality and tool life. By performing microsecond-level imaging of the cutting area, high-speed cameras can analyze the load-bearing state of the cutting edge, the chip formation mechanism, and the tool failure process.

An automotive R&D team used a Revealer high-speed camera with core parameters of 1280×1024 @5000fps to capture dynamic images of the cutting area, analyzing the wear morphology of the cutting edge and the cutting flow path. This provided an experimental basis for tool coating design and cutting parameter optimization.

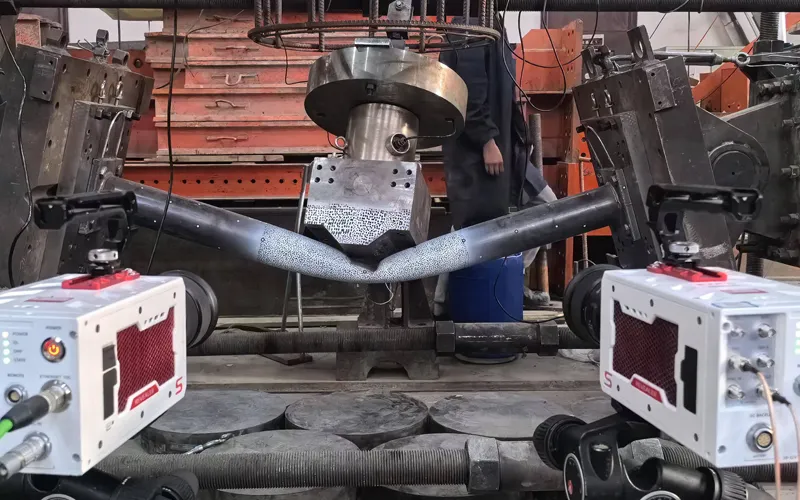

The end effector of a robot is prone to vibration during high-speed grasping and trajectory tracking, which affects positioning accuracy and operational stability. High-speed cameras can record the dynamic response of robot joints and ends during start-stop and direction change processes.

In a six-axis robot experiment, a Revealer high-speed camera S1315 with large memory was used, with parameters of 1280×1024 @2000fps, to observe transient images during the grasping process of the six-axis robot. Image analysis software was used to extract vibration frequency and amplitude, providing a basis for improving the structural stiffness of the robot and debugging control algorithms.

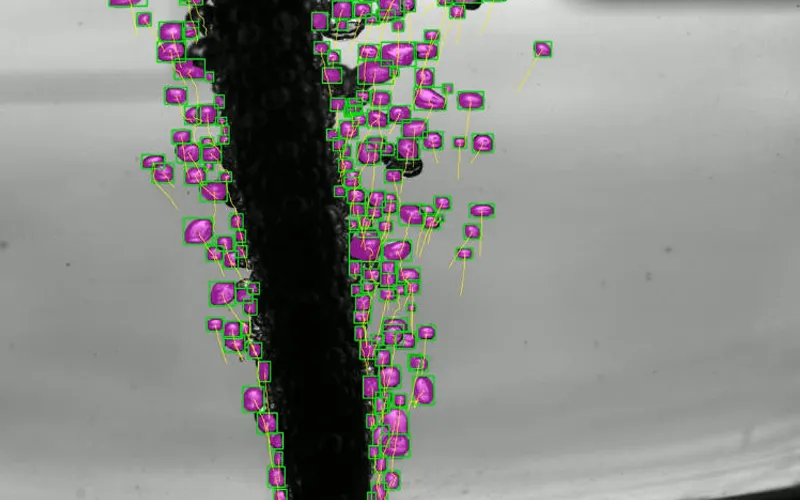

During the winding process of lithium battery pole pieces, the pole pieces are prone to vibration, splashing, and deformation during high-speed transmission and die-cutting. Traditional industrial cameras are difficult to capture such high-speed dynamic behaviors. At a high-speed pole piece winding station of a lithium battery manufacturer, a Revealer Mini-series high-speed camera (small size with large memory) was used to record the movement state of pole pieces between transmission rollers and micro-vibrations at the moment of cutting in high definition with parameters of 1920×1080 @2000fps. This provided a visual basis for optimizing the rigidity of winding equipment and adjusting process parameters.

As a key electronic control component, the contact opening/closing speed and spring rebound characteristics of relays directly affect the reliability of electrical systems. Using high-speed cameras combined with image analysis software, it is possible to non-contact track marker points and achieve quantitative analysis of mechanism displacement, speed, and acceleration.

In a relay test, a Revealer high-speed camera S1315 was used to capture the spring compression and mechanism closing process at an acquisition speed of 5000fps. Motion analysis software was used to track the concentric circle marker points on the opening/closing mechanism, extracting the vertical displacement of the concentric circle marker points from the start of movement to the rebound process and the average speed of the opening/closing mechanism. This provided precise data for relay structural design and service life evaluation.

High-speed cameras have evolved from "image recording tools" to "core equipment for process diagnosis and optimization" in precision manufacturing. Their capabilities in capturing transient processes, measuring motion parameters, and analyzing micro-phenomena provide data support for precision machining, assembly, and inspection processes. With the development of high-speed imaging technology, high-speed cameras will play a more important role in fields such as ultra-precision manufacturing, new energy, semiconductor equipment, and robot systems.