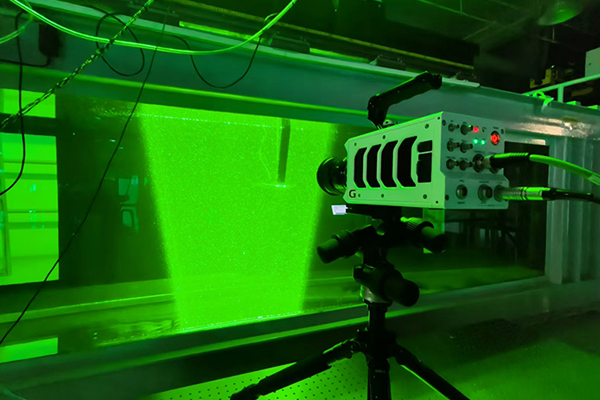

Understanding and minimizing error sources is critical for publishing high-quality PIV data. The primary sources of uncertainty in PIV include:

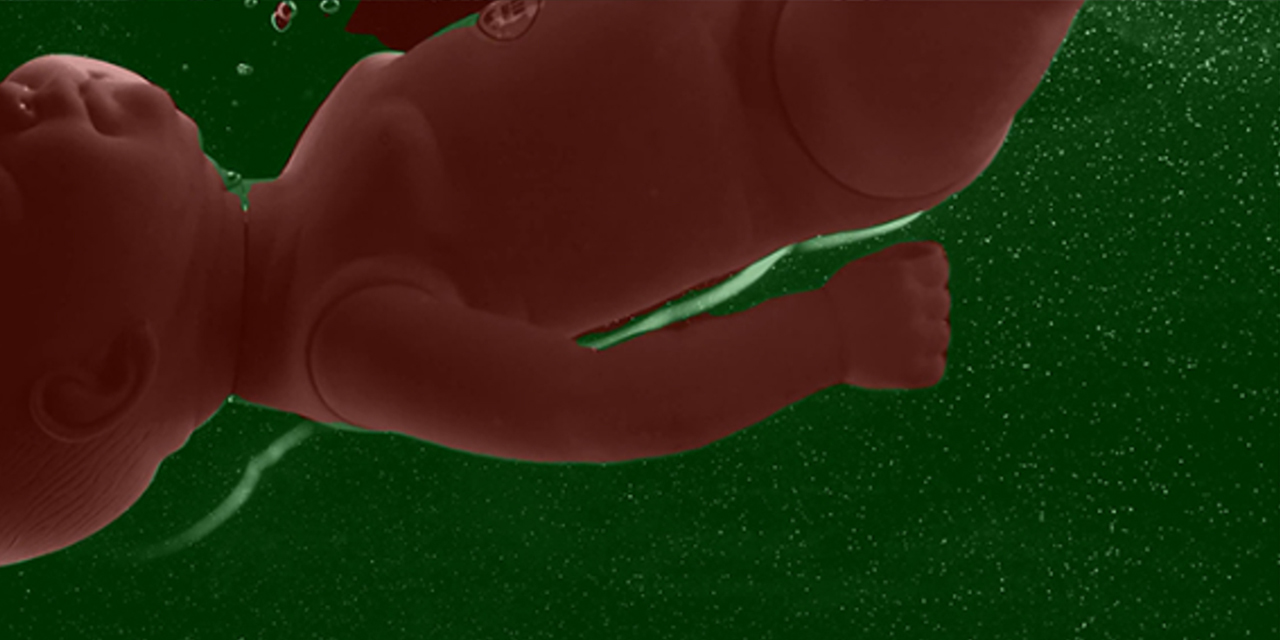

Tracer Particle Dynamics: Particles not faithfully following the flow (slip velocity, inertia, buoyancy).

Revealer’s Mitigation: We provide expert consultation on tracer particle selection and seeding density based on your fluid and flow regime, ensuring optimal traceability.

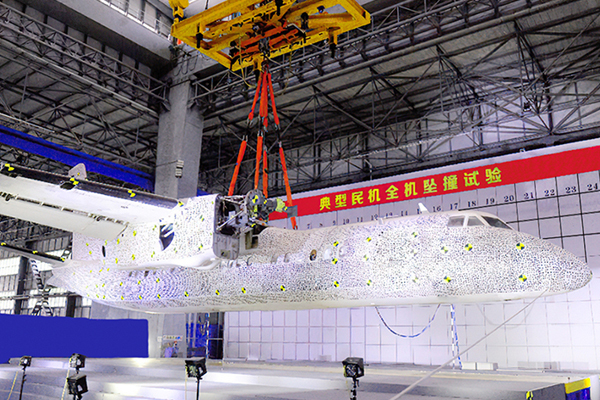

Optical Distortions & Calibration Errors: Misalignment between camera(s), lens distortions, and inaccurate mapping from image to world coordinates.

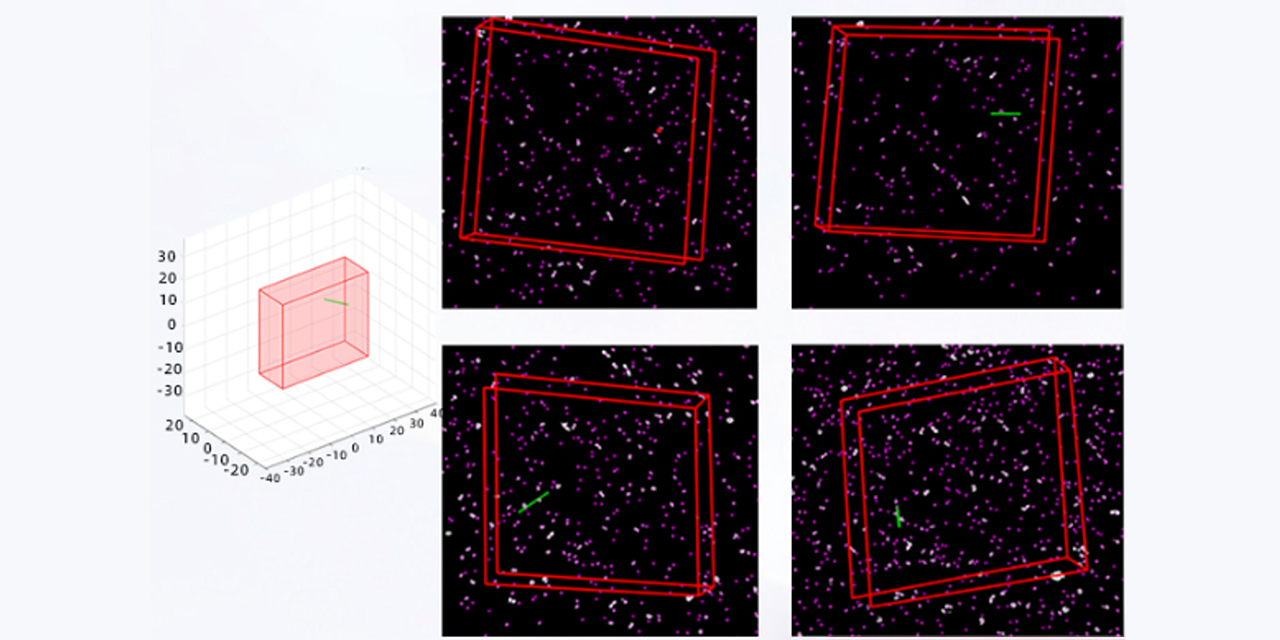

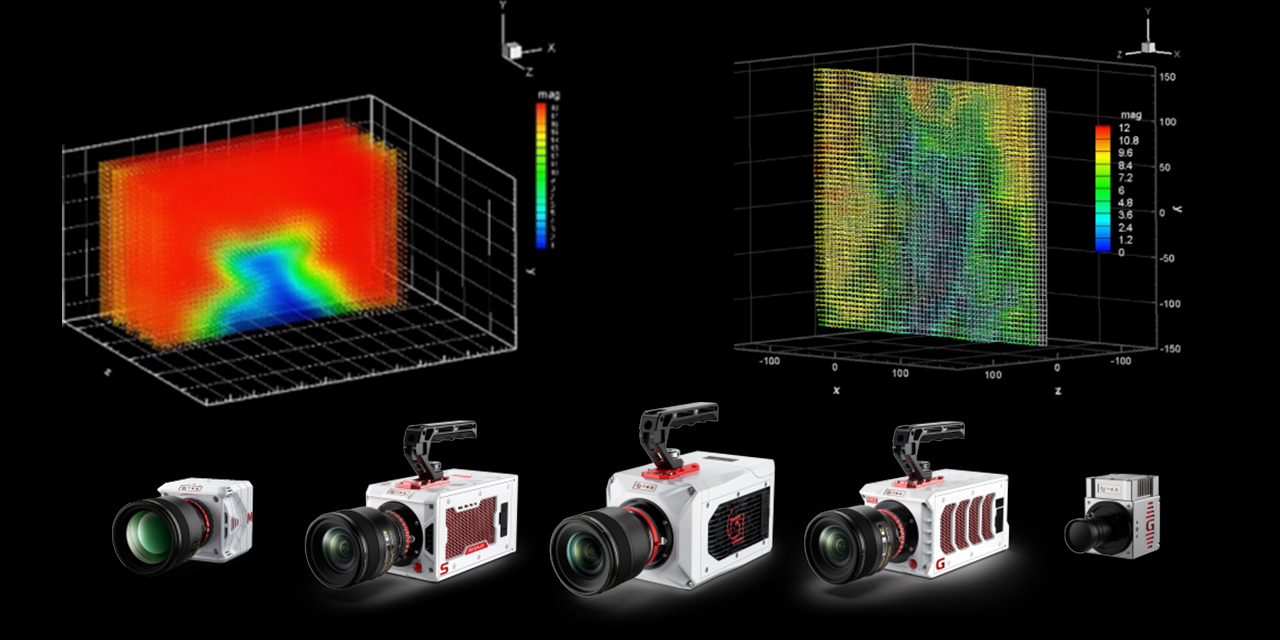

Revealer’s Mitigation: Our systems feature precision-matched optics and advanced self-calibration algorithms within RFlow software. For Stereo and Tomographic PIV, we utilize robust volume self-calibration techniques that automatically compensate for misalignments, delivering superior 3D reconstruction accuracy.

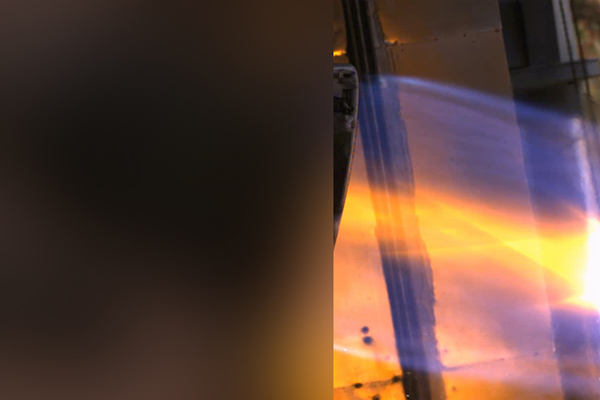

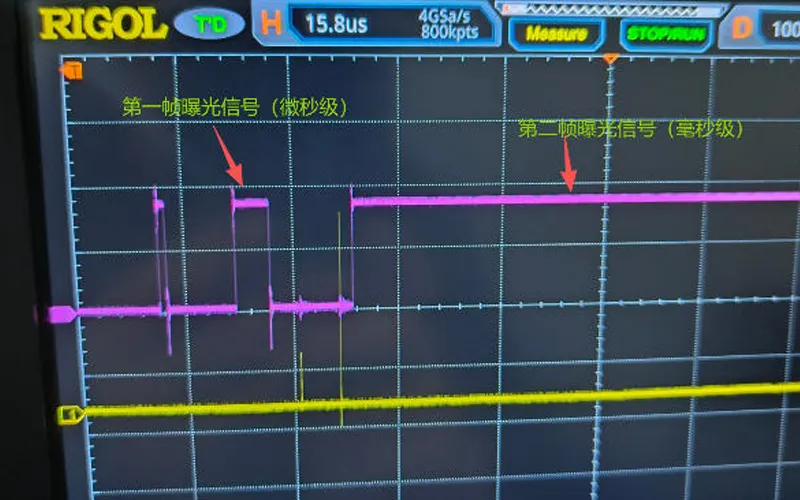

Synchronization & Timing Jitter: Imperfect synchronization between the laser pulse and camera exposure leads to blurred or biased particle images.

Revealer’s Mitigation: We employ high-precision, hardware-level synchronization controllers with sub-microsecond jitter. This ensures perfect “frame-straddling” capture of particle pairs, which is the foundation for accurate velocity calculation.

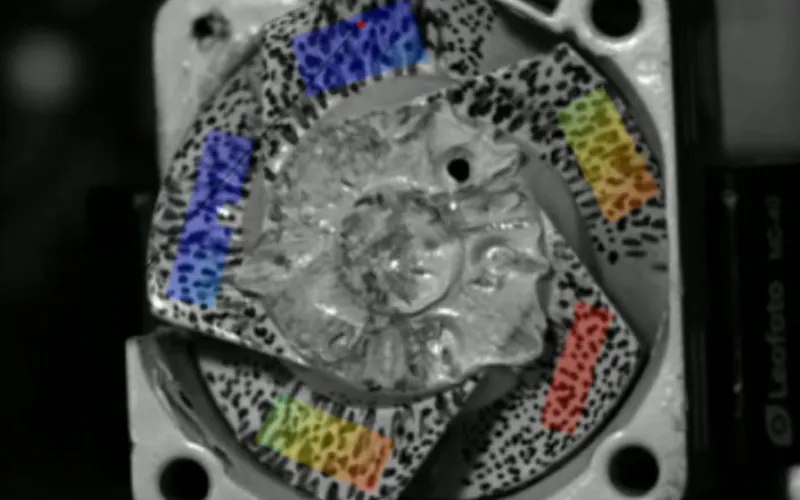

Processing Algorithm Limitations: Errors from interrogation window size, peak-locking effect, and out-of-plane motion in 2D PIV.

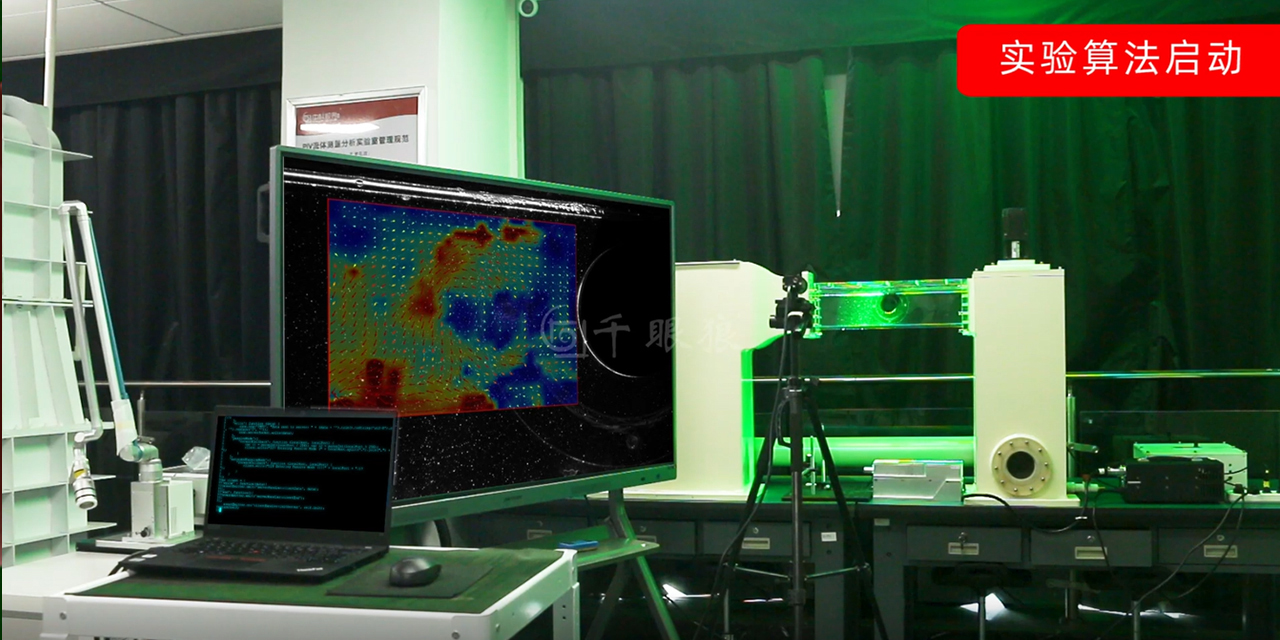

Revealer’s Mitigation: Our RFlow software implements state-of-the-art multi-pass grid deformation algorithms with sub-pixel interpolation. It includes tools to detect and minimize peak-locking, and provides comprehensive uncertainty quantification modules to statistically assess measurement confidence.

By addressing these errors at both the hardware design and software processing levels, Revealer PIV Systems are engineered to deliver data you can trust for critical research and development.