Original Research by Revealer, powered by Agile Device

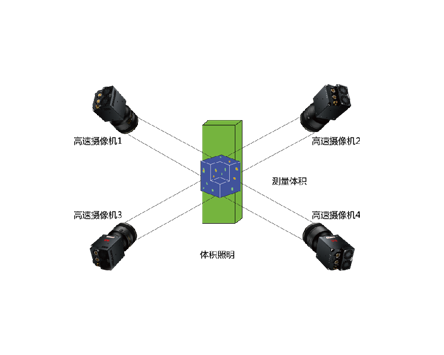

This study demonstrates how combining High Speed Camera technology with Digital Image Correlation (DIC) enables precise dynamic strain measurement in Split Hopkinson Pressure Bar (SHPB) tests. Using Revealer’s NEO25 ultra-high speed cameras and Agile Device’s optical measurement solutions, researchers visualized and quantified the complete microsecond-scale deformation of cement specimens under high strain-rate impact.

High Speed Cameras capture ultra-fast events that conventional imaging systems cannot resolve. In SHPB experiments, they record transient deformation and shock wave propagation in microsecond time frames, allowing real-time observation of elastic, plastic, and failure stages in materials subjected to impact.

Digital Image Correlation (DIC) provides non-contact, full-field strain and displacement measurement, overcoming the limitations of traditional strain gauges that only measure local averages. When combined with high-speed imaging, DIC delivers spatially resolved strain evolution data crucial for understanding material behavior under dynamic loads.

Specimen: Cement disk, Ø50 mm × 25 mm

Equipment:

·Two Revealer NEO25M High Speed Cameras

·Revealer DIC Strain Analysis Software

·Split Hopkinson Pressure Bar (SHPB) system

·Speckle-pattern surface and stereo calibration plate

·Acquisition Rate: 100,000 fps with 10 µs temporal resolution

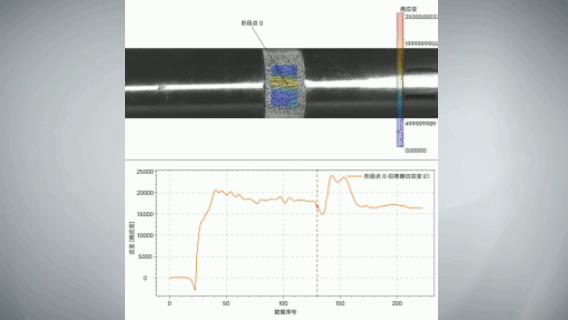

The cameras, supplied by Agile Device, were synchronized to record the specimen’s deformation. DIC software analyzed image sequences to calculate displacement fields and derive Lagrangian strain-time curves.

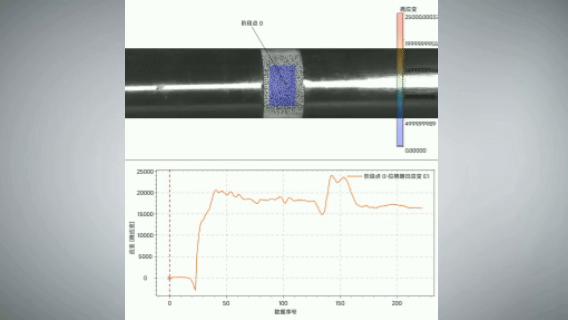

Stage I (190–390 µs | Frames 20–40)

Linear strain growth indicating elastic deformation. The stress wave just reaches the specimen, and stiffness characteristics of the cement material dominate.

Stage II (400–1290 µs | Frames 40–130)

Nonlinear strain oscillation occurs as micro-cracks form and local stiffness decreases. Moderate amplitude implies distributed damage and maintained structural integrity.

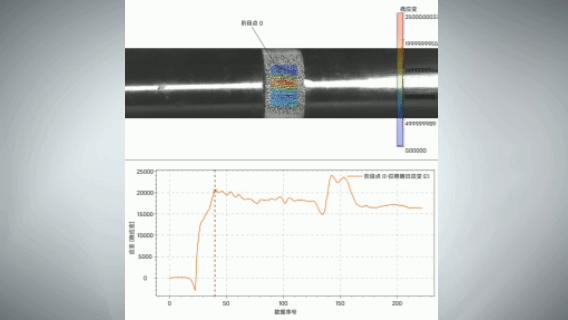

Stage III (1290–1510 µs | Frames 130–152)

A second strain rise due to reflected stress waves re-loading the damaged specimen. Reduced slope indicates stiffness degradation. Post-1510 µs, strain stabilizes as macro-cracks form and the material fails.

I. The Revealer NEO25 High Speed Camera and DIC system successfully captured the full 0–2.2 ms dynamic response of the specimen.

II. DIC-derived strain curves clearly reveal elastic, damage-accumulation, and failure phases.

III. The microsecond-resolution imaging capability identifies critical transient events such as damage initiation and local fracture, providing benchmark data for developing high strain-rate constitutive models.

IV. Agile Device’s optical instrumentation enhances experimental efficiency, repeatability, and calibration precision in high-rate mechanical testing.

Q1: What advantages does a High Speed Camera offer in impact mechanics research?

A1: It captures deformation events at microsecond or even nanosecond timescales, enabling researchers to visualize stress wave propagation and material failure in real time.

Q2: How does Digital Image Correlation (DIC) improve strain measurement accuracy?

A2: DIC provides full-field, non-contact strain mapping, allowing quantitative evaluation of local strain gradients and failure initiation points.

Q3: What industries can benefit from DIC and High Speed Camera integration?

A3: Aerospace materials testing, defense impact analysis, automotive crash research, and energy materials under high-rate loading.

Q4: Who provides the imaging technology used in this SHPB study?

A4: The system was developed by Revealer and supported by Agile Device, specializing in advanced optical and imaging solutions for scientific research.