Under low temperature environment, the strength of steel structure increases while the toughness decreases, which is easy to cause brittle fracture. Traditional strain measurement methods such as strain gauges are costly, easy to damage, and have limited measurement areas.

Recently, researchers from the civil engineering laboratory of a key university introduced digital image correlation technology DIC and carried out a drop hammer impact steel pipe experiment based on a low-temperature high-speed DIC measurement system. The purpose is to study the influence of low temperature on the strain distribution of steel structure and provide experimental data reference for the performance research of steel structure in extremely cold areas.

This experiment uses the high-speed DIC system independently developed by Revealer. The core equipment includes:

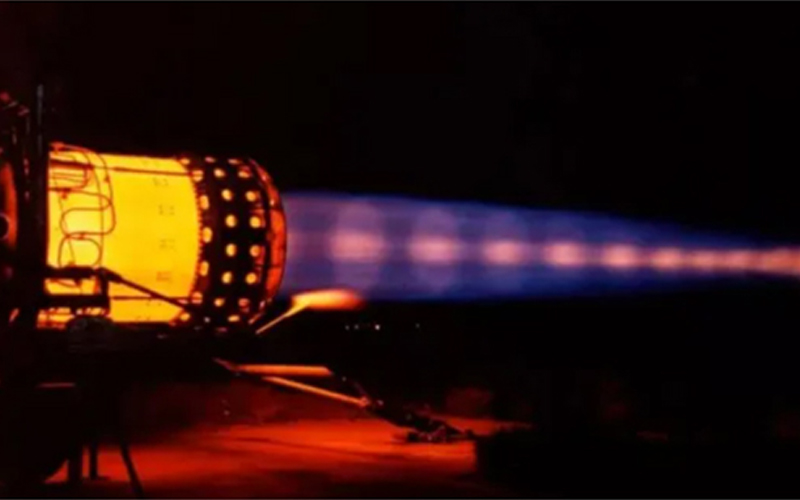

(1) High-speed camera, S1315M, with industry benchmark parameters of 15,000 frames at 1280×1024 resolution, which can capture the transient details of high-speed impact.

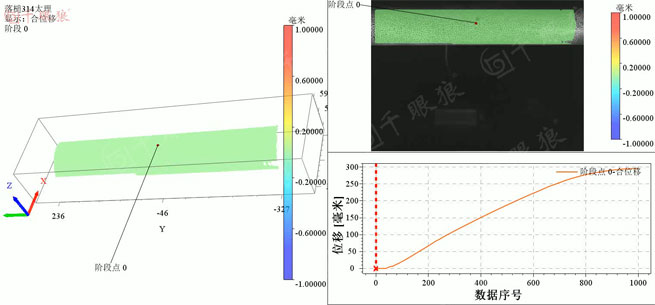

(2) 3D3C RDIC software, combined with the easy-to-use high-speed camera acquisition software RCC, post-processes the acquired images and efficiently analyzes the full-field data of displacement and strain.

(3) Drop hammer device, customized high-precision drop hammer device, hammer weight 50kg, maximum drop hammer height 3m, impact speed up to 5m/s, providing the impact load required for the experiment.

(4) Steel pipe specimen, cylindrical, 3m long, 20cm in diameter, observe the strain distribution and deflection change in its impact area.

Other supporting equipment includes low-temperature speckle paint preparation specimen, 28mm spacing high-precision calibration plate, high-power light source system, etc.

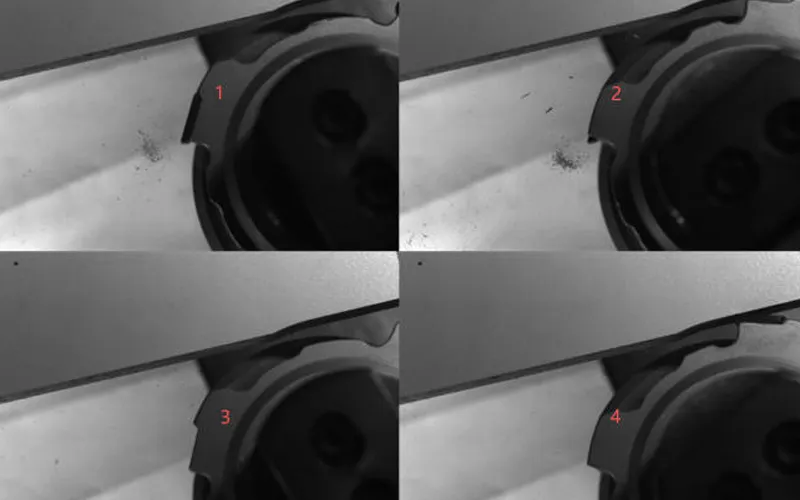

(1) Prepare the surface speckle of the specimens in the normal temperature group and the low temperature group. The low temperature group uses a special speckle paint of -30°C. The steel pipe specimen is fixed on the impact table, and the 28mm spacing dot plate is calibrated to complete the three-dimensional spatial positioning.

(2) The critical drop hammer height of the normal temperature group is determined through a preliminary experiment. After the low temperature group specimen is placed in a -30°C environment for cooling, it is impacted at the same height, and the three-dimensional high-speed DIC measurement system is started simultaneously to collect experimental data.

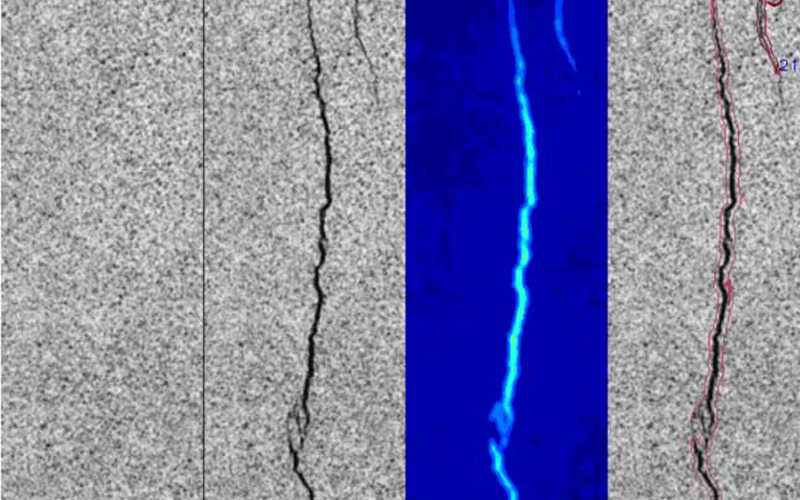

(3) The data is post-processed using Revealer 3D DIC measurement software to compare and analyze the specimen strain at normal temperature and low temperature.

4. Experimental data and conclusions

Revealer 3D high-speed DIC measurement system recorded the transient process of the drop hammer impacting the steel pipe in real time at a shooting frame rate of 15,000 frames per second. After processing by the DIC measurement software:

(1) The peak strain value of the column foot in the low-temperature group increased by 45% compared with the normal temperature group, and the strain value of the windward side of the column was significantly higher than that of the leeward side, with an increase of 52%, indicating that the environmental coupling effect aggravates the local stress concentration.

(2) According to DIC calculation, the maximum deflection value of the steel pipe under impact is 8.3mm, which is only 1% different from the laser ranging result. The high accuracy of the DIC system measurement is verified.

The success of the drop hammer impact experiment under low temperature environment provides valuable data and reliable methods for further studying the performance of steel structures under low temperature. The subsequent scientific research team will conduct in-depth research on the impact resistance of various types of steel structures and other composite materials. Revealer will be committed to the research and development of advanced DIC strain measurement systems to provide accurate, efficient and easy-to-use DIC measurement solutions for scientific research and engineering fields.

Revealer RDIC-3D 3D full-field high-speed strain measurement system consists of 2 Revealer high-speed cameras, synchronous triggers, measurement software, calibration plates, and graphic workstations. It supports instantaneous measurement of the spatial 3D coordinates of objects, displacement and strain data under extreme impact loads.

#DigitalImageCorrelation #DICMeasurement #StrainMeasurement #DICSoftware #ThousandEyedWolfDIC #HighSpeedDIC #3DDIC #Revealer