Original Research by Revealer | Supported by Agile Device

Executive Summary: PIV Camera Performance in Spray Flow Analysis

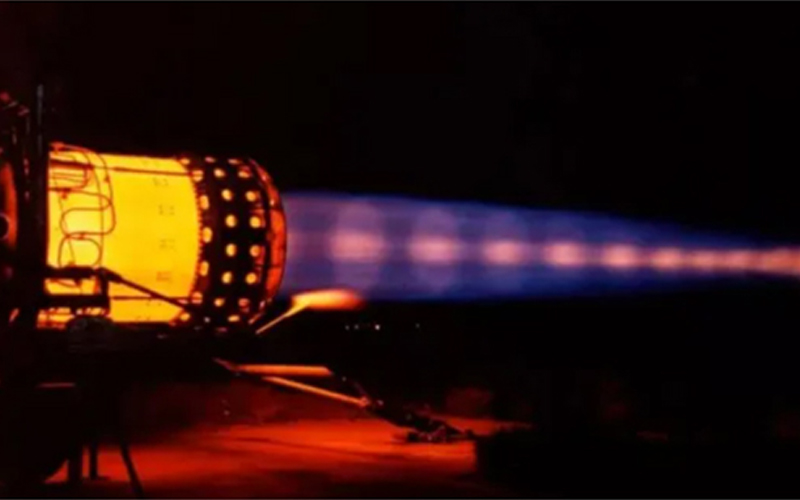

This technical case study demonstrates how the Revealer NEO25 PIV camera successfully measures high-speed spray flows using Particle Image Velocimetry (PIV) technology. The high-sensitivity camera captures droplets at 25,000 fps, enabling detailed analysis of spray velocity fields, turbulence characteristics, and droplet dynamics even with low-power laser illumination.

Spray systems play a vital role in industrial cooling, fire safety, and chemical reaction control. The internal geometry of the nozzle — including contraction angle and outlet diameter — directly affects droplet size distribution, spray velocity, and coverage uniformity.

Particle Image Velocimetry (PIV) has become a cornerstone technique for non-intrusive, full-field velocity measurement in fluid dynamics. However, traditional high speed cameras often struggle to capture fast-moving droplets in spray fields due to limited sensitivity and temporal resolution. The challenge intensifies under strong light scattering, where sub-millimeter droplets require exceptionally high signal-to-noise imaging, and low-power lasers provide insufficient illumination.

To overcome these constraints, researchers employed a high-sensitivity High Speed Camera (Revealer NEO25) from Agile Device, paired with a low-power continuous laser and Revealer Rflow4 particle imaging velocimetry (PIV) software. This configuration achieved high-quality visualization and quantitative analysis of spray flow fields at an economical cost.

2.1 Experimental Conditions

Spray medium: Water-based droplets, 100–200 μm diameter range

Injection velocity: Approximately 20 m/s

Target setup: Simulated single-nozzle spray apparatus

2.2 Equipment Configuration

Imaging system: Revealer NEO25 High-Sensitivity High Speed Camera (1280×1024 @ 25,000 fps)

Laser source: 532 nm continuous laser, 10 W power

Software: Revealer Rflow4 Particle Image Velocimetry (PIV) package

2.3 Experimental Procedure

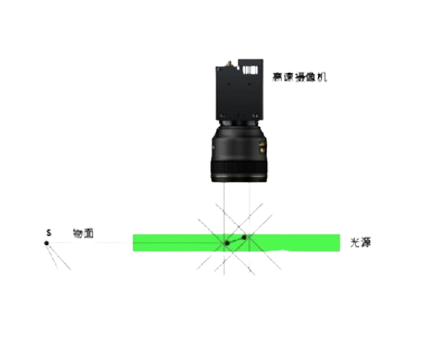

I. The PIV system was precisely aligned and calibrated. The Revealer NEO25 High Speed Camera equipped with a 50 mm f/1.4 prime lens was oriented perpendicular to the laser sheet plane to ensure accurate imaging geometry.

II. The acquisition frame rate was set to 10,000 fps, allowing effective particle displacement tracking within 100 μs frame intervals for cross-correlation algorithms.

III. Exposure time was 20 μs, shorter than the frame interval, to freeze droplet motion and prevent streaking. The NEO25’s superior sensitivity compensated for reduced light exposure, maintaining image brightness and clarity.

IV.Captured PIV image sequences were processed through multi-pass vector analysis (from 64×64 to 32×32 pixels) to compute instantaneous velocity fields. Outlier vectors were corrected via median filtering.

V.From the ensemble of instantaneous fields, time-averaged velocity maps were generated to analyze spray structure and turbulence characteristics.

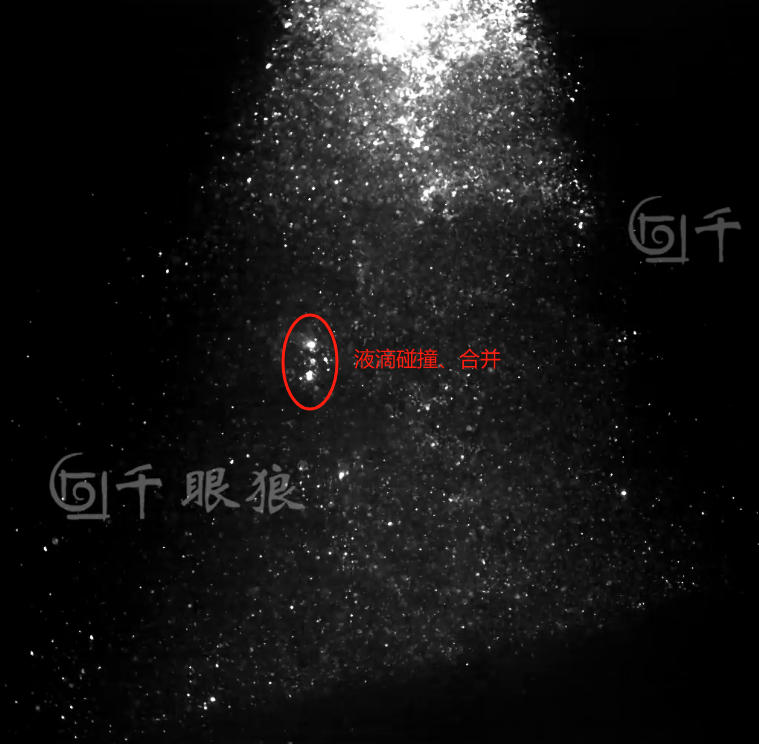

3.1 Original Spray Imaging

The Revealer NEO25 High Speed Camera successfully visualized droplet motion within vortical structures. In the shear-dominated mixing zones, droplets experienced collision, coalescence, and secondary breakup — processes that define droplet size distribution and spray efficiency.

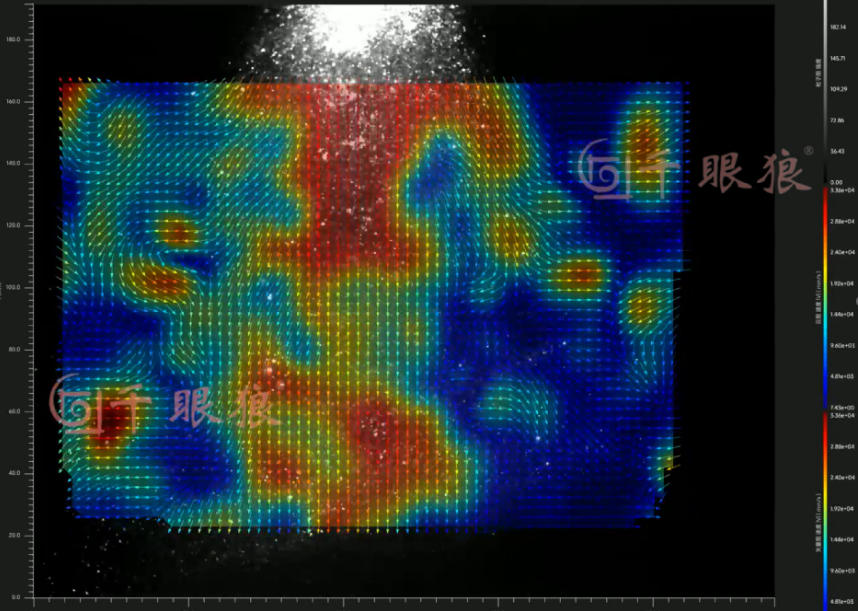

3.2 Instantaneous Velocity Fields

Instantaneous velocity maps revealed a non-axisymmetric jet core characterized by pulsation and curvature, indicating inherent flow instability. Corresponding vorticity fields showed multiple interacting vortices formed within the shear layer between the jet and ambient air. These vortices evolved through roll-up, pairing, merging, and dissipation, enhancing momentum and mass exchange between droplets and air.

3.3 Time-Averaged Velocity Fields

The time-averaged velocity contours exhibited a clear jet structure divided into core, transition, and edge regions. The mean velocity decayed along the axial direction due to entrainment effects and displayed a Gaussian radial distribution. These results quantitatively characterized the coverage range and velocity attenuation of the spray, aligning well with design expectations.

This study demonstrates that the Revealer NEO25 High Speed Camera, integrated with 2D2C PIV and powered by Agile Device, enables precise and cost-effective measurement of high-speed spray flow fields even under low-power laser illumination. Key findings include:

I.The instantaneous velocity maps reveal the unsteady, turbulent nature of spray jets, providing direct evidence for analyzing coherent flow structures and instability mechanisms.

II.The time-averaged fields confirm nozzle performance, spray uniformity, and flow decay behavior, supporting system design validation.

III.The high sensitivity of the NEO25 compensates for limited laser power, achieving clear particle image velocity (PIV) imaging under low illumination — offering a reliable, scalable solution for spray system optimization and cost-efficient experimental setups.