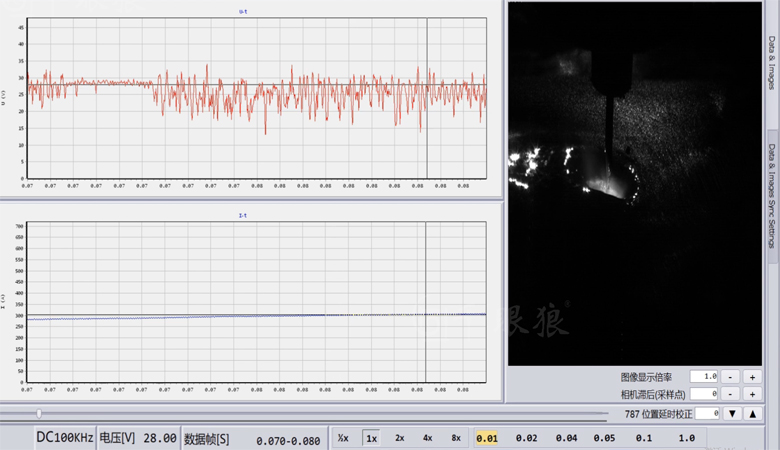

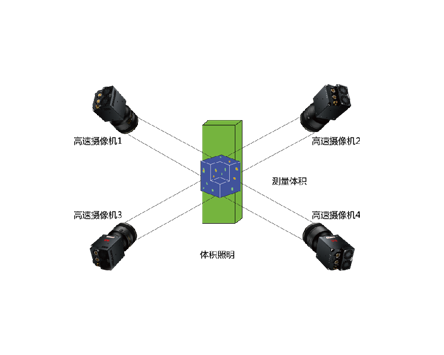

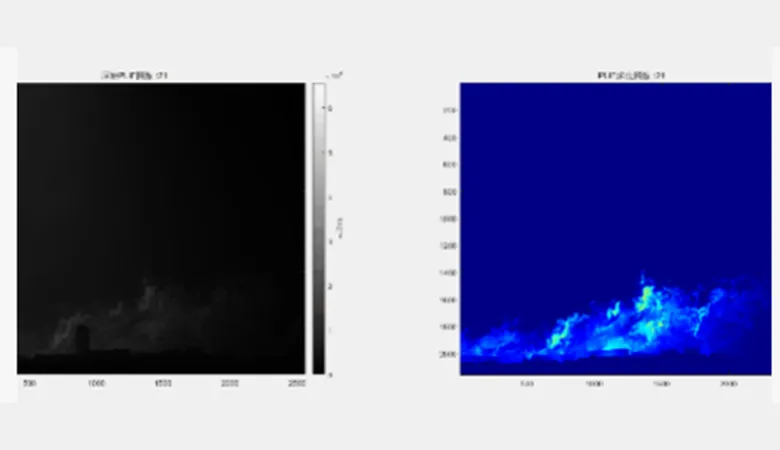

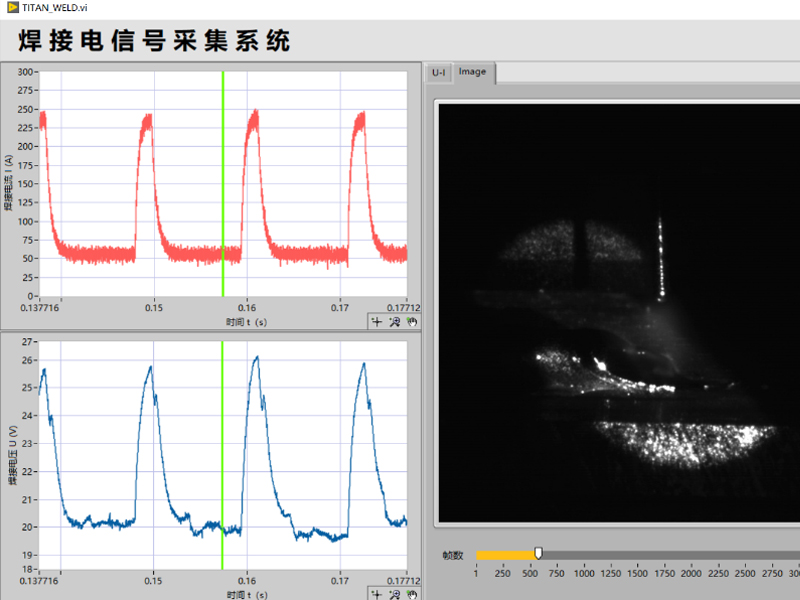

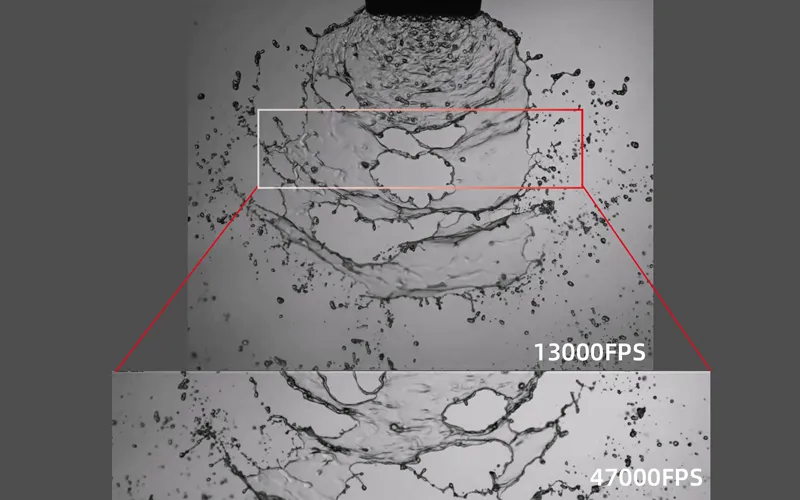

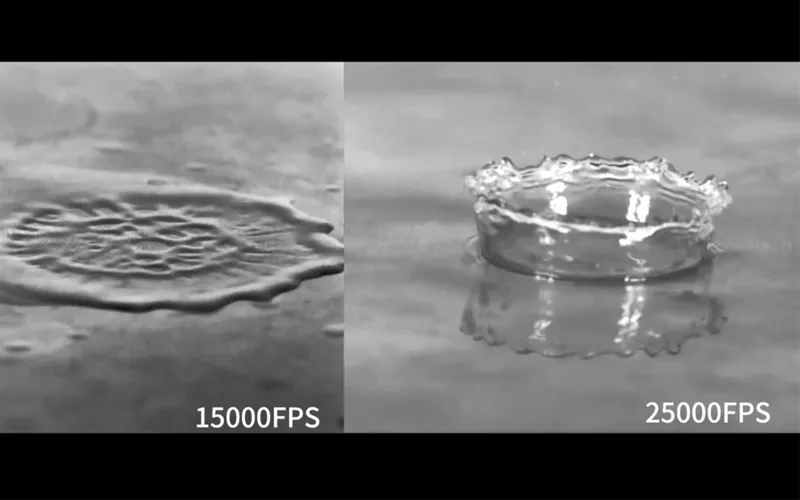

· Dynamic behavior and minor deformations of high-speed moving components, molten pool dynamics, weld formation process, and spatter behavior (captured using high-speed cameras).

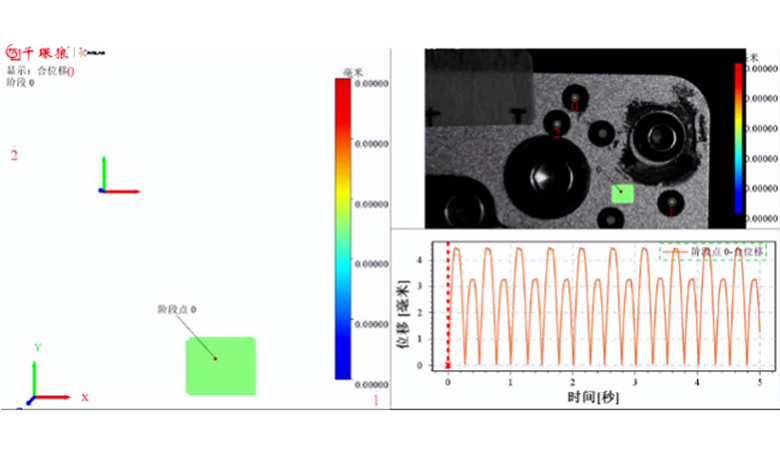

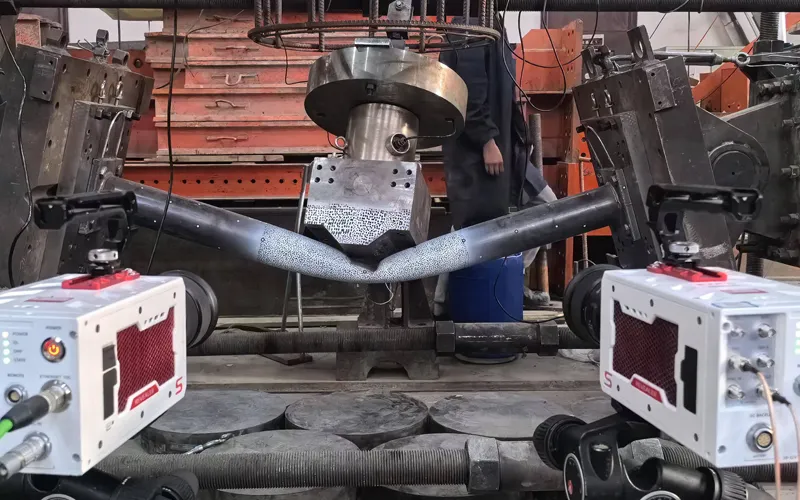

· Strain and displacement distribution of workpieces under load (measured using Digital Image Correlation (DIC) systems).