This study performs quantitative reconstruction and multidimensional visualization analysis of the 3D velocity field and transient vortex structures in the near-field of a supersonic combustion flame nozzle based on 3D3C Particle Image Velocimetry (PIV) tomographic volumetric measurement technology. The experiment utilizes the Revealer 3D3C-Particle Image Velocimetry (PIV) system independently developed by Agile Device, integrated with multiple Revealer High Speed Cameras. This setup achieves stable imaging and high-precision flow field inversion under challenging conditions characterized by intense flame self-luminescence, high temperatures, and strong turbulence.

Combustion flame flows are prevalent in aero-engine combustion chambers, scramjets, rocket propulsion systems, and high-enthalpy combustion test facilities. Their flow characteristics typically involve high temperatures, high radiation, steep velocity gradients, and strong turbulence coupling. In the near-field of the nozzle, phenomena such as flame expansion, shear layer development, reflux entrainment, and vortex structure evolution are highly coupled, forming significant 3D unsteady flow structures. Since these structures directly determine combustion efficiency, stability, and structural safety, obtaining quantitative 3D velocity distributions and vortex information is fundamental for combustion mechanism research and engineering optimization.

In such extreme conditions, traditional point-based or 2D flow diagnostics fail to meet requirements for spatial integrity and quantitative accuracy. The combination of High Speed Cameras and Particle Image Velocimetry (PIV) technology enables non-intrusive, full-field, transient, and high-resolution flow measurement, becoming a core experimental tool in combustion flame research.

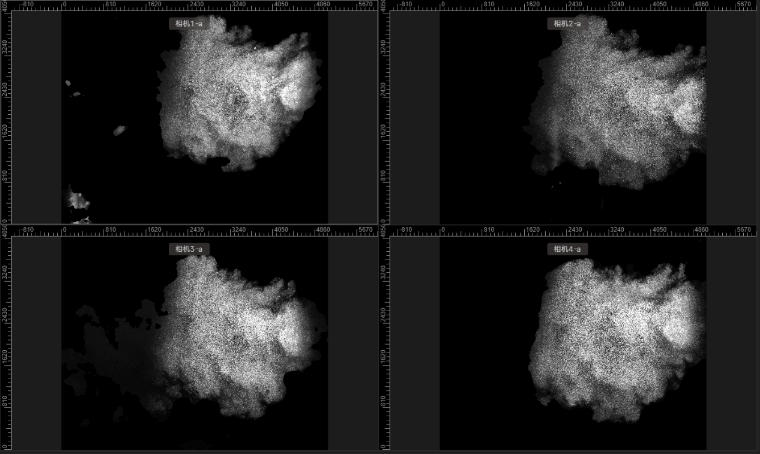

This experiment employs a 3D3C Particle Image Velocimetry (PIV) volumetric measurement scheme for the quantitative characterization of 3D flow structures. Agile Device provided the integrated hardware and software solution. The system's core is built on a volumetric imaging architecture using four Revealer PIV-ready High Speed Cameras (G2100M) (Table 1). It captures tracer particle scattering images from multiple synchronized perspectives and uses tomographic reconstruction and three-component velocity inversion algorithms to simultaneously obtain volumetric velocity fields and vortex structures.

Table 1: Key Parameters of Revealer High Speed Camera G2100M

Resolution: 5120 × 4096

Full Frame Rate: 36 fps

Bit Depth: 12 Bit

Pixel Size: 4.5 μm

Peak QE: 63%

PIV Inter-frame Time: 200 ns

Data Interface: CXP-12 (Real-time transmission)

For illumination, a low-frequency, high-energy double-pulse laser is used to meet SNR requirements in high-temperature environments. Micron-sized alumina particles are chosen as tracer particles due to their high-temperature resistance and flow-following capability. Data processing is handled by Revealer's proprietary PIV post-processing software, enabling volume self-calibration, particle reconstruction, and multidimensional visualization (slices, isosurfaces, and streamlines).

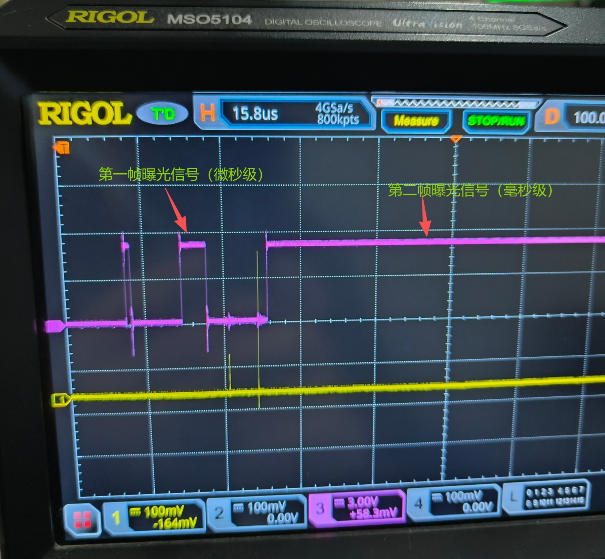

The primary challenge for a High Speed Camera in combustion research is not just the frame rate, but controlling the imaging signal-to-noise ratio (SNR) and maintaining exposure consistency across frames under intense flame self-luminescence. In traditional PIV straddling modes, the second frame's exposure time is often significantly longer than the first(Fig.1). Intense chemical self-luminescence can easily drown out the particle scattering signal in the second frame, even with band-pass filters, leading to systematic errors in velocity inversion.

Fig.1

To address imaging distortion from flame luminescence, the Revealer 3D3C-PIV system introduces a high-speed liquid crystal shutter(Fig.2). Through a custom synchronization strategy, the shutter switches from transparent to opaque within microseconds. This compresses the effective exposure time of the second PIV frame to match the first. This solution suppresses interference from the time dimension, significantly improving the SNR and brightness consistency between frames.

Fig.2

The experiment follows eight critical steps according to 3D3C-PIV volumetric measurement standards:

Step1-Optical Positioning:Defining the 3D measurement volume at the nozzle(Fig.3).

Fig.3

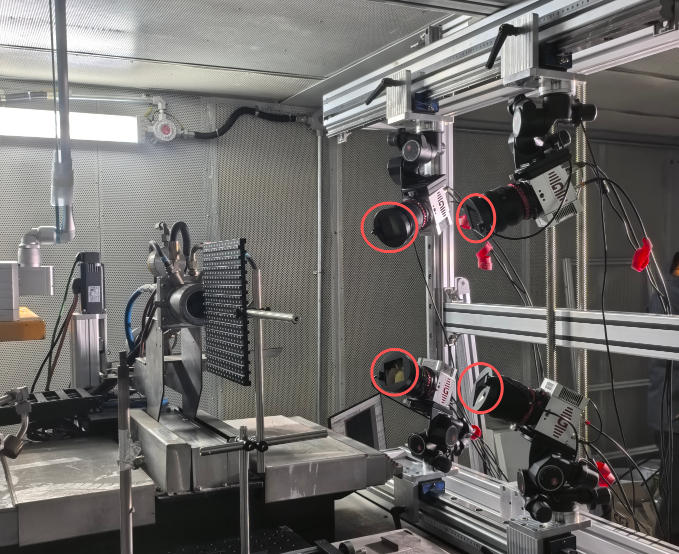

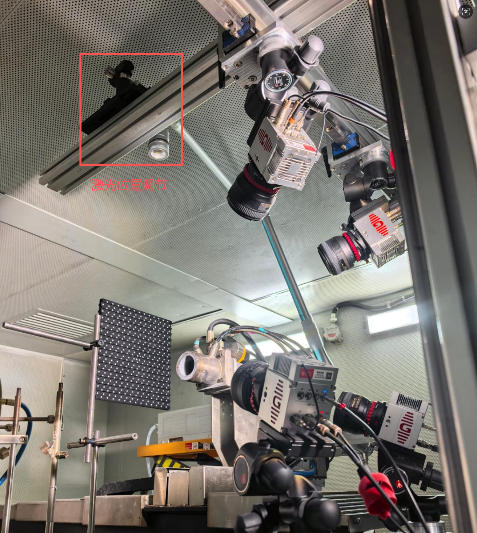

Step2-Geometric Arrangement: Positioning four Revealer High Speed Cameras for optimal field-of-view coverage(Fig.4).

Fig.4

Step3-Scheimpflug Adjustment: Using the Revealer Scheimpflug mechanism to ensure sharp imaging across the entire depth of the volume(Fig.5).

Fig.5

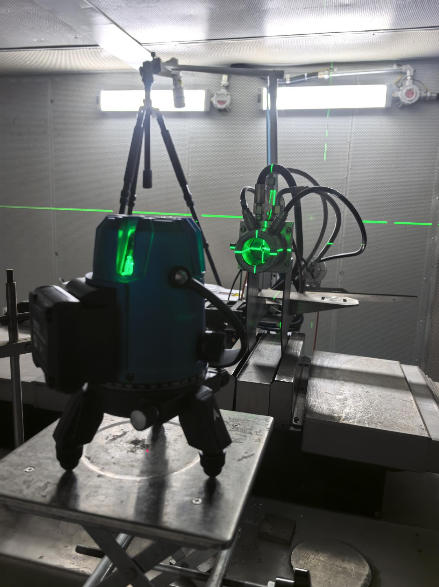

Step4-Laser Alignment: Uniformly covering the measurement area with volumetric laser illumination(Fig.6).

Fig.6

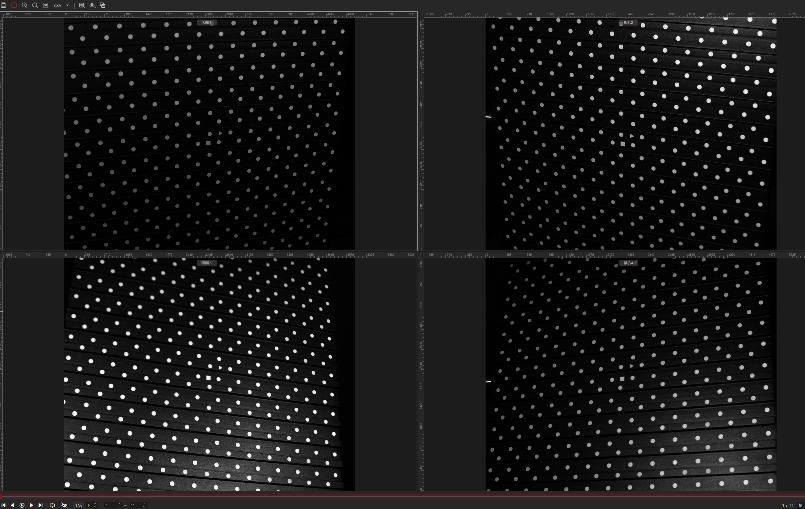

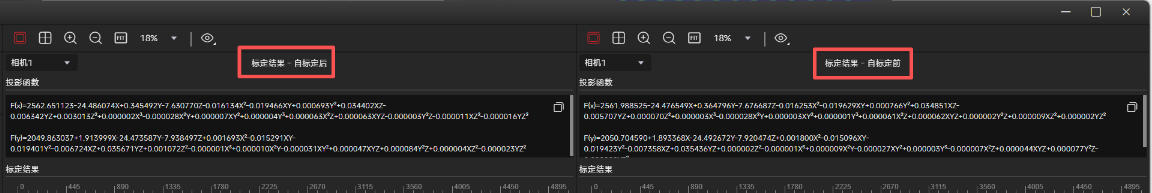

Step5-Initial Calibration: Establishing the mapping between pixel and physical coordinates with pixel-level accuracy(Fig.7).

Fig.7

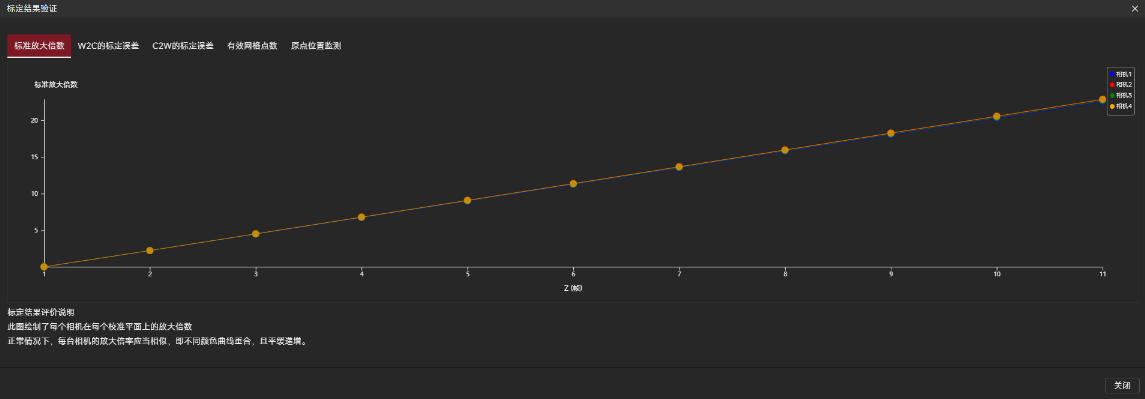

Step6-Volume Self-Calibration: Correcting the projection model to reduce spatial re-projection errors(Fig.8).

Fig.8

Step7-Synchronization Optimization: Finalizing the timing for the laser, Revealer High Speed Cameras, and liquid crystal shutter to suppress flame light(Fig.9).

Fig.9

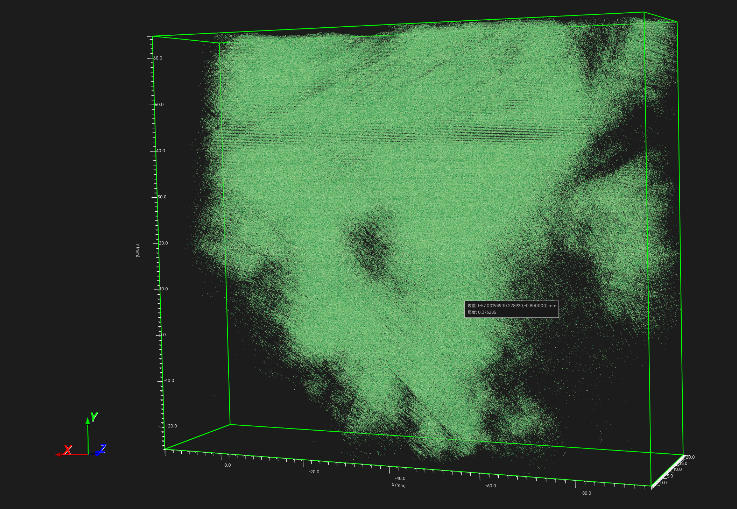

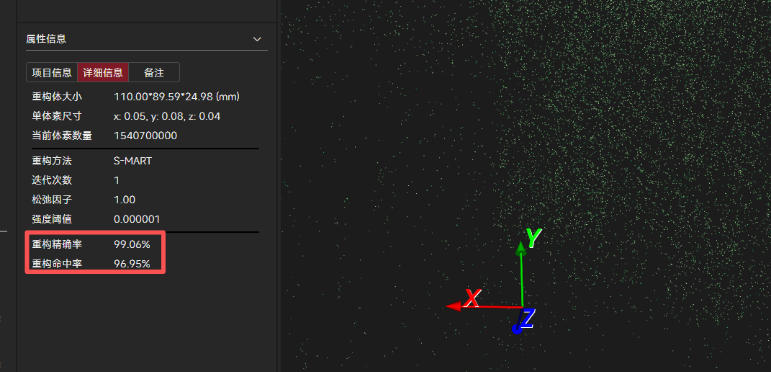

Step8-Reconstruction & Visualization: Using Revealer RFlow4 software for volumetric reconstruction and 3C velocity calculation.

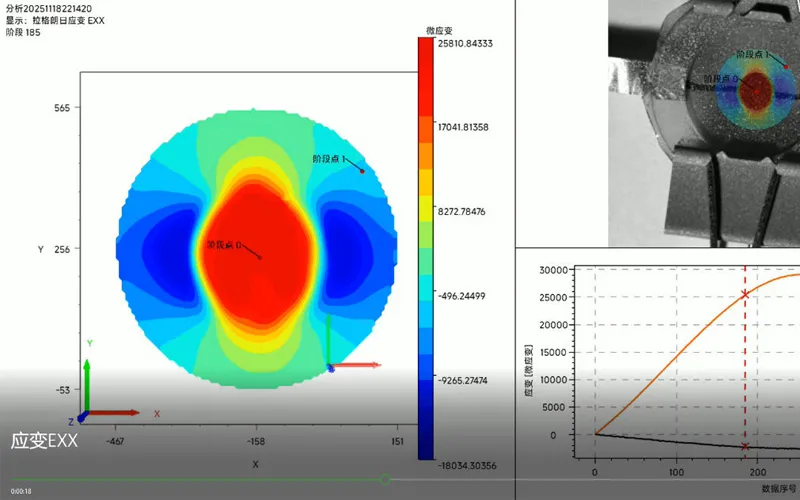

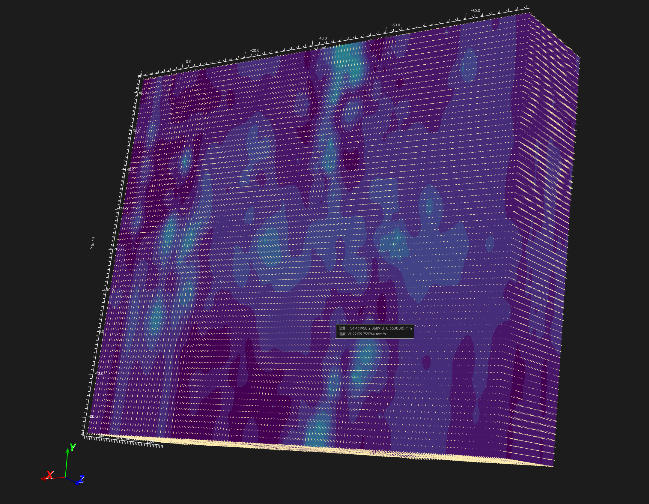

Precision: The particle hit rate during reconstruction remains above 95%, ensuring reliable spatial resolution(Fig.10~11).

Fig.10

Fig.11

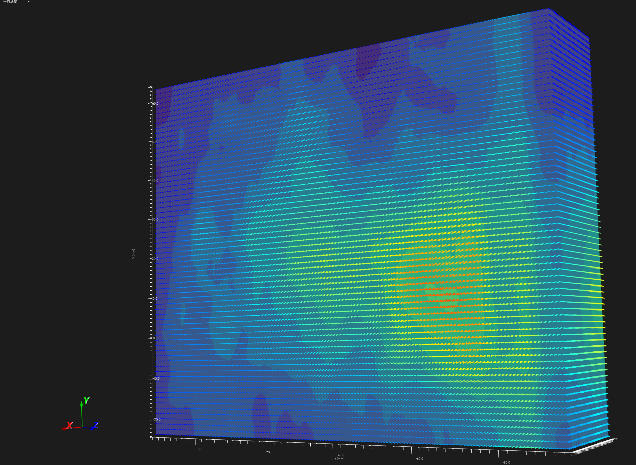

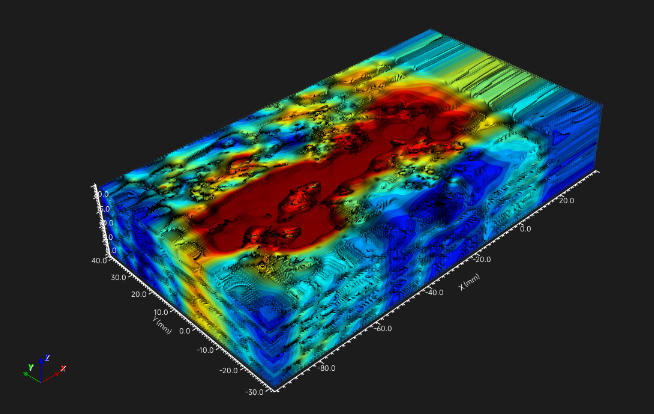

Time-Averaged Analysis: Identifies stable average velocity distributions and dominant flow structures like reflux zones(Fig.12).

Fig.12

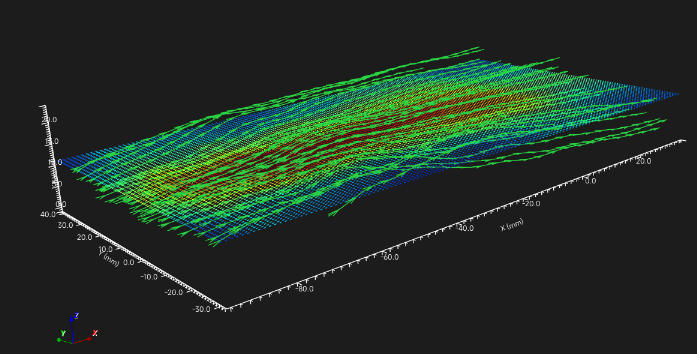

Instantaneous Velocity: Quantitatively observes spatial velocity distribution to identify jet core development and shear layer expansion(Fig.13).

Fig.13

3D Slicing & Streamlines: Visualizes 3D velocity gradients, structural continuity, and macro movement paths of the flame(Fig.14~16).

Fig.14

Fig.15

Fig.16

This experiment successfully reconstructed the 3D velocity field and vortex structures of a nozzle near-field using the Revealer 3D3C-PIV system developed by Agile Device. Validated in high-radiation combustion environments, the Revealer High Speed Camera and Particle Image Velocimetry (PIV) system offer distinct advantages in engineering adaptability and data stability, making them the premier choice for advanced combustion flame research.