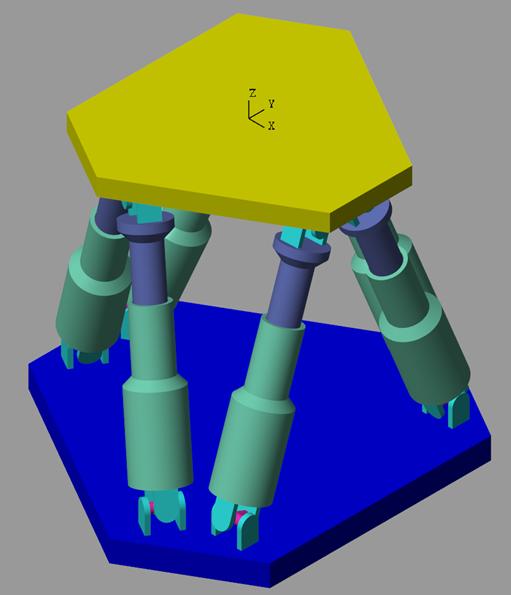

A six-degree-of-freedom (6-DOF) motion platform is a core instrument in metrology and motion-simulation applications. It enables combined translation (X, Y, Z) and rotation (Roll, Pitch, Yaw) in 3D space, and is widely used in aerospace navigation calibration, ship and marine engineering, robotics, vehicle dynamics, and precision motion verification.

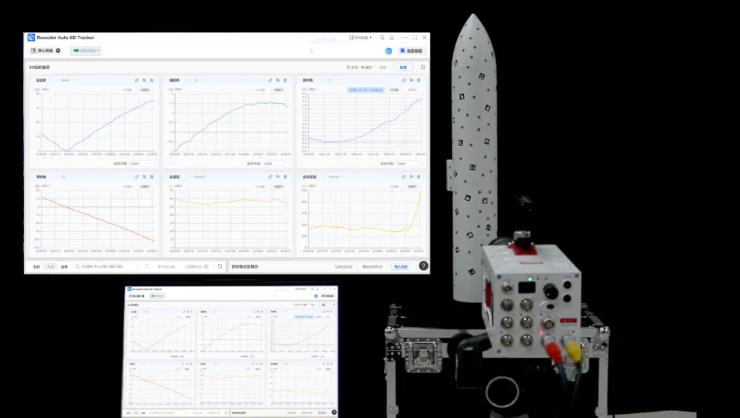

A national metrology institute conducted a performance evaluation of a monocular 6D measurement system developed by Agile Device. The system integrates a Revealer High speed camera with a planar coded target to compute full 6-DOF pose parameters of the motion platform. The goal was to verify accuracy, assess measurement repeatability, and compare performance with other mainstream measurement solutions.

2.1 Objective

Verify the full-parameter measurement capability of the monocular 6D system and compare its results against two alternative approaches:

binocular vision measurement, and

laser displacement + inertial sensors.

2.2 Test Object

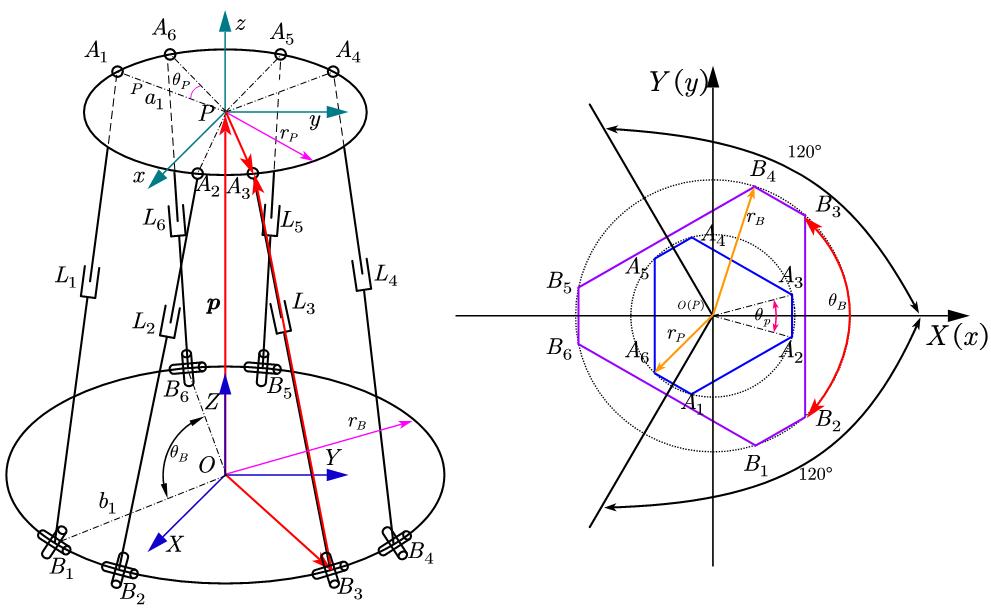

A Stewart-type electromechanical 6-DOF motion platform with:

Position accuracy: 0.7 mm

Angular accuracy: 0.1°

2.3 Measurement Principle (Monocular 6D)

The Revealer High speed camera captures the planar target mounted on the moving platform.

Using:

the known 2D/3D coordinates of feature points (Z=0 plane),

real-time camera intrinsic calibration using a checkerboard pattern,

pixel-level feature extraction,

the system solves for the platform’s six pose parameters (X, Y, Z, Roll, Pitch, Yaw).

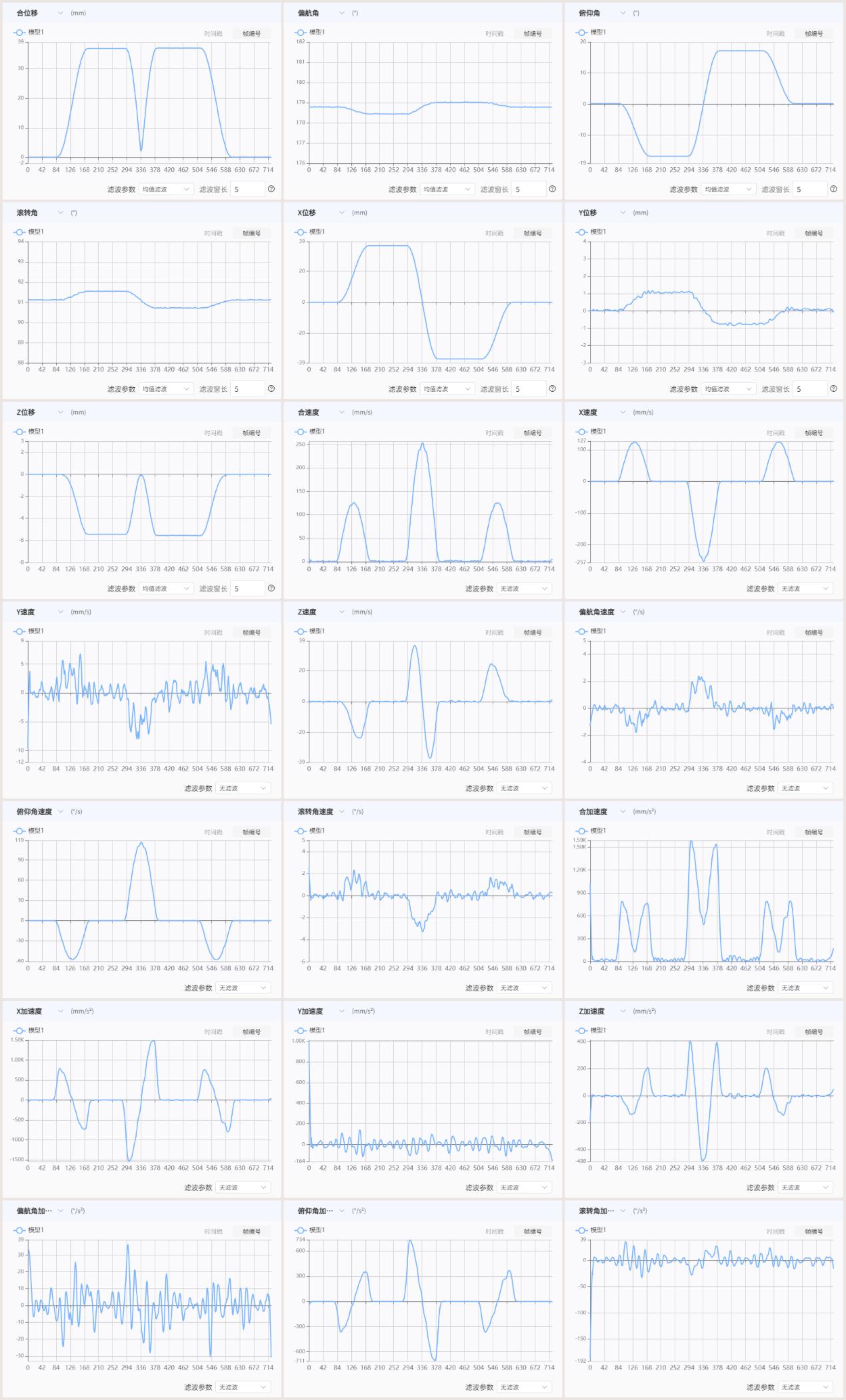

From the recovered trajectory, velocity, acceleration, angular velocity and angular acceleration are further derived.

2.4 Method

A comparative test was performed:

Method | Description |

Monocular 6D (Revealer High speed camera) | Main evaluation target |

Binocular vision | Traditional photogrammetry approach |

Laser + inertial sensors | Conventional displacement + acceleration method |

2.5 Equipment

Revealer monocular 6D measurement system

o 2560×2016 @ 2000 fps High speed camera

o 6-DOF pose-solving software

o Planar cooperation target

Additional devices for binocular and laser-INS comparison.

Step 1: Target Installation

A custom planar target was mounted on the motion platform.

Vernier calipers were used to ensure alignment between the target coordinate system and the platform coordinate system.

Step 2: Camera Placement

A single Revealer High speed camera was placed directly in front of the platform so the full target remained in the field of view.

Step 3: Real-Time Calibration

Camera distortion was calibrated using a checkerboard pattern for accurate monocular reconstruction.

Step 4: Coordinate Alignment

The measurement coordinate frame was aligned with the platform control coordinate frame to ensure parameter consistency.

Step 5: Real-Time Measurement & Playback Mode

During ≤5 Hz low-frequency motions:

The monocular system output real-time 6-DOF data at 50 fps+.

High-frame-rate recording and offline replay analysis were also supported for higher-precision evaluation.

The Revealer monocular 6D measurement system successfully captured the complete 6-DOF motion trajectory of the platform. The measured displacement, angle, velocity, acceleration, and angular acceleration all met calibration-standard requirements.

Cross-validation was performed using:

laser displacement sensors (position), and

inertial sensors (acceleration).

The results show high agreement, confirming that the monocular measurement solution satisfies the accuracy requirements for 6-DOF motion calibration.

This experiment comprehensively verified the feasibility and advantages of the Agile Device Revealer monocular 6D measurement system for six-degree-of-freedom platform testing.

Key Advantages

1. Rapid Deployment in Minutes

Single-camera setup; one operator can complete installation in ~10 minutes.

Much easier to deploy compared with binocular vision systems.

2. Real-Time 50 fps+ Measurement

Enables full-process visualization for low-frequency motions.

Users can adjust test conditions instantly without relying solely on post-processing.

3. Full 18-Parameter Dynamic Output

Includes displacement, angles, velocities, and all first/second derivatives.

4. 40%+ Cost Reduction

Compared with binocular systems, overall cost and maintenance requirements are significantly lower.

5. Sub-Millimeter Accuracy

Position accuracy up to 0.2 mm, attitude accuracy ≤0.2°.

Overall Assessment

The Revealer monocular 6D measurement system from Agile Device is well-suited for metrology-grade 6-DOF motion testing.

It provides a competitive alternative to binocular measurement setups and traditional laser-INS combinations, while also offering strong application potential in scientific research fields including:

ship and marine engineering,

structural vibration and seismic studies,

flight-control system validation,

robotics and autonomous navigation.

Its combination of high accuracy, simple deployment, and reduced cost indicates strong potential for widespread adoption in both academic and industrial environments.