Digital Image Correlation (DIC) is a non-contact optical method used to measure 2D or 3D deformation, vibration, and strain in materials. While low-speed cameras suffice for static tests, capturing dynamic events—Such as explosion, high-speed impact or vibration analysis—requires the precision of a professional high-speed camera.

In these scenarios, the camera isn't just recording a video; it's acting as a high-precision sensor.

To understand the foundational hardware behind these tests, see our The Ultimate Guide to High-Speed Camera Specifications.

Not every high-speed camera is suitable for DIC. To get usable data, your camera must meet three technical pillars:

DIC software works by tracking "speckle patterns" on the material surface. If the sensor produces too much electronic noise, the software will misinterpret pixel fluctuations as material strain, leading to "ghost data."

Revealer Edge: Our sensors are optimized for low-light stability, ensuring clean patterns even at microsecond exposures.

For accurate strain mapping, you need enough pixels to resolve the speckle pattern.

The Rule of Thumb: At least 3–5 pixels per speckle.

Learn how resolution impacts your testing in our High-Speed Camera Resolution Comparison.

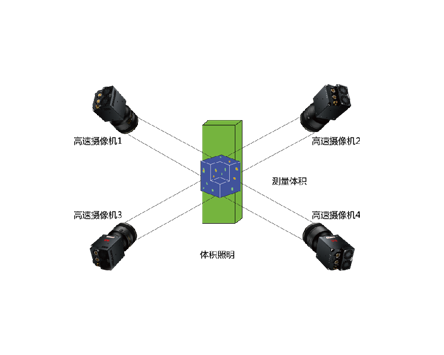

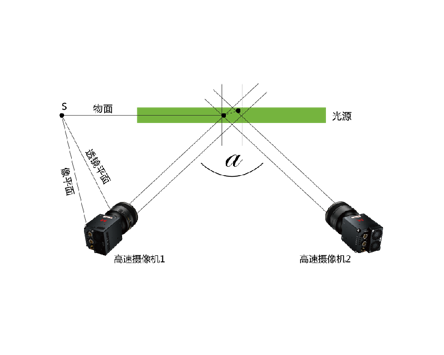

For 3D-DIC, two cameras must capture the frame at the exact same microsecond. Any "trigger jitter" will ruin the triangulation and the resulting 3D model.

Where does a Revealer High-Speed Camera truly shine in DIC?

Ballistic & Impact Testing: Measuring how a material absorbs energy during a high-speed collision.

Vibration Analysis: Tracking the resonant frequencies of turbine blades or automotive components.

Fracture Mechanics: Observing the millisecond-fast propagation of cracks in composite materials.

To maximize your data quality, follow this 3-step checklist:

Lighting: Use high-intensity LED cold lights to avoid heat-induced air turbulence, which can distort images.

Calibration: Use a high-quality calibration grid to "teach" the software the camera's lens distortion.

Frame Rate Selection: Ensure your FPS is at least 10x the frequency of the event you are measuring.

Need help calculating your required FPS? See our guide: How to Choose the Best FPS for Industrial Applications.

Our Ultra Series and M-Series cameras are designed with DIC in mind, offering:

Global Shutter Technology: Eliminates motion blur, ensuring every speckle is sharp.

High QE (Quantum Efficiency): Allows for shorter exposure times without losing image depth.

Seamless Software Integration: Compatible with major DIC software providers.

Q: Can I use a color camera for DIC?

A: Monochrome is preferred. Monochrome sensors provide higher contrast and better spatial resolution, which is essential for tracking speckles accurately.

Q: What is the minimum resolution for 3D DIC?

A: While 1MP (1280x1024) is the industry standard for many dynamic tests, our 5MP models offer superior detail for large-scale specimen testing.

Q: How much does a DIC camera system cost?

A: Costs depend on the required FPS and resolution. Request a Quote for a DIC-Ready System.

In the world of material science, accuracy is everything. By choosing a camera specifically optimized for the rigors of Digital Image Correlation, you ensure that your research is backed by reliable, high-fidelity data.