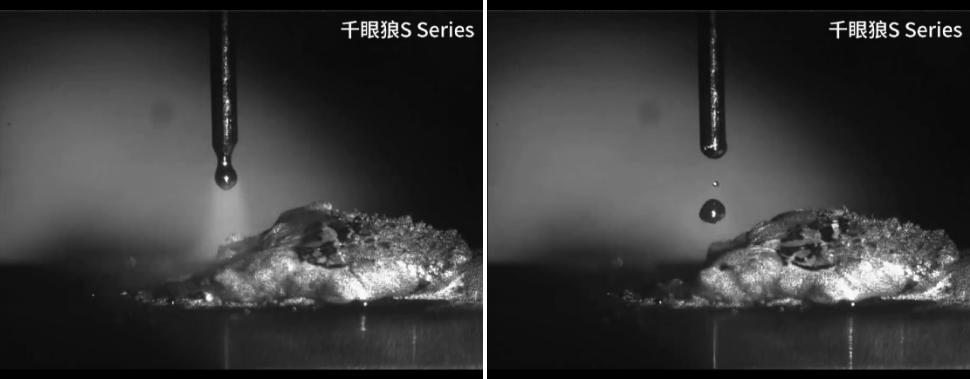

During aluminum-alloy pulsed welding, the transient “full life-cycle” dynamics of a molten droplet—nucleation → necking → breakup (fission) → detachment/fall—are captured using the Revealer S1315M High-Speed Camera. The recorded microsecond-scale evolution provides direct visual evidence for understanding droplet transfer behavior and weld stability.

Aluminum alloys are widely used in aerospace, rail transit, and new-energy vehicles due to their high specific strength, high thermal conductivity, and corrosion resistance. In pulsed welding of aluminum alloys, the droplet transfer frequency and molten pool stability largely determine bead formation quality.

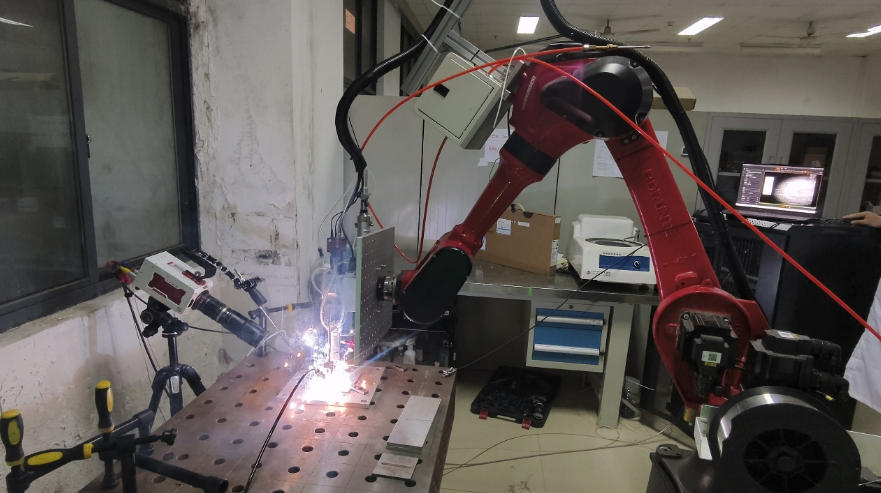

In conventional welding observation, intense radiation from the plasma/arc (arc light) easily obscures key details of the molten pool and droplet transfer. To overcome this, a welding laboratory adopted active pulsed-laser illumination combined with high-speed imaging. With narrowband optical filtering, plasma/arc interference is effectively suppressed, enabling the study of droplet-transfer kinetics and the underlying evolution mechanisms.

2.1 System Configuration

The experiment employs a high-speed camera + pulsed-laser illumination + synchronization control scheme. The goal is to suppress strong arc/plasma glare and improve the visibility of droplet-transfer details.

High-Speed Camera: Revealer S1315M, developed by Agile Device, with key specs of 1280 × 1024 @ 15,000 fps. A filter set is used to attenuate arc radiation (arc light).

Illumination: A pulsed laser is used as an auxiliary light source. A beam expander is applied to reduce the beam divergence angle, increasing illumination power density on the target.

Synchronization Controller: Ensures strict microsecond-level synchronization between laser pulses and camera exposure.

2.2 Test Parameters

Frame rate: 5,000 fps, resolving the droplet-transfer life cycle at a 200 μs time scale.

Frames and duration: Continuous capture of 518 frames, approximately 0.1 s total.

3.1 Overall Observations

At 5,000 fps, the Revealer S1315M decomposes droplet transfer into a 200-μs time-resolved image sequence. The recording covers nine complete droplet-transfer cycles, clearly capturing transient events including necking fracture, primary/secondary droplet fission, and droplet entry into the molten pool.

3.2 A Representative Single Detachment Event (Image-Sequence Interpretation)

Based on a typical droplet-transfer sequence captured by the High-Speed Camera, one representative cycle is interpreted as follows:

I. Droplet Nucleation and Elongation (2400 μs–8000 μs)

Under the thermal effect of the pulsed current, the wire tip begins to melt and an initial droplet nucleates (Fig. 1). Driven by gravity and electromagnetic pinch force, the droplet elongates continuously along the axial direction, forming a preliminary elongated shape (Fig. 2). By examining whether the elongated droplet remains axisymmetric in the captured images, one can assess the stability of the baseline heat input and the likelihood of stable subsequent transfer.

Figure 1 – 3000 μs |

Figure 2 – 7800 μs |

II. Necking and Critical Instability (8000 μs–10400 μs)

At 8000 μs, as the droplet mass continues to increase, the droplet’s center of mass shifts downward, increasing tensile stress on the connecting neck. The droplet exhibits a pronounced dumbbell-shaped necking (Fig. 3). As the neck radius decreases, the local current density rises further; the inward radial electromagnetic force produces a squeezing effect near the droplet root, accelerating the necking into a liquid bridge (Fig. 4).

The formation and lifetime of the liquid bridge observed by the High-Speed Camera are key indicators of droplet-transfer quality. More uniform and symmetric necking tends to produce a cleaner break with fewer satellite droplets. Conversely, eccentric necking more easily generates secondary droplets and may induce fan-shaped lateral scattering.

Figure 3 – 9400 μs |

Figure 4 – 10200 μs |

III. Fracture and Fission (10400 μs–17200 μs)

At 10,600 μs, after the necking reaches a critical radius, the liquid bridge fractures under the combined effects of surface tension and electromagnetic pinch (Fig. 5). At the instant of breakup, both ends of the liquid bridge retract rapidly, releasing surface energy and triggering an energetic instability. This produces a fission structure consisting of a primary droplet + secondary droplet(s). The primary droplet, with larger mass, falls vertically into the molten pool under gravity, while secondary droplets are influenced by lateral plasma/arc forces at breakup and disperse outward along a fan-shaped trajectory (Fig. 6).

Figure 5 – 10600 μs |

Figure 6 – 12000 μs |

IV. Periodic Repetition of the Droplet-Transfer Cycle (17200 μs– )

In the subsequent sequence, the process—droplet growth → necking → liquid-bridge fracture → motion of primary/secondary droplets into the pool—repeats periodically. The repeatability of these cycles is closely related to weld uniformity: if droplet size, breakup location, and entry angle remain consistent across cycles, it indicates stable heat input and typically yields consistent bead width and penetration depth. If fluctuations occur (e.g., droplet-size variation, early/late breakup, increased number of secondary droplets), risks such as bead waviness and increased spatter become more likely.

I. Using the Revealer High-Speed Camera provided by Agile Device together with a pulsed-laser illumination system, this work captured the microsecond-scale evolution of droplet transfer in aluminum-alloy pulsed welding.

II. Results indicate that the transition from dumbbell-shaped necking to fission into primary and secondary droplets is governed by multi-physics competition and coupling among electromagnetic pinch force, surface tension, plasma shear, and gravity.

III. From a process perspective, the axisymmetry during necking and the lateral momentum of secondary droplets at breakup can be used as practical indicators for pulsed-welding stability and spatter tendency. High-speed camera observation provides visual evidence to support pulse waveform optimization, spatter suppression, and improved weld-bead consistency.