In the clean steel production process, the tundish serves as a key equipment between molten steel refining and continuous casting. Its internal flow field directly affects the efficiency of inclusion removal and the purity of molten steel. Traditional flow control devices are prone to problems such as increased residual steel and erosion of refractory materials, and their efficiency in removing fine inclusions is limited. Gas stirring technologies like gas curtains have emerged as a new direction, but they face challenges such as difficulty in controlling bubble size and insufficient flow field optimization. The research team from Taiyuan University of Technology focused on a single-strand tundish without flow control devices, innovatively proposing a sidewall gas blowing scheme (right sidewall/front sidewall). Combined with high-speed cameras and a Particle Image Velocimetry (PIV) system, they conducted visual observations on the flow field characteristics under right sidewall and front sidewall gas blowing conditions, and used the results to verify the reliability of the CFD model. The detailed research results were published in Steel Research International (2024, 95, 2400037) titled "Physical and Numerical Study on Right Side and Front Side Gas Blowing at Walls in a Single-Strand Tundish".

I. Physical Model Design

The experiment adopted a water model device with a geometric scale of 1:5 to simulate the actual tundish. The working medium was deionized water, and hollow glass microspheres (with a particle size of approximately 50 μm) with a density close to that of water were selected as tracer particles. Gas was controlled by a micro-flow meter and injected through small holes in the wall to simulate the industrial argon purging process.

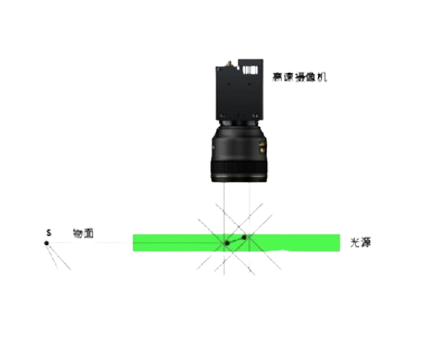

II. Flow Field Measurement Equipment (see Figure 1)

A Revealer high-speed camera provided by HF Agile Device Co.,Ltd was used, with a resolution of 1920×1080 @2000fps, to capture the movement trajectory of tracer particles.

A continuous-wave laser, with a wavelength of 532 nm and a power of 10 W, was used to generate a sheet light source with a thickness of 1 mm and a divergence angle of 15°.

Revealer's self-developed flow field measurement PIV software RFlow was used to extract the displacement components of particles in adjacent frames, calculate the velocity vector distribution, and generate flow field velocity vector diagrams.

Figure 1

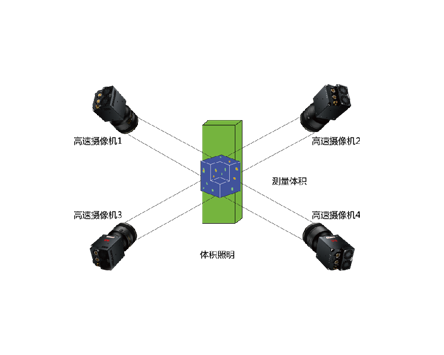

This study focused on three core verification objects: "empty tundish (Scheme N), right sidewall gas blowing (Scheme R1), and front sidewall gas blowing (Scheme F2)". The reliability of the numerical model was verified by comparing the measured data from the PIV system with the CFD simulation results. The detailed steps are as follows:

I. Stabilize the Water Model, Calibrate, and Add Tracer Particles

Adjust the water flow in the water model to a stable state, then introduce tracer particles with a density close to that of water. Perform grid calibration in static water to determine the corresponding relationship between the field of view range and the coordinate system. Turn on the water pump and gas supply, and wait for the flow to stabilize.

II. Conduct PIV Flow Field Measurement

Start the 532 nm laser sheet light source to illuminate the measurement area in the middle of the tundish. Simultaneously turn on the high-speed camera to continuously shoot for 3 seconds at a frame rate of 400 fps, obtaining the sequence of movement images of tracer particles. Then use Revealer's PIV software to perform cross-frame analysis on the images, extract particle displacement data, calculate, and generate flow field vector diagrams.

III. Model Verification and Comparison

Establish a CFD model based on the geometric parameters of the water model. The Euler-Euler method was used to simulate the gas-liquid two-phase flow. The turbulence model for the continuous phase (water) was the realizable k-ε two-layer model (RKE-2L), and the discrete phase (air) adopted the Issa turbulence response model. Quantitatively compare the PIV-measured velocity field with the CFD simulation results, focusing on verifying the consistency of vortex structures and velocity distributions under three key schemes: no gas blowing (Scheme N, empty tundish), right sidewall gas blowing (Scheme R1), and front sidewall gas blowing (Scheme F2).

The value of the Particle Image Velocimetry (PIV) instrument lies in providing a measured benchmark for the CFD model, verifying the CFD model from three dimensions: vortex structure, flow velocity distribution, and flow pattern consistency.

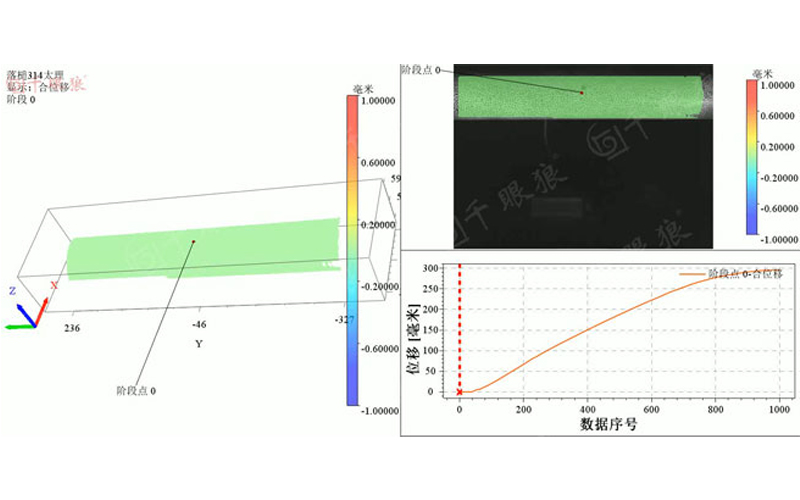

I. Scheme N (Empty Tundish, i.e., Benchmark Condition without Gas Blowing)

This scheme is for the verification of the basic flow field. PIV measurement results show that there are two counterclockwise vortices in the middle of the tundish in the velocity vector diagram. The velocity vector distribution obtained by CFD simulation is highly consistent with the PIV measurement results—both in the positions of the two counterclockwise vortices and the velocity amplitude in the vortex area, which is highly consistent with the PIV measured value. This indicates that the basic model can accurately reflect the main flow pattern in the bare tundish (see Figure 2 for details).

Figure 2

II. Scheme R1 (i.e., Right Sidewall Gas Blowing Condition)

This scheme is for the verification of local vortex structures. PIV measurement results show that after right sidewall gas blowing, a large counterclockwise main vortex penetrating the middle area is induced, and the upward gas flow drives the surrounding liquid to form a circulation structure. The deviation between the velocity in the central area of the main vortex measured by the PIV system and the CFD predicted value is less than 8%. The spatial distribution of velocity direction and intensity is in good consistency, verifying that the CFD model can accurately capture the "reconstruction effect of sidewall gas blowing on the vortex structure", including the number, position of vortices, and local flow velocity changes. It can be used to analyze the optimization effect of right sidewall gas blowing on the local flow field (see Figure 3 for details).

Figure 3

III. Scheme F2 (i.e., Front Sidewall Gas Blowing Scheme)

This scheme is for the verification of complex flow patterns. PIV measurement results show that after front sidewall gas blowing, the flow field presents a reverse double-vortex structure: a counterclockwise vortex is on the side close to the protective cover, and a clockwise vortex is on the side close to the outlet. The distance between the two vortices is smaller than that in Scheme N, and they are symmetrically distributed on both sides of the gas column. The reverse double-vortex structure simulated by CFD is completely consistent with the PIV measurement; the rotation direction and distance of the vortices are accurately reproduced. The error between the calculated flow velocity in the vortex on the protective cover side and the PIV measured value is less than 2%, and the flow velocity deviation of the vortex on the outlet side is less than 3%. This indicates that the CFD model can accurately simulate the "complex spiral vortex formed by front sidewall gas blowing", providing a reliable numerical tool for the optimization analysis of the entire flow field (see Figure 4 for details).

Figure 4

I. PIV Measurement Data Provides Key Verification for the CFD Model

Through direct comparison of the velocity vectors of Schemes N, R1, and F2, it is confirmed that the current CFD model can truly reflect the vortex structures, velocity distributions, and flow directions under different gas blowing methods, with the average velocity error controlled within 10%.

II. Scheme F2 is the Optimal Scheme

PIV-CFD collaborative analysis shows that the large spiral vortex formed in the flow field can stir the fluid in the entire tundish, with a dead zone volume of only 39.68%. Additionally, the surface flow is enhanced, which is conducive to the floating of inclusions. Compared with right sidewall gas blowing, the flow field uniformity is better, and at the same time, it avoids the slag entrainment risk caused by high flow rate and high-position gas blowing.

In the clean steel production process, the use of visual PIV technology solves the problem of "inability to directly observe the high-temperature molten steel flow field". Through the collaboration of PIV measurement and CFD model, the flow field regulation mechanism of tundish sidewall gas blowing is analyzed, helping technicians screen out the optimal process scheme and providing a replicable technical path for the flow field optimization of clean steel tundishes.