1. Background

Carbon fiber reinforced polymer (CFRP) is widely used in steel structure reinforcement projects due to its excellent mechanical properties and corrosion resistance.

Studies have shown that the interfacial bonding performance between CFRP and steel structures has a great influence on the reinforcement effect, so it is necessary to study the shear slip performance of the CFRP-steel structure interface. The traditional measurement method is to stick strain gauges on the CFRP surface. There will be gaps between the sticking, resulting in discrete measurement results, cumbersome operation, and high cost.

Digital image correlation technology (DIC) is a non-contact optical measurement method that reconstructs the three-dimensional spatial coordinates of the surface points of the object before and after deformation based on the principles of digital image correlation and binocular vision measurement, and then obtains the morphology and deformation information. Compared with strain gauges, it has the characteristics of visualization and full-field continuous dynamic measurement.

2. Experimental introduction

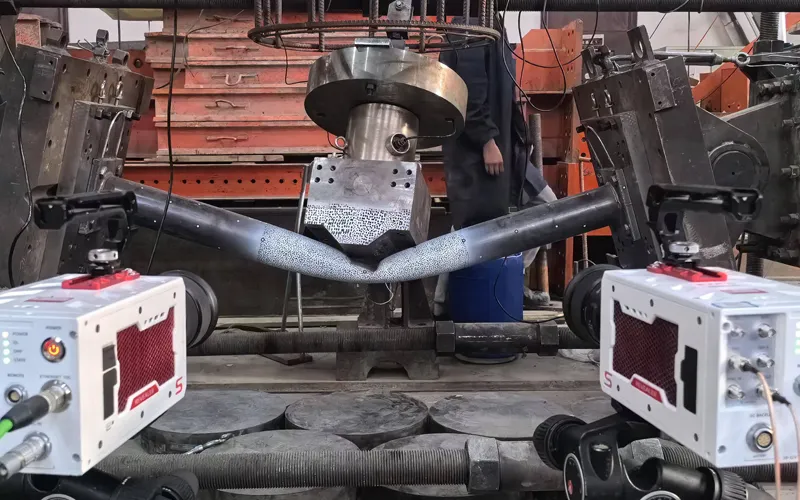

Through double shear tests, the researchers used the Revealer 3D-DIC non-contact strain measurement system to study the shear stress distribution of the CFRP-steel interface under three types of temperature (-10°C, 25°C, 60°C), three types of humidity (30%, 60%, 90%), four types of bonding lengths (40mm, 60mm, 80mm, 100mm), and two types of adhesive layer thicknesses (0.5mm, 1mm), and fitted its shear-slip constitutive relationship using the smoothing method.

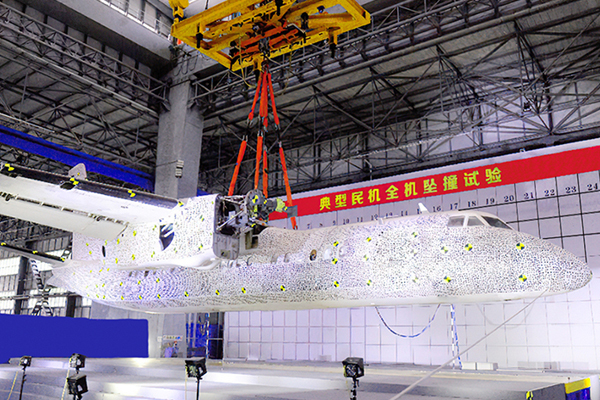

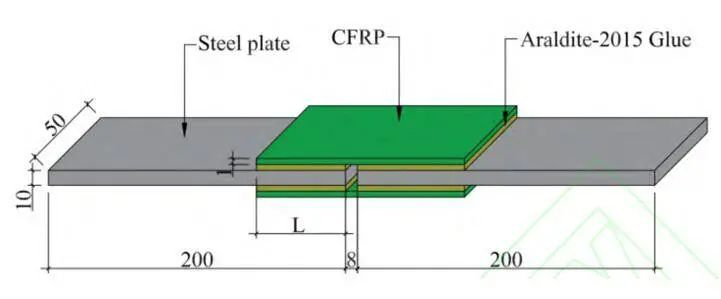

FIG.1 CFRP-steel plate specimen

3. Test procedure

1) According to the four dimensions of 3 types of temperature, 3 types of humidity, 4 types of bonding lengths, and 2 types of adhesive layer thickness, a total of 56 double shear specimens were prepared. The specimens consisted of two steel plates and two CFRP plates bonded by adhesives, as shown in Fig. 1.

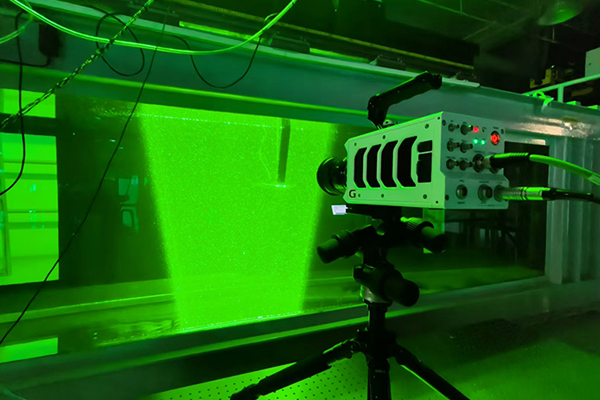

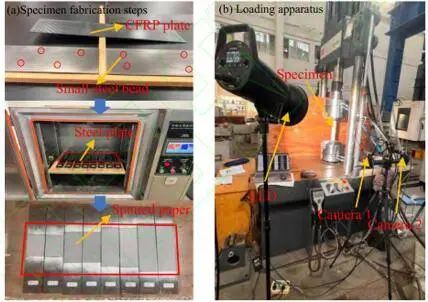

2) The CFRP plate on the side where the strain is to be observed is polished, sprayed with white matte paint, and pasted with speckles, as shown in Fig. 2 (left).

3) Use a 500kN fatigue testing machine for loading, with a rate of 0.2mm/min and a collection frequency of 100Hz.

4) Use the calibration plate to calibrate the specimen and determine the position relationship between the scattered spots on the CFRP plate and the corresponding points in the software.

5) Revealer 3D-DIC non-contact strain measurement system was used to collect data synchronously with the fatigue testing machine at a frequency of 1 Hz to record the strain distribution changes of the CFRP plate during loading, as shown in Fig. 2 (right).

6) After loading, use Revealer 3D-DIC software to calculate the CFRP surface strain data.

FIG. 2 Specimen making procedure and loading device

4. Experimental data

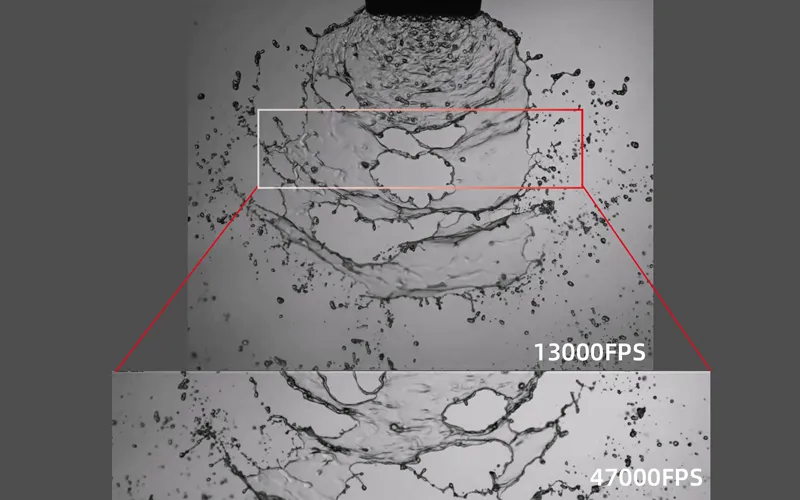

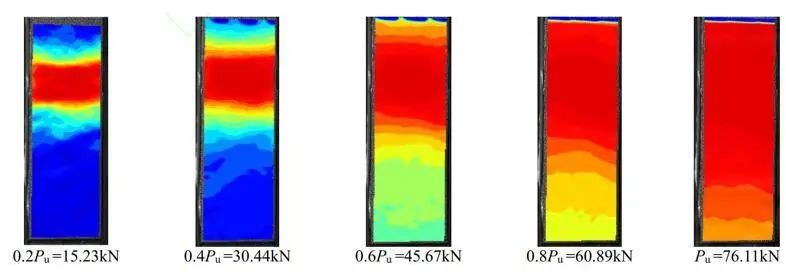

FIG. 3 shows the evolution process of strain distribution and local strain and stress concentration of specimens under different loads under -10°C, 100mm bonding length, 0.5mm adhesive layer thickness and 30% humidity, captured by Revealer 3D-DIC technology under different loads. At first, the strain is mainly concentrated at the loading end, showing a high strain gradient. With the increase of load, the influence region of strain gradually diffused to the free end, indicating that the influence region of shear stress interface gradually increased.

FIG. 3 DIC strain cloud image

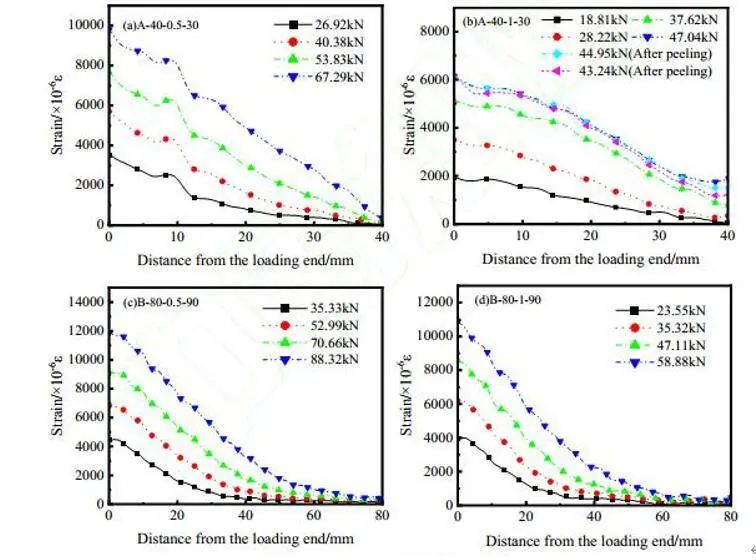

According to the 3D-DIC analysis data, the axial strain data of CFRP during stretching of each specimen can be obtained. Fig. 4 shows the strain distribution curves of four specimens with strain softening in groups A (-10°C) and B (25°C). Based on the peak load Pu, the strain distribution curves of 0.2 Pu, 0.4 Pu, 0.6 Pu, 0.8 Pu, and Pu are drawn in sequence. In the initial loading stage, the axial strain is highly concentrated near the loading end, and the maximum strain increases with the increase of the applied load. When the load reaches a certain value, signs of interface peeling appear, and then the maximum strain tends to stabilize and fluctuates within a certain range.

Fig.4 Axial strain distribution curve of partial strain softening specimen

5. Summary

The study explored the influence mechanism of temperature and humidity curing environment on the interfacial bonding performance of CFRP and steel plate based on double shear test. The influence of temperature, relative humidity, bonding length and adhesive layer thickness on bonding performance was analyzed, and the strain field on the surface of CFRP plate was obtained by 3D-DIC technology. The mechanical properties and failure process of CFRP-steel bonding interface during static load tensile process were analyzed.

The test results show that: the peak bonding load is higher under the curing conditions of 60°C and 60% relative humidity; low temperature and high humidity environment are prone to interface failure; increased temperature and humidity will lead to a decrease in the peak interface shear stress and an increase in slip; an increase in the bonding length helps to disperse regional stress, and a thinner adhesive layer helps to increase the peak interface shear stress and improve stress distribution. The research provides theoretical support and design reference for the engineering application of CFRP reinforced steel structures. Article source: "Effects of temperature and humidity curing environment on the bonding performance of CFRP-steel plate interface"