Original Research Powered by Revealer

Carbon-based materials such as graphene and carbon nanotubes exhibit electro-mechanical expansion when subjected to electrical excitation. This phenomenon is governed by multi-field coupling involving electrical charge transport, Joule heating, and lattice vibrations. Understanding this behavior is crucial for advancing applications in:

Flexible electronics

Electroactive actuators

Artificial muscles

High-performance energy devices

Traditional measurement methods cannot capture millisecond-scale expansion dynamics, especially under rapid thermomechanical transitions.

To overcome this limitation, a research laboratory deployed a high-speed Digital Image Correlation (DIC) system developed by Agile Device, enabling non-contact, full-field, high-frame-rate measurement of displacement and strain evolution on the surface of carbon specimens. This provides essential experimental validation for multi-physics simulation models.

2.1 Equipment Setup

High Speed Camera:

Agile Device’s self-developed Revealer G520_Pro (2560×1920 @ 2000 fps) was used to capture transient expansion sequences of the carbon specimen.

Digital Image Correlation (DIC) Software:

Revealer RDIC software was used to track digital speckle patterns and compute per-frame displacement and Lagrangian strain fields.

Specimen & Power Supply:

The test specimen was a multilayer graphite composite.

A programmable power supply delivered controllable current and voltage to simulate realistic electrochemical conditions.

2.2 Experimental Procedure

1. Construct the high-speed DIC measurement system with a 5 cm × 5 cm field of view.

2. Position the carbon material specimen and activate the electrical loading system.

3. Optimize LED illumination to minimize surface glare; configure the High Speed Camera (Revealer G520_Pro) at 500 fps over a 1-second capture window.

4. Perform DIC post-processing to compute displacement and strain fields.

2.3 Selection of Measurement Points

Two representative points were selected to capture spatially heterogeneous expansion behavior:

Point 0 (Center)

Minimal boundary influence, reflecting the intrinsic thermo-electro-mechanical response.

Point 1 (Edge)

Influenced by boundary constraints and current density gradients; used to evaluate stress concentration and damage susceptibility.

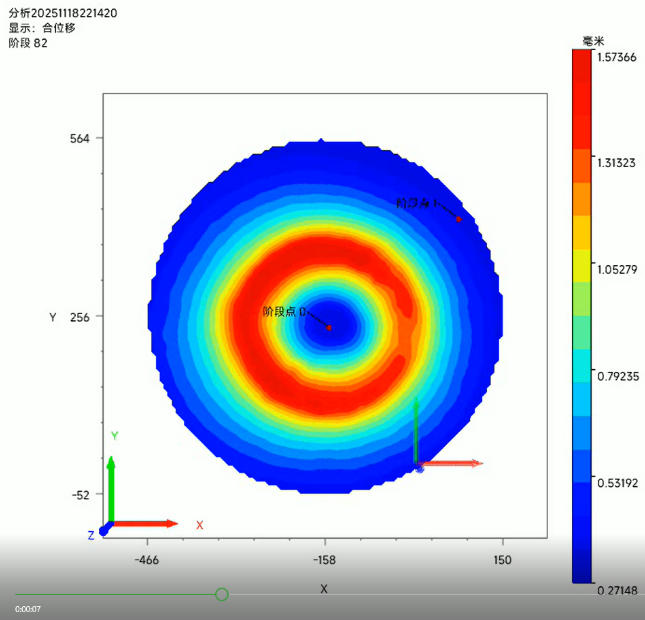

Using the High Speed Camera data and RDIC processing, the research team acquired full-field displacement and strain evolution of the carbon specimen within 1.0 second after electrical excitation. Analysis focused on the in-plane Exx strain along the primary current direction and the composite displacement field.

3.1 Temporal Evolution of Strain

Center Point (Point 0)

0–0.5 s: Exx strain rapidly increases in a parabolic trend, reaching a peak of 30,000 με.

o Joule heating leads to temperature rise.

o Thermal expansion increases interlayer spacing.

o Rapid electromechanical coupling produces steep strain growth.

0.5–1.0 s: Nonlinear decay to 5,000 με as:

o Stress relaxation initiates post-peak.

o Microstructural adjustments occur within the porous carbon matrix.

Edge Point (Point 1)

Exhibits negative Exx strain, following an inverted parabolic trend.

Minimum strain of −3,000 με at 0.5 s indicates radial compression caused by central expansion.

Recovery towards zero after 0.5 s suggests gradual relaxation of boundary-induced stresses.

These behaviors reflect classical Poisson-effect-driven radial interactions during electrothermal expansion.

3.2 Spatial Characteristics of the Displacement Field

A distinct dome-shaped displacement gradient forms from the edge toward the center:

Composite displacement:

o Edge region: > 0.8 mm

o Center region: < 0.3 mm

o Maximum displacement appears in an annular ring between center and edge.

Center Region

Exhibits mostly out-of-plane (lifting) displacement with minimal radial movement.

Combined vector displacement remains < 0.3 mm.

Annular High-Displacement Band

Acts as a transitional zone linking the strongly expanding center and constrained edges.

Experiences both radial tension and significant out-of-plane deformation, producing the highest composite displacement.

Edge Region

Although constrained by fixtures and geometry, the edges still show >0.8 mm displacement due to internal pushing by the expanding central region.

Confirms strong non-uniform expansion behavior during electrical loading.

I. The high-speed Digital Image Correlation (DIC) system developed by Agile Device and powered by Revealer successfully captured millisecond-scale strain and displacement fields during electrical excitation of carbon materials.

II. The High Speed Camera–DIC system revealed pronounced non-uniform expansion governed by electro-thermal-mechanical coupling:

Central region undergoes Joule-heating-driven expansion.

Edge region experiences negative strain due to boundary constraints.

Annular region exhibits compounded lifting and radial tension, forming a clear dome-shaped gradient distribution.

III. This dome-shaped deformation pattern highlights the zones of energy concentration within carbon materials during actuation.

It provides critical insights for:

Designing electroactive material structures

Enhancing fatigue resistance

Optimizing actuator performance

Identifying mechanically vulnerable regions

The findings demonstrate the value of combining Revealer High Speed Camera technology with Agile Device’s Digital Image Correlation (DIC) tools for advanced multi-physics material research.