The pressure field, a scalar distribution function describing pressure within a flow, is vital in fluid dynamics. Its spatial change (pressure gradient) reflects the momentum transfer in fluid micro-elements. Pressure measurement is critical because it directly determines aerodynamic performance, structural response, and energy transfer efficiency in applications such as aircraft lift, ship structural load analysis, and blood flow impact on heart valves.

Traditional contact pressure measurement techniques (e.g., pressure sensors) are invasive, disturbing the flow and providing only limited discrete pressure points. Non-contact methods based on density-refraction-optics (Schlieren/Shadowgraph, BOS) rely on density change as an intermediary physical quantity to convert to pressure, but they are limited to compressible gas fields or specialized liquid flows and cannot measure the full-field pressure distribution.

Engineers at Agile Device have developed a technique to reconstruct the full internal pressure field. This method utilizes the dynamic relationship between the pressure gradient term and the velocity field within the Navier-Stokes equations, using the velocity field measured by their proprietary Particle Image Velocimetry (PIV) system.

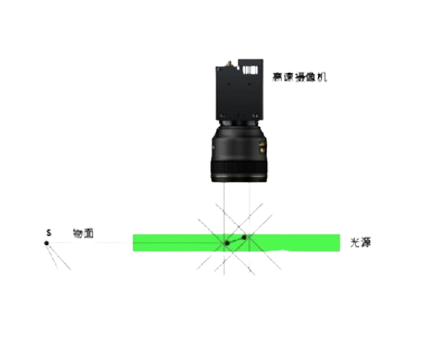

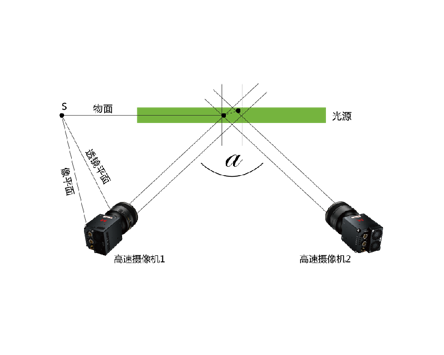

Particle Image Velocimetry (PIV) is an ideal non-contact, full-field, high-spatial resolution measurement technique, providing the necessary velocity field input for pressure field reconstruction.

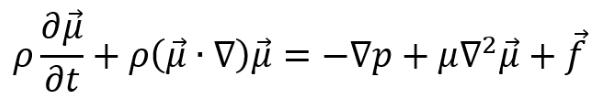

The physical link between the velocity and pressure fields is strictly defined by the Navier-Stokes (N-S) equation. For incompressible fluids, the equation is:

By taking the divergence of the N-S equation and applying the incompressibility condition the Poisson equation for pressure can be derived:

This equation shows that the pressure field is directly related to the divergence of the convective acceleration (inertial force) of the velocity field.

The pressure reconstruction steps using the Agile Device Revealer PIV software, RFlow4, are:

Acquire the instantaneous velocity field by using the PIV measurement system.

Calculate the source term on the right side of the Poisson equation, which represents the inertial force (convective acceleration) of the flow field, using the measured velocity field.

Solve the Poisson equation using numerical methods (like finite difference) with appropriate boundary conditions to obtain the full-field pressure distribution.

Compared to density-refraction-optics pressure inversion techniques, the PIV velocity-field-based pressure reconstruction developed by Agile Device algorithm engineers offers distinct advantages in applicability and ease of use:

Feature | PIV Velocity Field Reconstruction | Density-Refraction-Optics (Schlieren/Shadowgraph) |

Applicability | Based on momentum conservation, independent of medium compressibility. Applicable to incompressible flows (like most water flows) and compressible flows. Indispensable for liquid flow pressure measurement20. | Limited by whether the flow field produces measurable changes in the refractive index (density). Primarily applicable to compressible gases or special liquid flows with significant density gradients21. |

Ease of Use | Relies on mature PIV hardware (e.g., High Speed Camera, laser, synchronizer). The operation process is standardized and easy to use22. | Requires highly demanding experimental setup, calibration, and environmental stability (anti-vibration) for the optical path, making preparation difficult23. |

To validate the efficacy of the PIV velocity-field pressure reconstruction technique, Revealer algorithm engineers conducted simulations, including ship slamming pressure reconstruction and comparison with Fluent CFD simulation results.

This experiment simulated the transient impact pressure generated when a ship hull enters the water. The Revealer High Speed 2D2C-PIV system recorded the initial flow field.

Results: The PIV-measured velocity field clearly showed jet formation and rapid contact line movement. The reconstructed pressure field revealed that the high-pressure region consistently concentrated at the jet root, near the contact point between the water and the ship bottom, moving along with the contact line.

Fig.1 Initial flow field recorded by high-speed 2D2C-PIV

Fig. 2 Pressure field inverted from velocity field measured by PIV

To verify the reliability of the PIV-reconstructed pressure field , the results were compared against the professional CFD software Fluent.

Method: The velocity field calculated by Fluent was imported into the Revealer PIV software RFlow for pressure reconstruction. The reconstructed result was then compared to the original pressure field data from the simulation.

Fig. 3 The velocity field of airfoil flow calculated by Fluent software

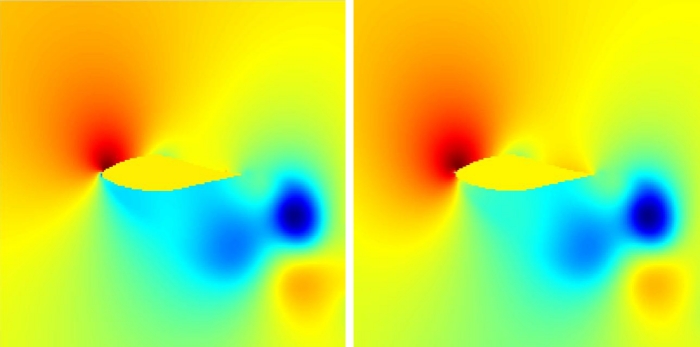

Fig.4 Pressure field reconstructed by PIV Fig.5 Pressure field of Fluent simulation

Results: The Fluent simulation and the PIV-reconstructed pressure fields showed a high degree of consistency in overall structure, both clearly displaying the high-pressure area at the airfoil's leading edge (red), the low-pressure area on the suction surface (blue), and the pressure recovery region at the trailing edge.

The pressure field reconstruction technique based on PIV velocity fields:

Solves for pressure through the "motion→acceleration→N-S equation" method, relying on standard PIV experiments

Is applicable to both gas and liquid media.

Thanks to data acquisition from Revealer's self-developed PIV High Speed Camera systems, the technique is suitable for low-speed to medium-high-speed flow scenarios.

Compared to density-optical pressure inversion techniques, PIV-based pressure reconstruction has greater potential for engineering applications. It provides physically-based empirical data for CFD modeling and is especially valuable for complex flow scenarios like separated flows, turbulence, cavitation, and vortex shedding, where CFD simulation is often challenging.

As the temporal sampling capability of the Revealer High Speed Camera continues to advance, the applicability of the PIV pressure field reconstruction technique will further increase, promising broader application in aerospace, marine engineering, energy equipment, and biomedical fields.