1. Research background

Due to its excellent antibacterial properties, thermal and electrical conductivity, pure copper is a promising coating material and is widely used in the fields of medical equipment, nuclear industry and new energy vehicles.

Different laser wavelengths have an important impact on pure copper laser cladding. Pure copper materials have a high reflectivity for infrared lasers. It is difficult to form a stable molten pool in the initial stage of welding and is prone to defects such as spatter and keyholes, which affects the welding quality and efficiency. Therefore, blue laser cladding technology with low reflectivity has become a research hotspot for preparing pure copper coating technology.

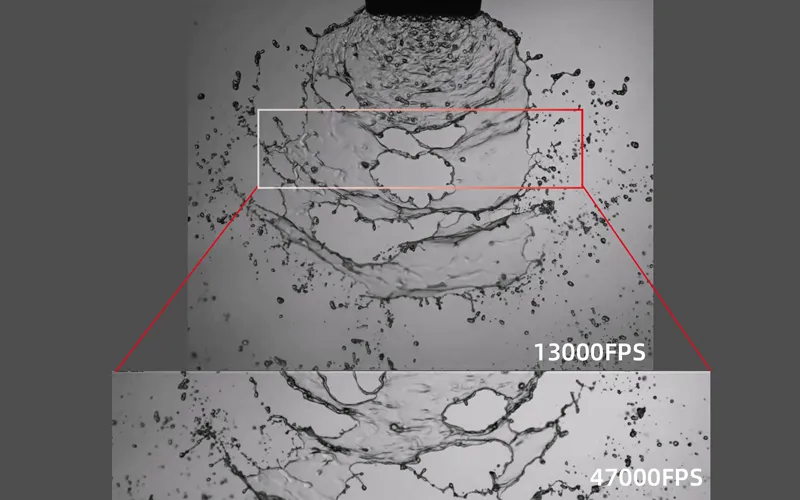

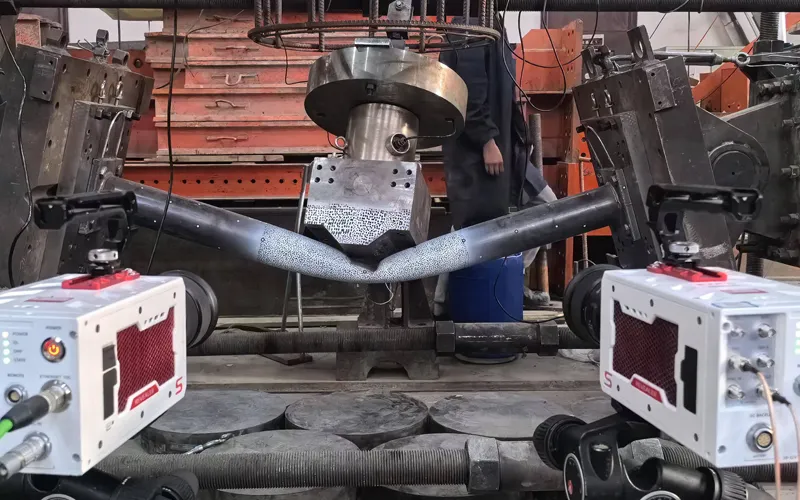

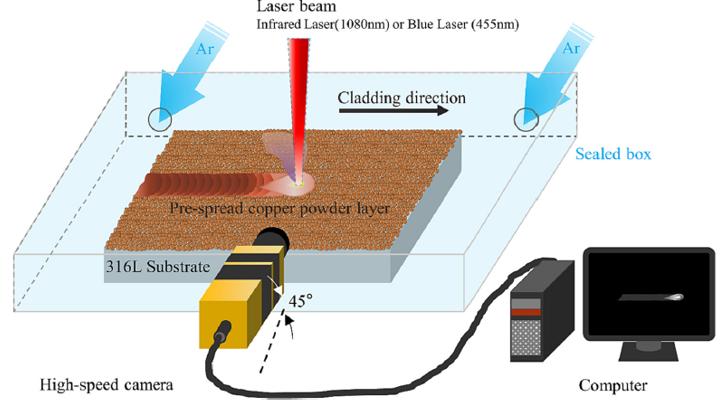

Researchers from Guangxi University adopted a visual experiment method based on high-speed camera technology (Figure 2), using lasers of different wavelengths and scanning speeds to coat copper powder on 316L stainless steel substrates, and used high-speed cameras to study its impact on droplet splash and powder splash. Further research on the macro-microstructure, element distribution and mechanical properties of the coating can provide theoretical guidance for the preparation of pure copper coatings.

2. Visualized experimental instruments and experimental conditions

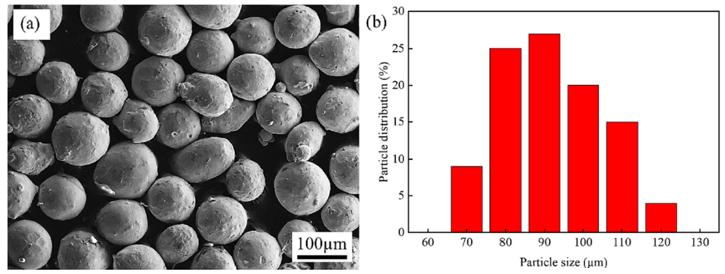

1) 316L stainless steel is used as the base, and the coating is made of copper powder with a content of 99.7% and a particle size of 70~120µm (Figure 1).

Figure 1 Copper powder

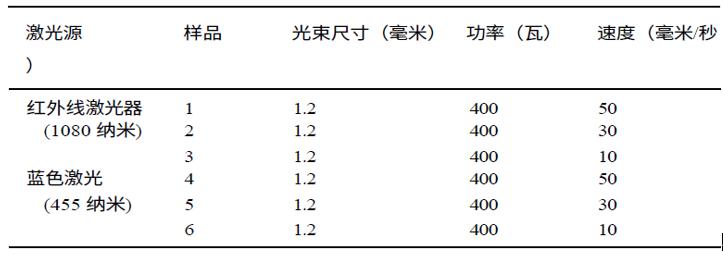

2) Infrared fiber laser with a wavelength of 1080nm and blue laser with a wavelength of 455nm, three sets of experiments are designed according to the laser cladding speed for comparison (see Table 1).

Table 1 Experimental conditions of laser cladding

3) Revealer high-speed camera (Revealer X213M), observing with 1280×1024 @10000fps parameters.

4) 808, 40WD IO laser, used to reduce the impact of laser radiation reflection and vapor plume.

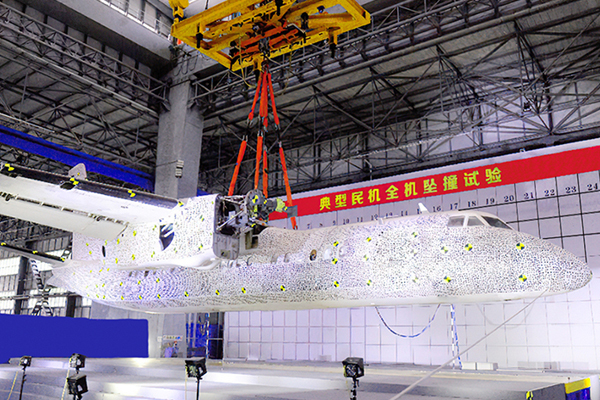

Figure 2 Visualized experimental device

3. High-speed camera visualization experiment part

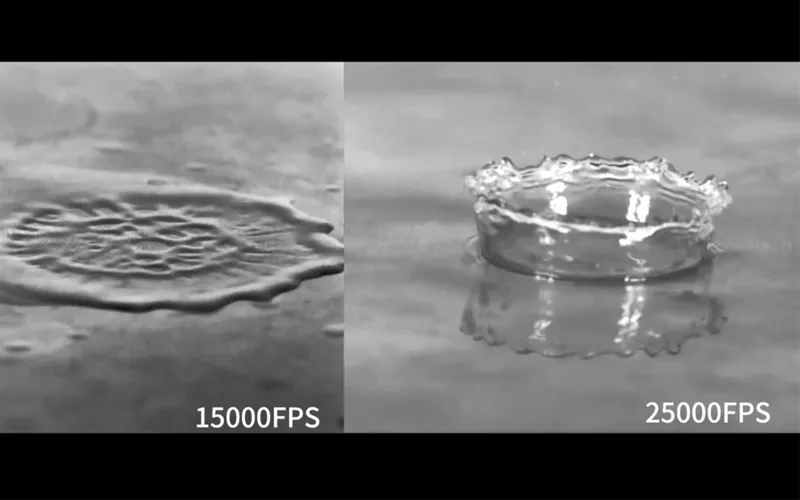

The sputtering process of the molten pool under different laser wavelengths captured by the Revealer high-speed camera is shown in Figure 3. The analysis is as follows:

1) There are two types of movement of spray spatter. One is "droplet splash" which is opposite to the coating processing direction. It is caused by Marangoni flow and steam recoil pressure. During the splash process, spherical droplets are formed after cooling. . The other is "powder splash" along the direction of laser cladding, which comes from melted or unmelted metal near the laser beam and splashes outward under the extrusion of recoil pressure.

2) Through comparison, it is found that compared with blue laser, infrared laser cladding produces a large amount of spatter in the powder layer. When the scanning speed is 50mm/s, the sputtering objects are mainly powder splashing. This is because when the scanning speed is 50mm/s, the laser input heat is limited, the copper material has a high reflectivity under infrared laser, and the energy absorbed by the powder is not enough to support its melting, resulting in poor stability of the molten pool. As the scanning speed decreases, the sputtering changes from powder splashing to droplet splashing. The increase in heat causes an increase in metal vapor above the molten pool, forming downward recoil pressure.

3) When the temperature of pure copper material reaches the melting point, the absorption rate of infrared laser by copper will change rapidly, causing the instability of the molten pool to increase. Since the infrared laser is a Gaussian heat source, the high energy intensity in the center of the heat source causes the material to quickly rise to the boiling point after reaching the melting point, causing local keyhole phenomena in the coating, exacerbating the instability of the molten pool, and the droplets are easily accelerated by the metal vapor and move backward. Spray out, therefore, infrared laser cladding of pure copper materials is more likely to produce spatter.

4) Under blue-light laser cladding, when the scanning speed is 50mm/s, the splash is mainly "powder sputtering". As the scanning speed decreases, the powder splashing gradually transforms into droplet splashing. Pure copper material under blue light laser has a high absorption rate, melts quickly under the laser beam, and immediately wets and spreads on the substrate. Since the absorption rate of pure copper material under blue laser does not increase significantly as the material melts, the melting process is stable and there is less spatter.

5) After laser cladding, the macroscopic morphology, microstructure and microhardness of the coating were further studied by wire-cut EDM samples: the surface macromorphology of the coating was observed using a depth-of-field optical microscope, and the cross-section of the coating was studied using an optical microscope. The microstructure and element distribution of the coating were studied using a scanning electron microscope, and the microhardness distribution of the coating under different laser parameters was measured using a microhardness tester.