In fields such as aerospace, automotive collision, and marine and shipbuilding, high-precision dynamic pose measurement of rigid objects is crucial for improving product performance and verifying safety and reliability. Traditional binocular measurement systems suffer from complex deployment and tedious calibration, hindering measurement efficiency. Traditional monocular 6Dof measurement relies on matching explicit features such as corners and edges, which can lead to feature extraction failure in low-texture scenes, insufficient robustness in dynamic measurement scenarios, and the need for manual feature point matching.

The Revealer 6D measuring instrument utilizes advanced dynamic adaptive target detection technology and real-time 3D pose estimation algorithms. Based on a proprietary high-performance deep learning target detection algorithm, it achieves millimeter-level dynamic measurement of rigid object position and pose without manual intervention.

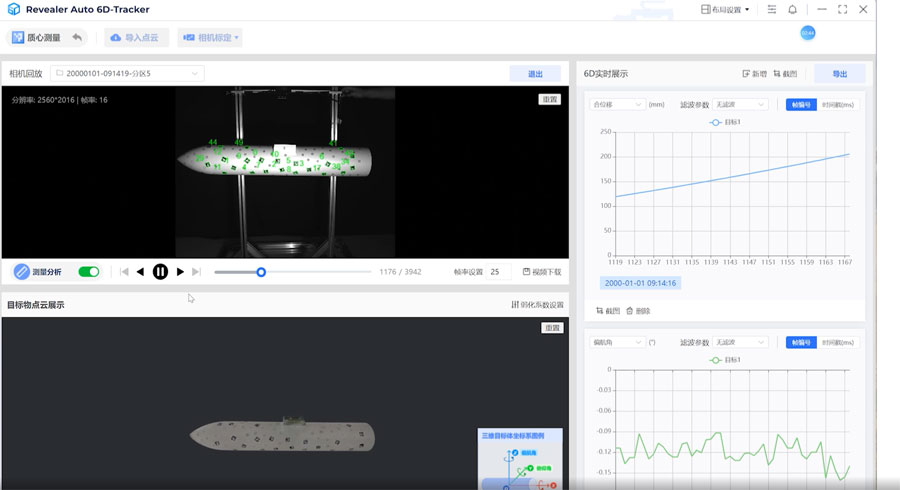

1. Support for Industrial-Grade Point Cloud 3D Reconstruction

To address the pain points of traditional monocular 6Dof measurement methods, which suffer from feature extraction failure and large modeling errors in low-texture, reflective metal surfaces (such as smooth ship hulls and dummy joints), Revealer engineers introduced an industrial-grade 3D scanner equipped with a 5-megapixel high-definition texture camera, which can restore surface features of measured objects at a resolution of 0.05mm. It also integrates an infrared laser projector, which projects a high-contrast artificial target pattern to address the feature extraction challenges of reflective metal objects, enabling high-fidelity 3D modeling of arbitrary rigid bodies.

2. Adopting an intelligent calibration process enables agile deployment and immediate use

Binocular measurement systems typically require a combined calibration of internal and external parameters, relying on manual multi-angle image acquisition. This process is time-consuming and susceptible to environmental interference. Traditional monocular measurement, while eliminating external parameter calibration, still requires complex alignment of the camera's internal target model, making it difficult to meet the demands of agile deployment and rapid testing. The Revealer 6D measuring instrument utilizes proprietary protocols for planes, centroids, and combined targets. This allows for rapid deployment of monocular instruments with only a single internal calibration of the camera, significantly simplifying on-site installation and enabling immediate use. This reduces deployment time from hours to minutes, significantly improving test iteration efficiency.

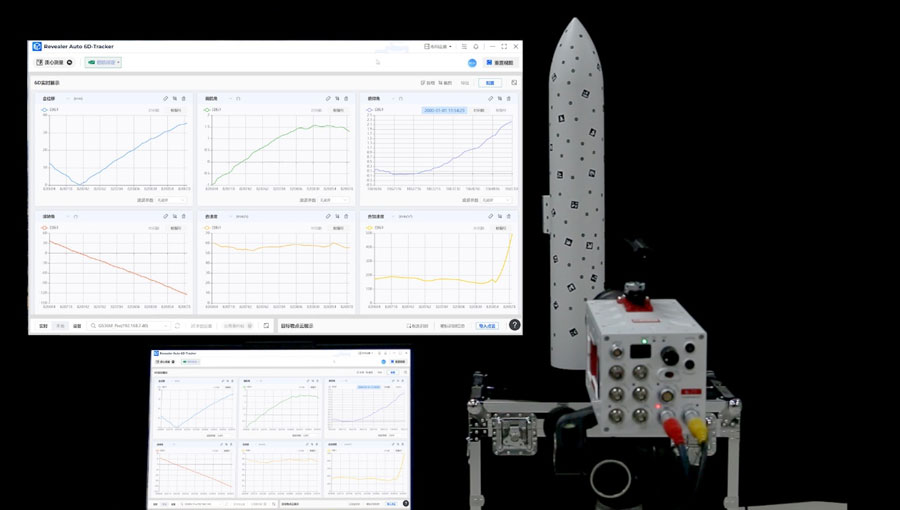

3. Supports real-time 6DoF parameter output at 50+ fps @ 1080P

Traditional measurement systems rely heavily on offline processing and cannot provide real-time pose feedback during testing. This makes it difficult for engineers to adjust parameters or assess test effectiveness in a timely manner, increasing the cost of repeated testing. Revealer provides a real-time 6DoF solution and a visualization solution. Leveraging proprietary advanced dynamic adaptive target detection technology and real-time 3D pose estimation algorithms, combined with high-performance deep learning target detection algorithms, it achieves real-time, high-precision positioning of target objects in 3D space. It also supports real-time generation of 3D pose trajectory cloud maps and 6DoF parameter curves, enabling engineers to adjust test parameters on-site, enabling "measurement-while-viewing" and improving controllability and data insight during testing.

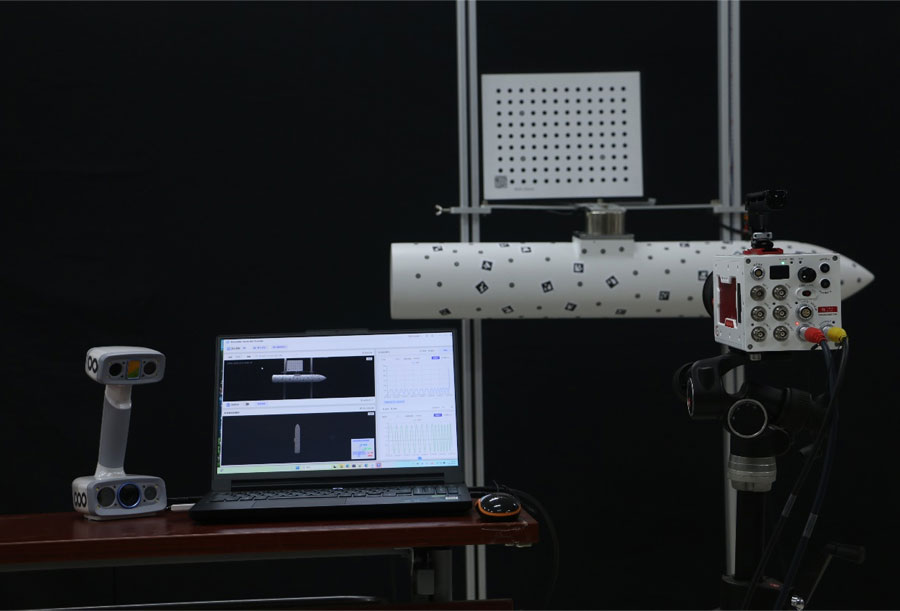

1. Cone-Shaped Object Release Measurement

High-speed conical objects have strong reflective surfaces, making tracking features difficult to extract. During testing, the Revealer 6D measuring instrument used infrared laser target projection to address the issue of strong reflective metal surfaces. Combined with a dynamic adaptive tracking algorithm, it successfully captured a complete 6Dof motion trajectory at the moment of pylon separation, accurately quantifying attitude deviation and trajectory stability during the separation process, providing data support for aircraft release safety assessments.

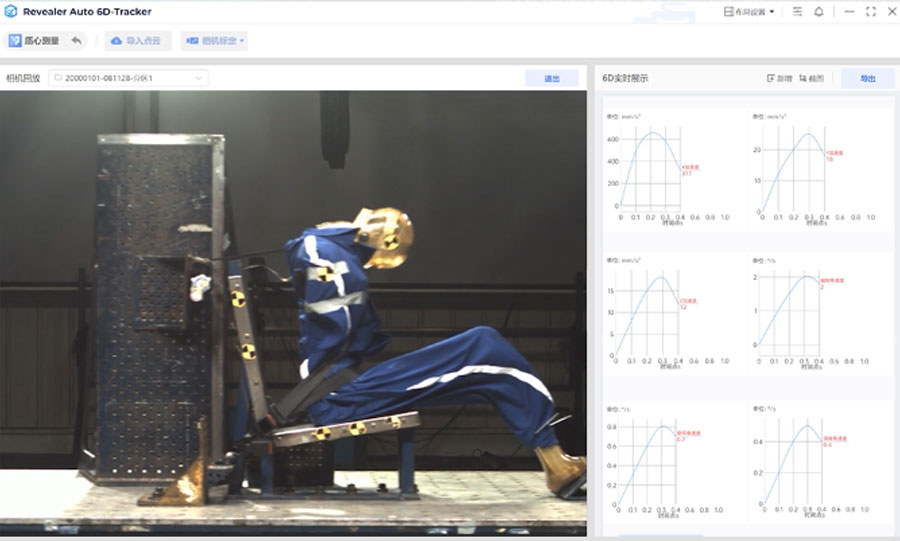

2. Automobile Crash Dummy Testing

During automobile crash dummy testing, real-time tracking of the three-dimensional motion of key areas, such as the dummy's head, neck, and chest, is required to calculate safety indicators such as head injury value and neck injury index. The Revealer 6D measuring instrument tracks key targets on the dummy's head, neck, and chest in real time, outputting displacement, angular velocity, and angular acceleration of each area. Combined with force sensor data, this instrument accurately quantifies damage indicators, improving crash test data integrity and assessment accuracy, and assisting in optimizing vehicle passive safety design.

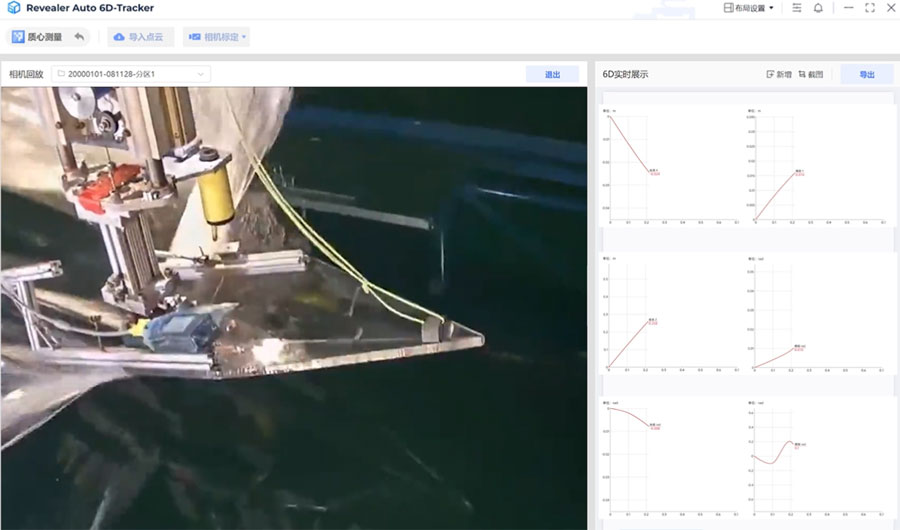

3. Ship Seakeeping Test

In ship model tank tests, it is necessary to measure the hull's six-degree-of-freedom motion response data, including surge, sway, and pitch, under wave excitation. The Revealer 6D measuring instrument replaces traditional mechanical motion sensors, avoiding interference with the flow field. Through long-range target recognition, it enables non-contact, continuous measurement of ship model motion.

The Revealer 6D measuring instrument significantly improves testing efficiency in aerospace, automotive collision, and marine engineering through its innovative combination of technologies: "monocular architecture," "intelligent target," "industrial-grade modeling," and "real-time solution engine." Furthermore, Revealer engineers offer full-process technical solutions for real-time measurement clients, including point cloud reconstruction, coordinate system alignment, and motion solution. The system also supports customized integration with communications, gimbals, cameras, and targets. For more product technical information, please contact us ↓↓↓