Digital Image Correlation (DIC) has ushered in a new era for digital image correlation strain measurement. This non-contact, optical technique provides full-field deformation data that is revolutionizing how engineers and researchers analyze materials and structures. Unlike traditional methods, DIC offers unparalleled insights into strain distribution and behavior.

Digital image correlation (DIC) strain measurement systems work by smearing random dots or patterns on the surface of an object and using a high-speed or high-resolution camera to take images of the object under different loads. The system analyzes the movement of the points in these images and calculates the displacement field and deformation field of the object. The specific steps are as follows:

Speckle production: Create a pattern with high contrast and random grayscale distribution on the surface of the specimen by spray painting, hollow spraying, stickers, etc.

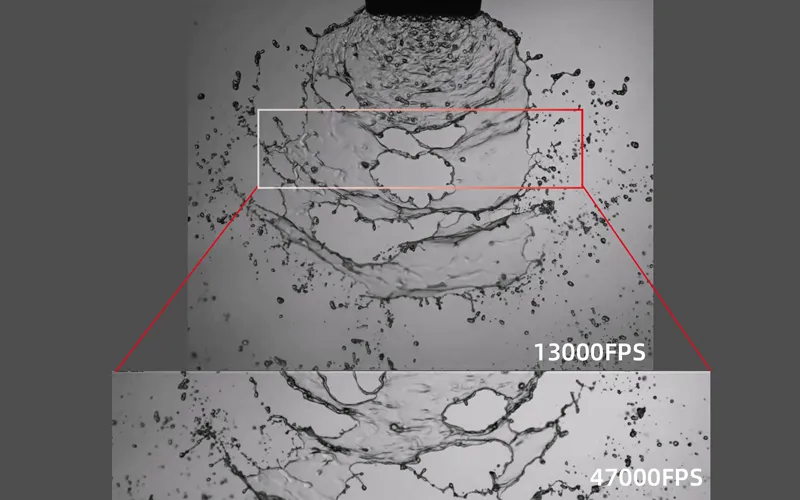

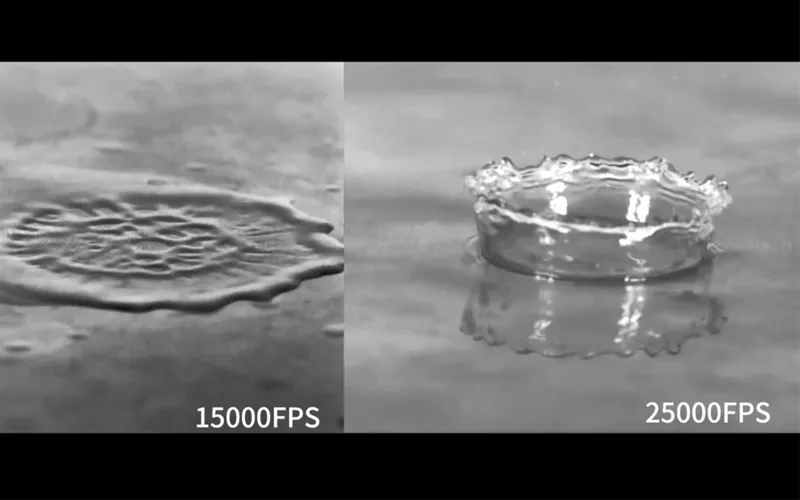

Image acquisition: Use a high-speed camera or a high-resolution camera to capture images of the object under different loading conditions.

Image processing: Use digital image correlation system (DIC) algorithms to track feature points in the image and calculate the displacement field of the object.

Data analysis: Further process these displacement data to obtain important mechanical performance indicators such as strain and stress.

The DIC strain measurement system is an efficient, non-contact deformation measurement method and has become an indispensable tool in modern mechanical experiments. It has a wide range of applications and can provide high-precision data, especially for complex scenarios that cannot be easily measured by traditional methods.

Building structure monitoring:

Application scenarios: Monitoring the deformation of structures such as buildings and bridges under load. Advantages: Helping engineers assess the safety and stability of structures.

Material testing:

Application scenario: Real-time recording of the distribution of surface strain of materials during stretching or compression. Advantages: Provide data support for the research and development of new materials.

Automotive and Aerospace:

Application scenarios: Testing the deformation of the vehicle body structure during a collision; Detecting the stress distribution of aircraft parts. Advantages: Providing more comprehensive and detailed data with higher spatial resolution.

The Importance of DIC Strain Measurement Systems in Materials Testing

In the field of material testing, DIC strain measurement systems are rapidly becoming an important testing method. Traditional material testing methods often rely on contact sensors, which may affect the accuracy of test results. DIC technology, on the other hand, uses non-contact measurement to achieve accurate monitoring of material deformation and strain.

Tensile test:

Application scenario: Provide full-field strain distribution map to help researchers better understand the behavior of materials under different stresses.

Advantages: It shows the strain concentration area of the material before fracture, providing data support for improving material performance.

Fatigue test:

Application scenario: Real-time monitoring of material behavior under repeated loading.

Benefits: Helps researchers identify potential fatigue crack initiation locations, thereby providing guidance for material design and use.

Shock Test:

Application scenario: Record the deformation and strain of materials under impact load.

Benefits: Provides real-time data to help researchers analyze how materials perform under extreme conditions.

Advantages and Challenges of DIC Strain Measurement Systems

Compared with traditional mechanical measurement methods, the DIC strain measurement system has obvious advantages, but it also faces some challenges.

Advantages:

Non-contact measurement: avoids measurement errors caused by contact in traditional methods.

Multi- point data capture: Capture displacement data of multiple points simultaneously to obtain more comprehensive deformation information.

High spatial resolution: down to the sub-millimeter level, very suitable for precise measurement of tiny deformations.

challenge:

Equipment requirements: A high-speed camera or a high-resolution camera and a stable lighting environment are required.

Complex data processing: Post-data processing is relatively complex and requires the use of professional software for analysis.

With the continuous advancement of science and technology, the DIC strain measurement system has broad prospects for future development. In the future, DIC technology is expected to be applied in more fields, such as biomedical engineering, microelectronic device testing, etc. In addition, with the continuous development of computer vision and image processing technology, the accuracy and efficiency of DIC systems will continue to improve, providing more reliable data support for mechanical measurement and material testing.